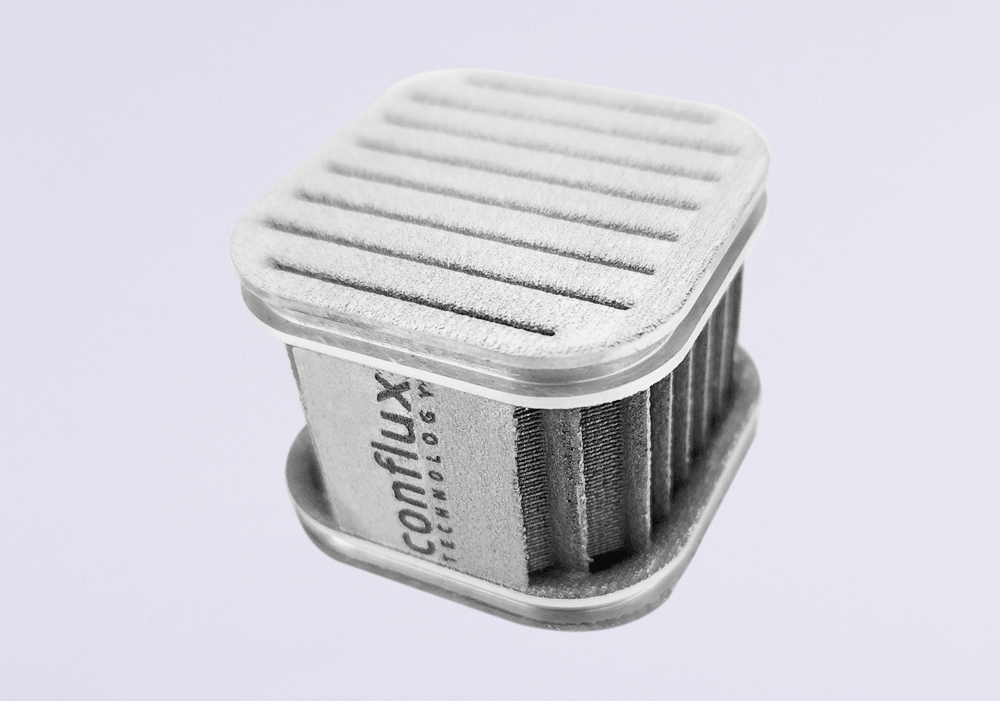

Heat transfer specialist Conflux Technology has added another new product to its commercial offering: a cartridge-based heat exchanger.

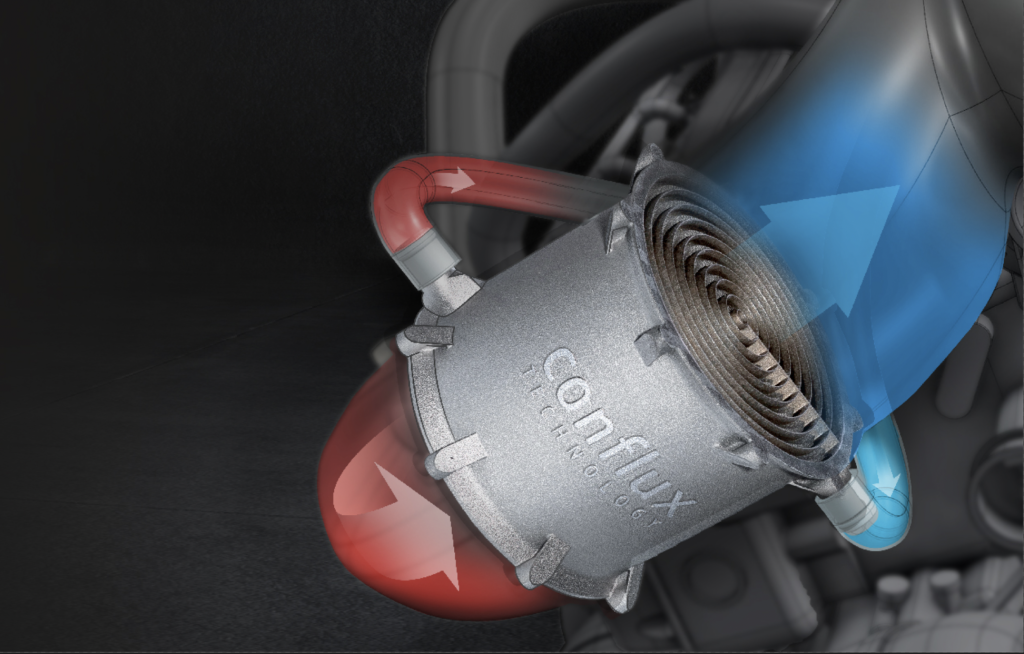

Conflux Technology’s latest launch, which is essentially a 3D printed core that can be embedded into traditionally-manufactured housings, is said to deliver fewer pressure-drops and higher heat transfer in a compact design. Given that the product can be scaled and configured to meet user needs, the firm anticipates it finding defense, aerospace, EV, automotive, industrial and energy use cases.

“The [device’s] embedded thermal transfer lowers plumbing volume, performance impact and risks,” explained Dan Woodford, CEO of Conflux Technology. “Our growing suite of Conflux products each offers features tailored to our customer’s specific application fluids and packaging requirements.”

‘Productization’ at Conflux Technology

Founded in 2017 by engineer Michael Fuller, Conflux Technology specializes in fostering 3D printing’s thermal and fluid management applications. Having worked in F1, World Rally Championship and Le Mans racing, Fuller’s career has largely seen him work in automotive, but he and his firm are now seeking to disrupt the wider heat exchanger market.

Since AM Ventures backed Conflux Technology five years ago, the firm has gone on to make significant advances within its R&D efforts. Leveraging the ‘Synchrotron’ particle accelerator, the company has come up with a means of inspecting parts at a sub-macroscopic level. In another initiative, meanwhile, the business has worked with Deakin University to develop new heat exchanger 3D printing materials.

Earlier this year, Conflux Technology partnered with GKN Aerospace as well, in a deal that’s set to see the latter’s technology used to create exchangers for European clients, which provide high-temperature parts with improved cooling efficiency.

However, with the launch of its 3D printed Water Charge Air Cooler earlier this year, the company changed strategy. Before introducing its first product, Conflux Technology had largely deployed its expertise within its application development, design, prototyping and low-volume production services. But it has now embarked on a ‘productization strategy,’ that has continued with the Conflux Cartridge.

Introducing the Conflux Cartridge

Drawing on its extensive heat exchanger R&D expertise, Conflux Technology’s latest product launch has seen it bring a versatile, compact core to market that can be integrated into other parts or casings. The device itself is designed to balance the thermal and hydraulic performance of complex temperature management systems across multiple applications.

Thanks to laser powder bed fusion (LPBF), Conflux Technology says it’s possible to 3D print the Cartridges scalably, affordably and to directly meet the needs of their end users. In practice, this means the size and performance of the heat exchanger can be set according to customers’ performance priorities, and it can be configured specifically to handle their systems’ fluids and physical constraints.

According to Conflux Technology, its proprietary core also has tiny structures and internal geometries which can only be achieved with 3D printing, a technology that provides precise control over the ratio of surface area presented to each individual fluid, as well as optimizing aspects like heat transfer, turbulence and pressure drops.

In terms of applications, the Cartridge is expected to prove particularly useful in systems where fowling or regular inspection must be accommodated, as they can easily be swapped out, and the firm says that those who replace legacy cartridges with its latest product, stand to benefit from significantly improved performance.

“Our customers continue to be impressed with the fine details we are manufacturing with our advanced techniques and our patented technology,” Ben Batagol, Conflux Technology’s Head of Business Development, added after his recent trip to Formnext. “We are excited to be able to show how this level of performance is possible in such a compact package.”

Conflux Technology is no doubt pushing heat exchanger design forward, but it’s far from the only firm using 3D printing to do so. Late last year, for instance, 3D Metalforge 3D printed heat exchanger parts for Shell. Now installed at Shell’s site on Jurong Island, the durability-enhanced components have helped minimize equipment downtime there.

In the past, the likes of GE Research have also worked with engineers at the University of Maryland and Oak Ridge National Laboratory to create a heat exchanger that’s resistant to temperatures of up to 900°C. The 3D printed device features a unique grape-like geometry, which provides it with the extreme heat and pressure resistance needed to outperform state-of-the-art devices by over 200°C.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Conflux Technology’s new Conflux Cartridge. Image via Conflux Technology.