A three-dimensional bioprinting technique is being used to make artificial vessels from scratch. A team from Brigham and Women’s Hospital (BWH) has made progress in fabricating blood vessels. The researchersused a 3D bioprinter to make afiber template to serve as the mould for the blood vessels. Thisimportant biomedical research has been supported by the National Institutes of Health, Australian Research Council and other leading Australian institutions.

Ali Khademhosseini, PhD, biomedical engineer, and director of the BWH Biomaterials Innovation Research Center said: “Engineers have made incredible strides in making complex artificial tissues such as those of the heart, liver and lungs. However, creating artificial blood vessels remains a critical challenge in tissue engineering. We’ve attempted to address this challenge by offering a unique strategy for vascularisation of hydrogel constructs that combine advances in 3D bioprinting technology and biomaterials.Our approach involves the printing of agarose fibers that become the blood vessel channels. But what is unique about our approach is that the fiber templates we printed are strong enough that we can physically remove them to make the channels. This prevents having to dissolve these template layers, which may not be so good for the cells that are entrapped in the surrounding gel.”

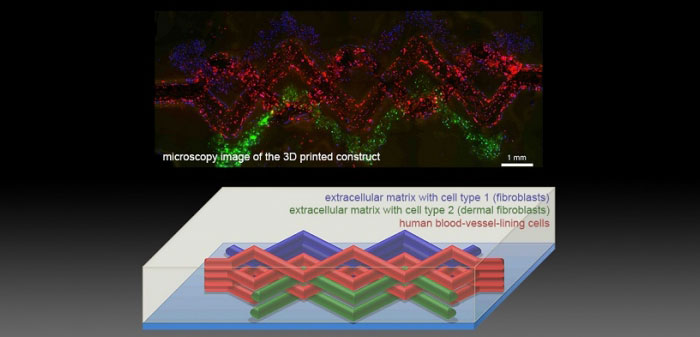

The researchers first used a bioprinter to construct afiber template to serve as the mould for the blood vessels. The mould was made using a polysaccharidepolymer called agarose, a material generally extracted from seaweed. Then the team covered the mould with a gelatin-like substance called hydrogel. This formed a cast over the mould, which was then reinforced via photocrosslinks.

Khademhosseini and his team constructed microchannel networks exhibiting various architectural features, which they were able to successfully embed these functional microchannels inside a wide range of commonly used hydrogels at different concentrations. One particular example, methacrylated gelatin laden with cells,was used to show how their fabricated vascular networks functioned to improve cellular viability, mass transport and cellular differentiation. Notably the technique also produced the formation of endothelial monolayers within the fabricated channels.

“In the future, 3D printing technology may be used to develop transplantable tissues customised to each patient’s needs or be used outside the body to develop drugs that are safe and effective,” said Khademhosseini.

The full study is available in the journal Lab On A Chip, which you can access here.