A research team from the University of Waterloo’s School of Architecture has created what is thought to be Canada’s first 3D printed masonry wall.

Named Hive, the modular wall consists of 175 unique blocks of 3D printed clay and was commissioned by SDI Interior Design on behalf of its client, the Investment Management Corporation of Ontario (IMCO). It’s now used as a permanent showpiece on the 24th floor reception area of the company’s office space at 16 York Street in Toronto.

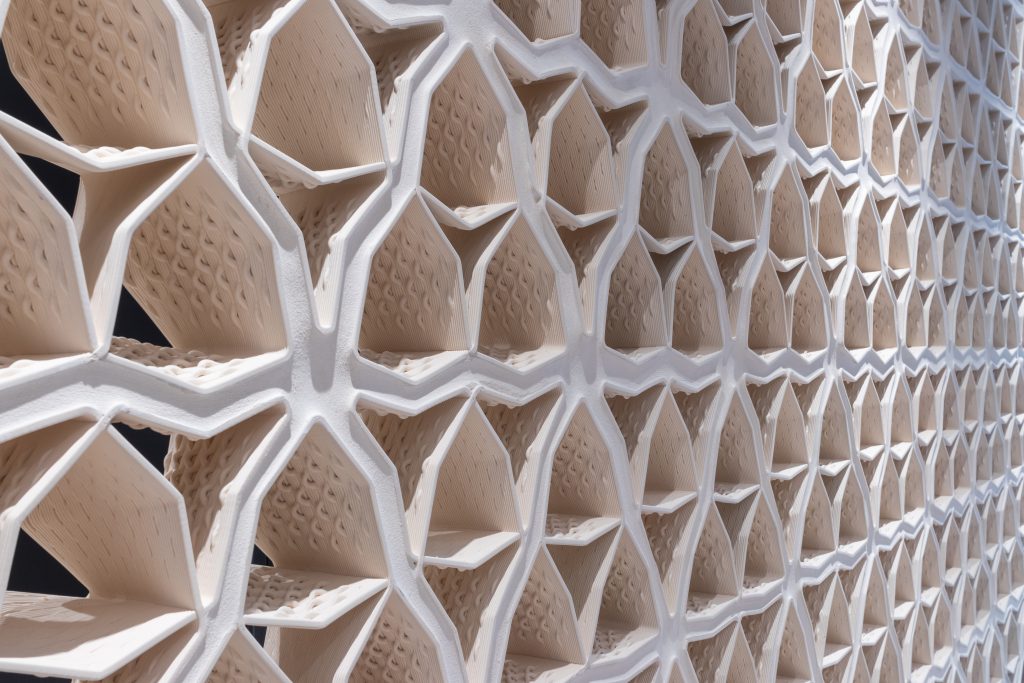

The project combines traditional ceramics and computational design methods with the production capabilities of extrusion-based additive manufacturing, resulting in a honeycomb-esque structure that’s both strong and material-efficient.

Crucially, the Hive wall utilizes the natural properties of the clay printing material, leveraging its fluidity and malleability in its wet form to shape the geometries and surface qualities of the units.

3D printing in architecture and construction

David Correa, an Assistant Professor specializing in bio-inspired architecture and one of the researchers working on Hive, sees a bright future for 3D printing in the architectural world.

Additive manufacturing’s unmatched geometric capabilities enable users to create a virtually limitless number of abstract geometries, paving the way for both functional and aesthetic creativity in construction. From an economical point of view, the technology also has the potential to quickly fabricate large and material-efficient structures while eliminating the need for tooling and manual labor, allowing for high productivity and lower costs.

The University of Waterloo isn’t the first to realize these benefits, as researchers at the Graz University of Technology (TU Graz) have been investigating how concrete 3D printing can enable huge material and CO2 savings for years now. Specifically, a team from the University’s Institute of Structural Design recently turned to 3D printing to create concrete elements that are significantly lighter than conventional building slabs.

Back in April, Dutch architecture firm Aectual worked with UAE-based architecture studio Pragma to fabricate a 3D printed recyclable pavilion for the Floriade Expo 2022. Spanning 8,880 square feet, the UAE Pavilion contains 3D printed facades and perimeter walls that reflect the claustra pattern, a typical architectural feature seen within urban environments in the UAE.

The artistic engineering of Hive

The Hive development team reportedly operated on an iterative design and fabrication process, whereby a combination of digital and physical models was used to create both the masonry units and the overall wall design.

According to the designers, they had to formulate their own clay mixes especially for 3D printing, as well as test the materials extensively and create several mock-up assemblies to study the feasibility of the build. The geometry of the masonry units was computationally designed.

Looking closer, each of the 3D printed clay units is hexagonal but together, they combine to form triangular building blocks. The wall as a whole is described as a series of opening and closing apertures, resulting in an ebb and flow of privacy and light – abstract features made possible only by the design freedom of 3D printing technology.

In the project documentation, the team writes, “This approach embraces the spirit of traditional ceramic craft with robotic precision, offering new avenues for material expression and geometric complexity within this field.”

The Hive project was born of a research partnership between the University of Waterloo and the IMCO. It also received technical and financial support from the Masonry Works Council of Ontario.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a close-up of the Hive wall. Photo via University of Waterloo.