Heat exchanger 3D printing specialist Conflux Technology has announced the closure of a $8.5 million (AUD) financing round, in addition to a significant advance within its R&D workflow.

By adopting Australia’s ‘Synchrotron’ particle accelerator, the firm has found a way to identify hidden anomalies within 3D printed parts, and inspect heat exchangers at a sub-macroscopic level of detail. With its newly-raised cash, meanwhile, the company says that it aims to accelerate its “transformation from R&D into fully-fledged production,” as well as the roll-out of “long-held plans” for its offering.

“The investments will enable us to significantly increase our capacity and capability,” said Conflux Technology CEO, Michael Fuller. “We will be increasing the number of metal AM machines and investing in the latest series-production platforms, continuing to grow our team and furthering our vertical integration with final post-processing of parts.”

A ‘thermal technology pioneer?’

Founded in 2017 by Michael Fuller, an engineer and designer of Formula 1, World Rally and Le Mans-winning race cars, Conflux Technology prides itself on being a “thermal technology pioneer.” To take what he learned about heat exchangers from the world of racing into other industries, Fuller has adopted metal 3D printing, a process which his firm now uses to create optimized thermal management parts.

Specifically, Conflux Technology leverages computational heat transfer simulation alongside its processing expertise, to deliver exchangers to clients in the automotive, defense, aerospace and oil & gas sectors, with unique designs that provide them with quality, performance, cost and lead time benefits, compared to conventional devices.

The company also offers customers an arsenal of engineering services, which range from initial product design right through to post-processing support. With its FEA simulation tools, for instance, Conflux Technology is able to evaluate a part’s durability prior to production, while its CFD simulation offering is said to yield insights into a product’s properties, which enable clients to minimize print errors.

Conflux Technology’s R&D advance

According to Conflux Technology, its 3D printing-led approach yields heat exchangers with significant geometrical advantages, that aren’t possible to achieve via brazing or subtractive manufacturing. However, the firm adds that these benefits also bring challenges, as optimized monolithic parts often feature complex internals, which make assessing the probability of thin wall failures difficult.

To get around this drawback, the company has turned to the ‘Synchrotron’ located at the Australian Nuclear Science and Technology Organization’s (ANSTO’s) Melbourne facility. About the size of a soccer pitch, ANSTO’s circular particle accelerator essentially fires electrons through a series of interconnecting tunnels, to produce intense beams of light, over a million times brighter than the sun.

Using magnetic fields, the Synchrotron forces these electrons into a circular orbit, in which they can be perturbed at certain points, creating infrared radiation and intense X-rays that are channelled into various instruments. In Conflux Technology’s case, it has found a way to harness this technology, as a means of improving the resolution and scale with which it’s able to inspect heat exchangers.

To help sift through the vast cross section data provided by Synchrotron experiments, which can yield up to a terabyte of information, the firm has developed ‘Conflux Quantify’ analysis software. Using its proprietary program, the company says it’s now able to precisely assess the wall thickness, surface roughness and feature accuracy of a given part, while detecting structural weaknesses earlier than before.

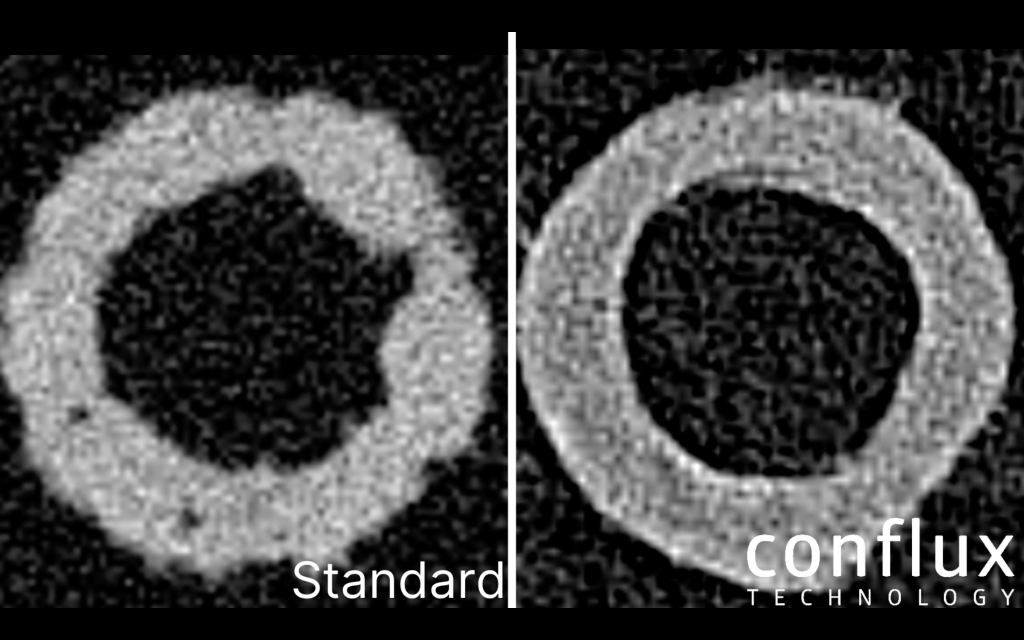

In order to showcase the benefits of its approach, Conflux Technology has shared images of two micro tubes, one that was conventionally built, and another created via particle accelerator gleaned parameters (below). The latter not only has better density and a more consistent form, but the firm says its enhanced workflow made parameter verification easier, allowing the part’s lead time to be minimized.

AM Ventures’ continued backing

Since its R&D breakthrough, Conflux Technology has also completed a Series A funding round, in which long-term supporter AM Ventures and finance firm Acorn Capital have backed it with $8.5 million (AUD). AM Ventures launched a €100 million VC fund to support 3D printing start-ups earlier this year, and the firm has a storied history of accelerating the development of the sector’s most promising businesses.

In the past, the company has ploughed $5.5 million into 3YOURMIND as well as contributing to DyeMansion’s $14 million funding round, and it also provided Conflux Technology’s seed funding back in 2017. At the time, the heat exchanger specialist said that the capital would allow it to advance the functional applications of its technologies, and it has since turned their promise into quantifiable benefits.

“Highly-complex geometries enabling a more efficient thermal management in order to reduce energy consumption and waste of materials, require highly-qualified experts who are capable of mastering the best manufacturing technologies and software tools,” said Arno Held, Managing Partner at AM Ventures. “This is exactly what makes the Conflux team unique in this world.”

“Heat exchangers are one of the biggest applications in 3D printing.”

According to Conflux Technology itself, its investment round success reflects the advances it has made in the design and application of 3D printed heat exchangers. The firm also cites its ability to address the needs of aviation, microelectronics and motorsport clients, as being key to the backing it has received, and hails its investors as being “renowned for their selective investments.”

“We are thrilled to have partnered with such experienced and successful investors,” concluded Fuller. “Both Acorn and AM Ventures have enviable track records in accelerating businesses to scale and enabling transformative technologies that have positive impacts on our world. We look forward to a very exciting next chapter in Conflux’s journey.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Australia’s ‘Synchrotron’ particle accelerator. Photo via ANSTO.