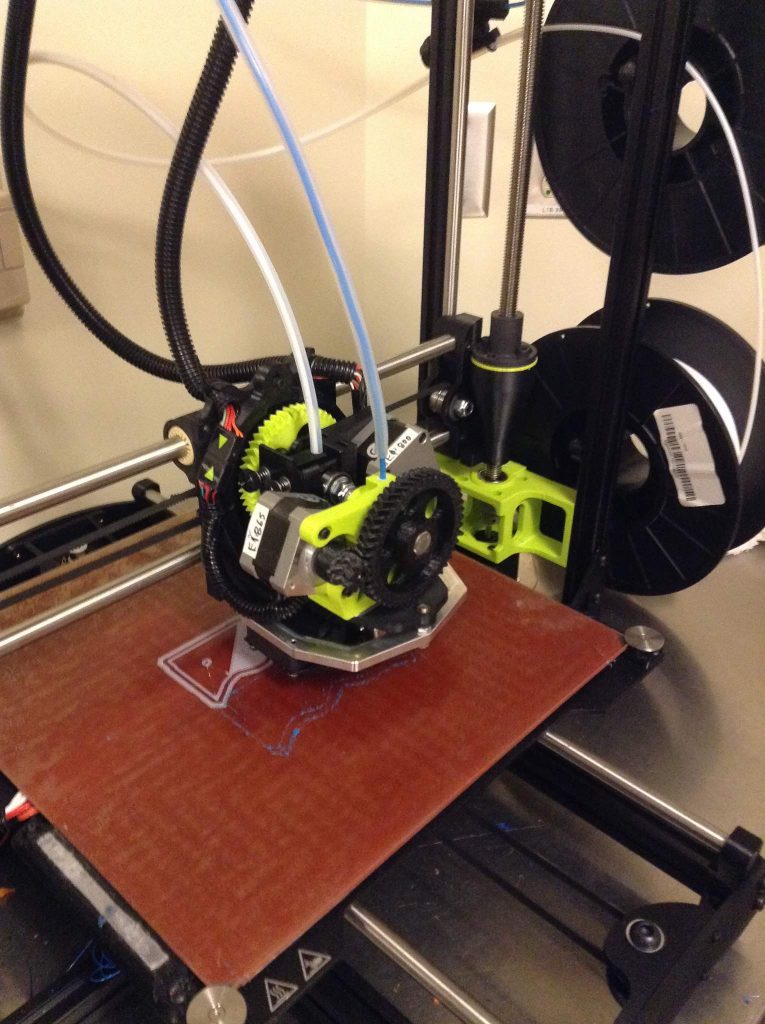

Banner Health is using the LulzBot TAZ 6 to incorporate 3D printed parts into its cancer treatment. Starting with North Colorado Medical Center’s Cancer (NCMC) Institute, Banner Health will use the, “3D printer to enhance treatment for cancer patients undergoing radiation.”

Earlier this month, NCMC’s Oncology Department began treating its first skin cancer patient using 3D printed molds known as bolus.

“The sky’s the limit when it comes to 3D printing,” said Dr. Alexander Markovic, Medical Physics Program Director for NCMC’s Radiation Oncology. “With the 3D printed bolus, we are able to better target the radiation dose so that the treatment is more effective.”

Pioneering 3D printing program

Markovic and his team pioneered the new 3D printing program at NCMC’s Cancer Institute, paving the way for providers to roll out the program at Banner MD Anderson Cancer Center in Gilbert, Ariz., as well as McKee Medical Center in Loveland, Colo., in the coming months.

After receiving the LulzBot TAZ 6 in December from Loveland-based Aleph Objects, Inc., Markovic and his team underwent several months of training and testing before applying it to a treatment plan this spring.

Darrell French, an Eaton resident, is more than halfway through 6-weeks of radiation treatment after surgeons removed cancer from the inside of his ear. In preparation for the treatment, Markovic and his team used modeling from CAT scans to print a bolus that wraps around the outside and inside of French’s ear.

3D printed with NinjaFlex filament

Made from NinjaFlex flexible filament, the bolus ensures the radiation is applied to the right area in the right dosage amount. “It works really well and it hasn’t bothered me at all,” French said. “After three weeks, the inside of my ear is fine.” Prior to using a 3D printed bolus, Markovic said less precise materials such as gauze and tape have been the resources available to cover and cup the treatment area, which created air pockets that diluted the radiation dose.

With 3D printers, however, doctors can create a bolus in six to eight hours with 0.5-millimeter accuracy. “In the past, we resorted to using simple techniques such as gauze or rubber-like elastic materials to help better distribute radiation dose onto the patient’s skin surface,” said Jeffrey Albert, MD, who specializes in radiation oncology with Banner Health.

Increasing use of desktop 3D printers for end-use applications

“The new 3D printer allows us to create custom molds that perfectly conform to a patient’s skin, ensuring more accurate and timely treatment delivery.” Markovic said that while the 3D printed bolus isn’t a solution for all types of cancers or patients, using it for radiation treatment is the just the beginning. His team is also printing 3D body parts to demonstrate various treatment plans to patients as well as planning to use it for treating other types of cancer, such as breast cancer.

“Desktop 3D printers are increasingly being adopted for end-use applications,” Aleph Objects President Harris Kenny said. “Providing highly personalized care from a doctor’s desktop is an exciting example of what is possible with 3D printing in healthcare and other fields.”

As reported earlier, researchers are increasingly studying the use of desktop 3D printers to understand how new applications for functional engineered systems are possible.

Aleph Objects were nominated for a 3D Printing Industry Award by our readers, to vote for the company follow this link.

For all the latest news about the 3D Printing Industry, subscribe to our free newsletter and follow our active social media accounts.

Featured image shows Dr. Markovic and Darrel French, the first patient to receive the treatment.