CECIMO, the European Association of the Machine Tool Industries, has published an Activities Report summarizing the many events, projects and advocacy initiatives taken in the past year to promote the interests additive manufacturing across the continent.

The report includes a counter act on EU Eco-Design rules posed to add undue restrictions of AM systems; a push to include additive manufacturing in the EU Machinery Legislation; and progress reports on ongoing research & development projects such as the large-scale KRAKEN Project in collaboration with AITIIP, FIAT, TWI and VERO Software.

In addition, UK based engineering company and additive specialist Renishaw has also declared renewed contribution to CECIMO in light of the UK’s withdrawal from the European Union.

Getting 3D printing represented in the wider manufacturing industry

CECIMO published its European Additive Manufacturing Strategy in June 2017. Based on the driving principles outlined in the document, the association reports a number of successful advocacy initiatives accomplished in the last year.

Each initiative was taken to ensure that additive manufacturing achieves accurate representation in European regulation, avoiding any legislative setbacks to the technology’s progress.

In the first instance, CECIMO successfully overturned proposed machine tool design requirements for additive manufacturing systems as outlined by the European Commission. “The inclusion of AM machines in the scope of this draft regulation would have added an excessive burden on the machine manufacturers,” states the report.

“Moreover, these draft rules would have asked for additional information on energy consumption that ignores the customized nature of AM machines and machine tools in general, which are tailored to the specific client needs.”

In second instance, CECIMO succeeded in laying the foundations for establishing harmonized health and safety (H&S) requirements for AM machines.

And in the third and final advocacy initiative, CECIMO has confirmed that it is working with appropriate commission departments to improve the classification of industrial 3D printers. “Currently, the HS does not make a distinction between AM machines working with metals and those working with other materials, such as ceramics or plastics,” states the report.

“This inclusive section makes it impossible to accurately trace the trade transactions of metal AM machines, resulting in imprecise statistics, which are crucial to better grasp the growth potential of additive technologies.”

Project updates

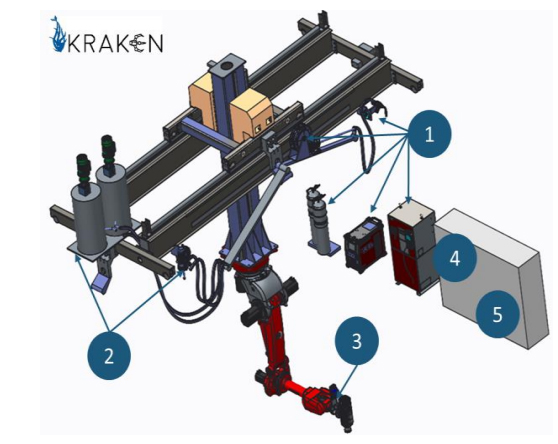

In KRAKEN, CECIMO is helping automotive partners build a multimaterial hybrid additive manufacturing machine that can make parts up to 20 meters in length.

The association is also due to publish the result of it AM-Motion project “identifying barriers for the industrialization of AM in Europe” and “mapping gaps on standardization”. Conducted in collaboration with Materialise, Airbus, Siemens,

TNO, Prodintec, CEA and TWI, the AM-Motion report will also identify areas of skills shortage to help deliver appropriate upskilling and training.

Renishaw’s support in light of Brexit

Stewart Lane, General Manager of Renishaw’s UK Sales Division was appointed to the board of CECIMO and fellow CECIMO member the Manufacturing Technologies Association (MTA) in 2016.

Renewing its backing of the association, the company has issued a press release in which Lane states, “Renishaw is looking at how it can further support CECIMO and the good work it does,”

“It is important for UK industry to have close ties and representation in Europe, in a time when relationships are changing. This means Renishaw’s relationship with CECIMO is more important than ever before.”

CECIMO’s full Activities Report for 2017 can be accessed online here.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your entries now with the chance of winning a 3D printer and attending this year’s annual dinner.

To stay up to date with all the latest AM activities subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows CE certification in Europe graphic. Image via CECIMO