The Naturalis Biodiversity Center, a national research institute for biodiversity located in the Netherlands has used 3D printing and 3D scanning to help reconstruct a triceratops skeleton. Using the Builder Extreme 1500 PRO 3D printer from Builder 3D Printers, Naturalis was able to replace the missing bones of a new exhibit using scans of other triceratopses.

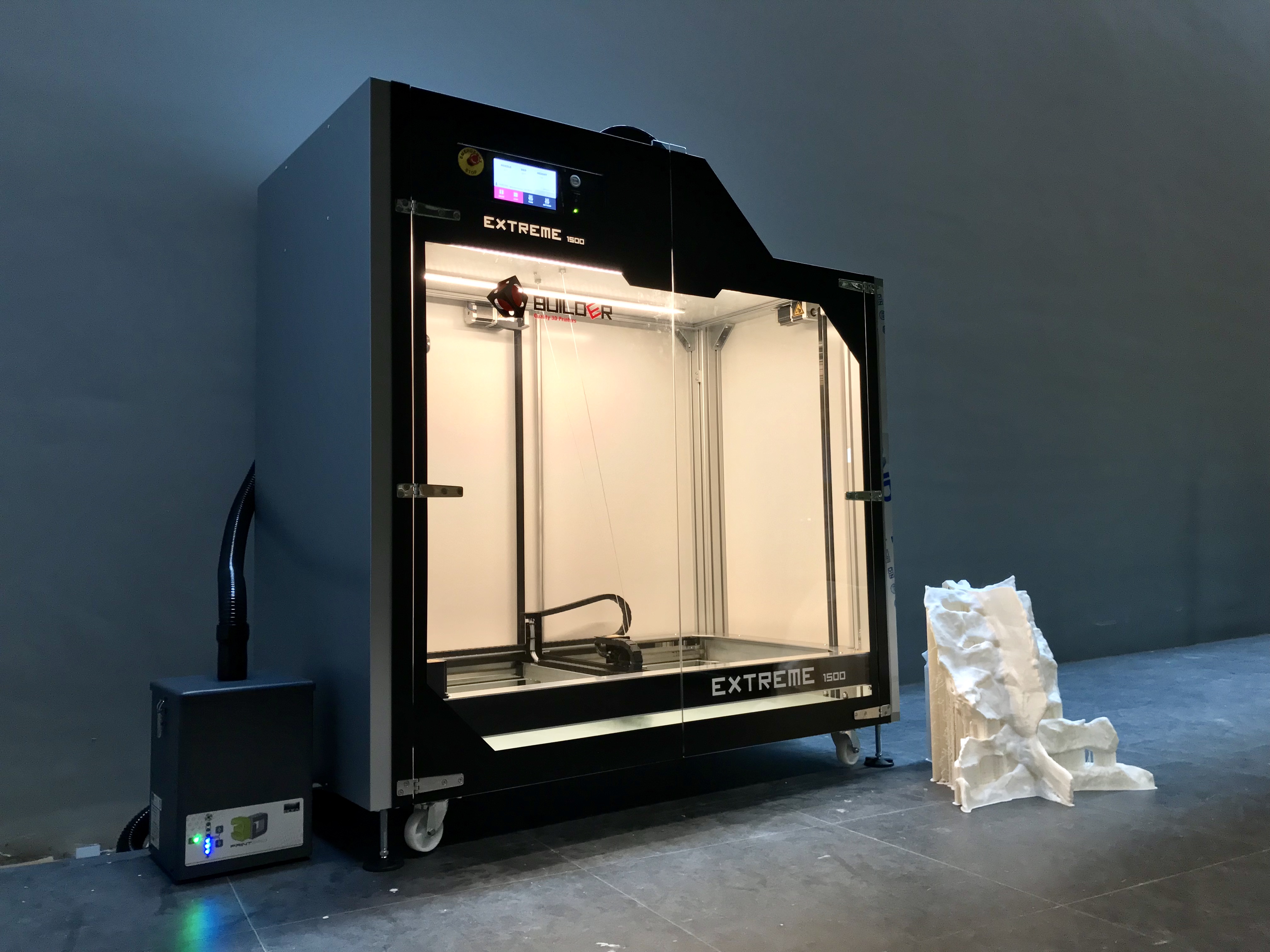

The triceratops, named Dirk, is now on display in the dinosaur gallery of Naturalis’ new museum in Leiden, which has been under construction for two years. Also on display at the LiveScience gallery is the Builder Extreme 3D printer that Naturalis used to reconstruct Dirk.

“Modern day palaeontologists use 3D imaging and printing techniques as an instrument to reconstruct fossil remains that are discovered in scientific excavations,” explains Dr. Peter H. Schalk, Director of Public and Markets at Naturalis.

“An industrial Builder Extreme 3D printer is deployed in the LiveScience gallery of the new Naturalis museum as an ongoing demonstration to the public how missing parts are printed and fitted in dinosaur skeletons.”

Builder 3D printing meets large-scale demands of Naturalis

Naturalis is home to a vast natural history collection, spanning over 42 million different objects. As well as Dirk, the collection also includes a 66 million year old T. rex skeleton which was discovered in 2013 in Montana, and various other dinosaur specimens. The skeleton of Dirk was dug up near Newcastle, Wyoming, and is estimated to be around 67 million years old.

Paleontologists working on Drik’s skeleton identified a number of missing bones, including some ribs, one of the horns and a large part of the skull. As Naturalis wanted to display the triceratops skeleton in its new museum, they decided to reconstruct these missing parts.

The Center has been using 3D printing for the past two years, producing only small parts on desktop sized systems.“This works perfectly fine if you only need 3D prints of a handful of smaller bones, and for a single larger bone, combining a couple of smaller prints isn’t too much of a hassle,” comments palaeontology prof. Anne Schulp, researcher at Naturalis.

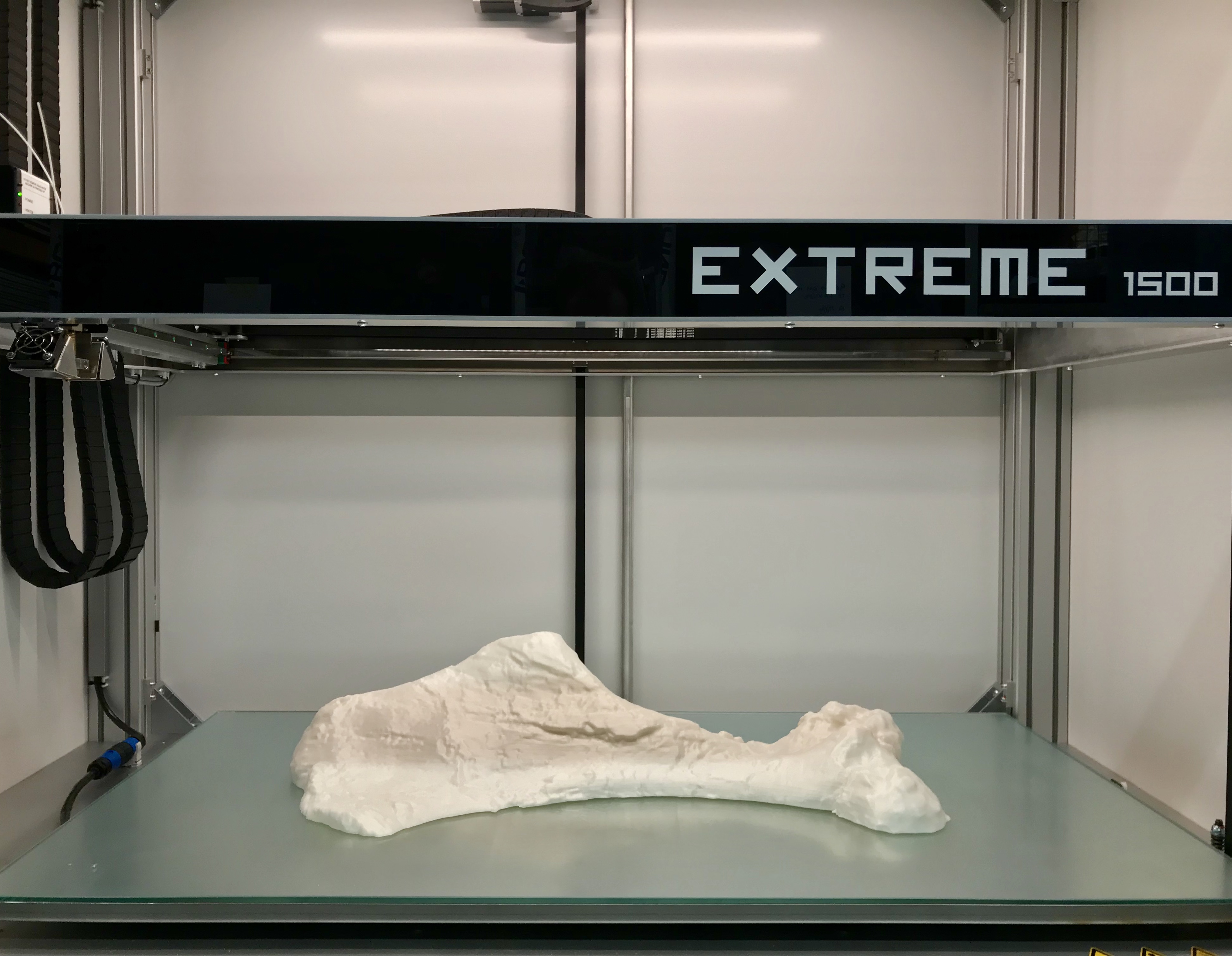

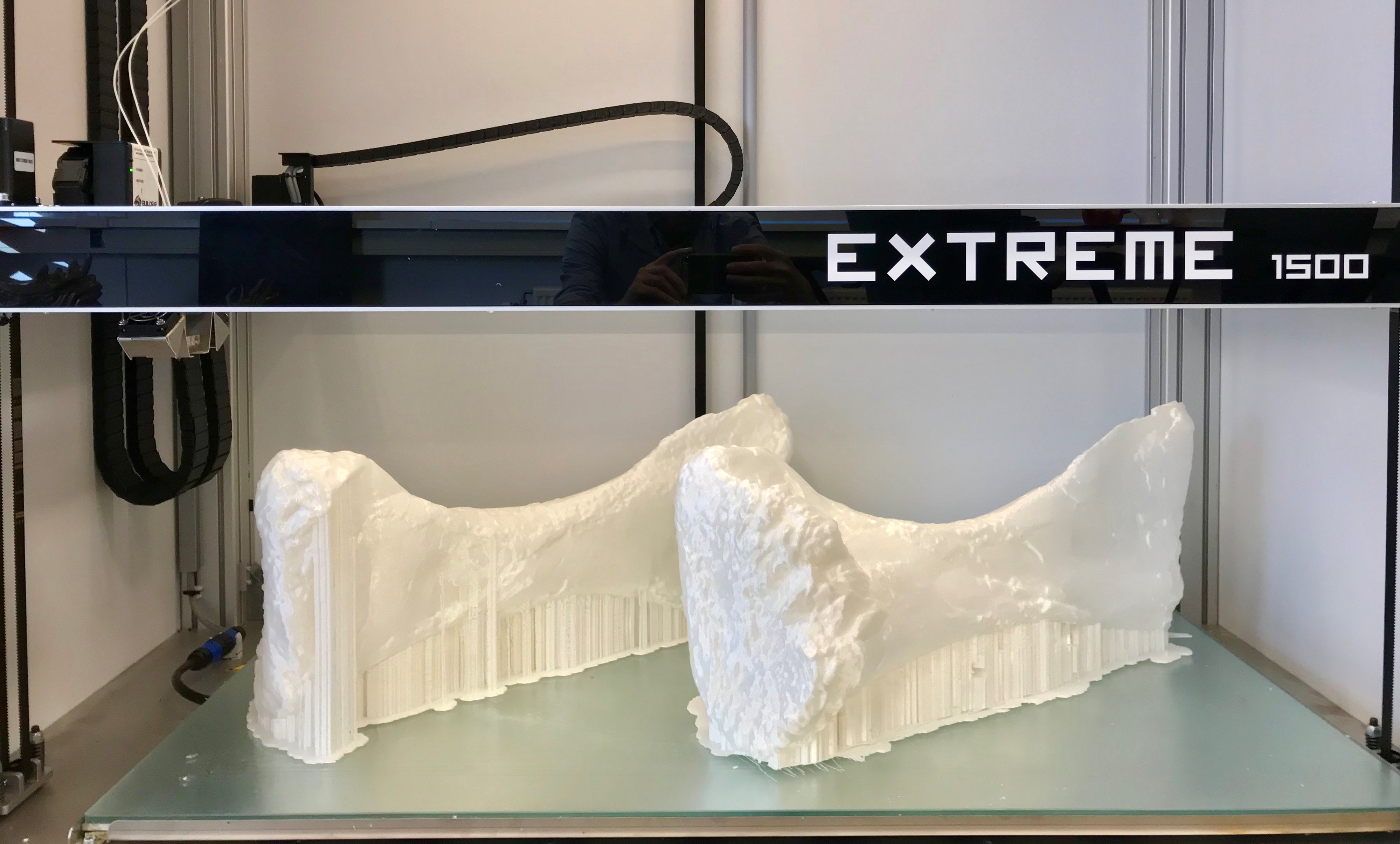

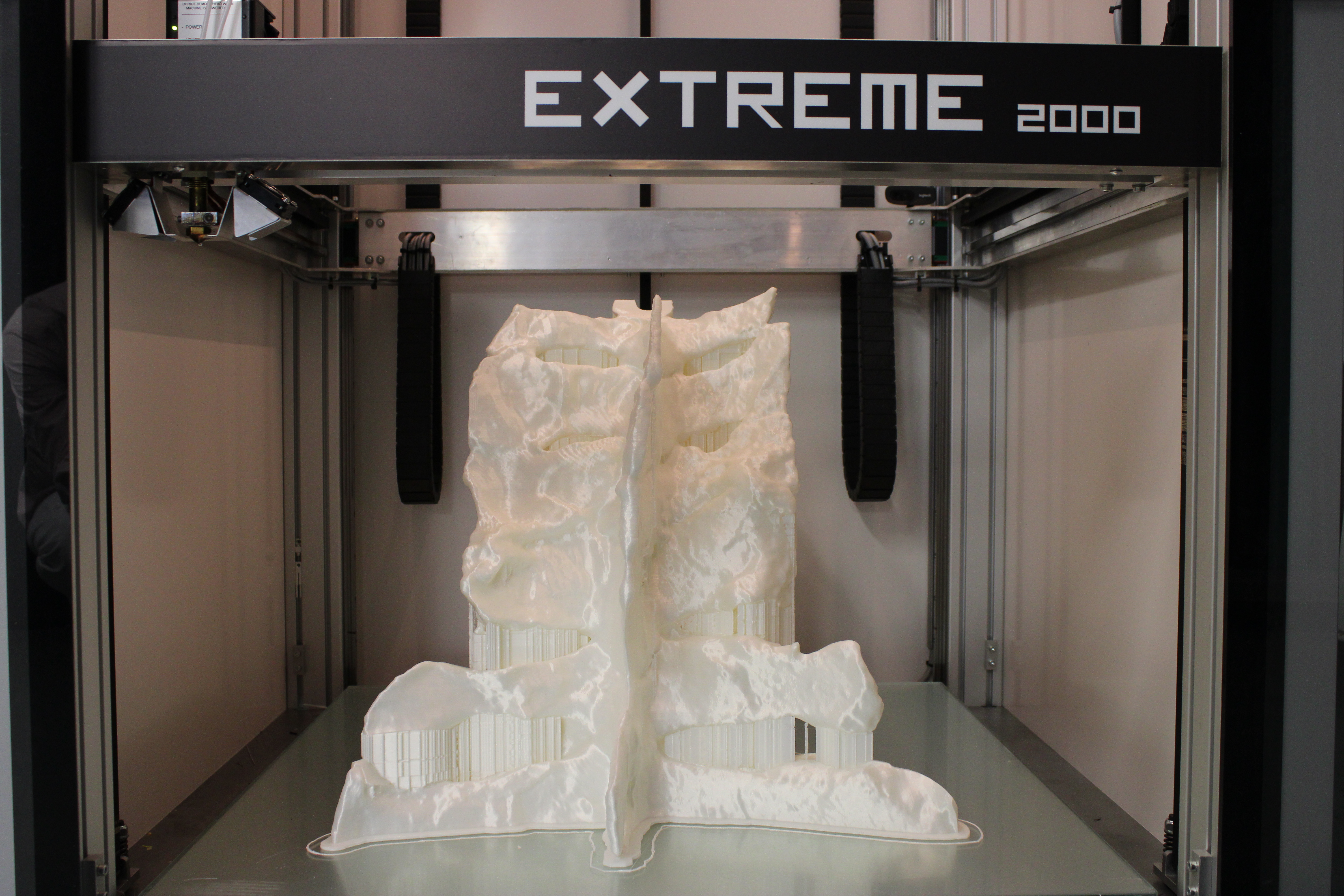

Dirk however represented a much larger project, with replacement bones measuring between 50 to 130 cm long. Naturalis therefore invested in the Builder Extreme 1500 PRO, a large scale FFF 3D printer featuring a 1100 x 500 x 820 mm sized print bed. “For a really big project such as Triceratops Dirk though, we had to look further, and that’s where the Builder Extreme came in focus,” added Schulp.

An upgrade to the standard Builder Extreme 1500 released in 2016, the PRO model features a print speed of up to 120 mm/s, and a layer height resolution of 0.1 to 0.9 mm. The system comes supplied with Simplify3D software and optimized FFF profiles for 0.4, 0.8 and 1.2 mm nozzles. Builder has also equipped the 3D printer with inbuilt transportation wheels, in order to improve its maneuverability in the workspace, and an air filter from BOFA.

3D printing the spare parts of a triceratops dinosaur

For the scientists to begin 3D printing the missing parts of Dirk, they needed to scan other triceratopses to gain an accurate representation of what they had to construct. “If we have, for example, a left bone and the right-side counterpart is missing, we can easily make a scan and a mirrored 3D print,” Schulp explains. Some of the reconstructed bone elements, particularly the vertebrae, however were sourced from scans of a Triceratops skeleton located at the Children’s Museum in Indianapolis, whose bones were considered complementary to Dirk’s. Naturalis also opted to scan and 3D print bones that were present but too fragile to be displayed like, for example, some of the ribs of Dirk which were not sufficiently preserved for mounting.

The Builder Extreme has now been 3D printing the missing bones continuously for the last two months, producing one hundred different parts. It was important for Naturalis to capture every visible minor detail of the bones in the 3D printed part. Significant focus has therefore been paid to the quality of the 3D print, utilizing support structures for the more complex shapes. After 3D printing and post processing, the bones were painted by hand. Due to the resemblance between the 3D printed bones and the actual ones, the replacement parts were painted a slightly lighter colour, allowing visitors to discern the real and artificial parts.

Completed in time for the museum launch in August, Dirk’s restoration has already prompted Naturalis to book the Builder Extreme 1500 PRO for an additional major project. The system is on display at the museum in order to inform the public how palaeontologists restore missing parts of dinosaur skeletons using 3D printing.

For more information on how Builder helped Naturalis resurrect the triceratops skeleton, click here.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the skeleton of Dirk the Triceratops on Display at Naturalis, featuring 3D printed bones. Photo via Naturalis.