BOFA International, a developer of fume and particle extraction technology, has announced the signing of a distribution partnership with France-based 3D printer supplier Atome3D.

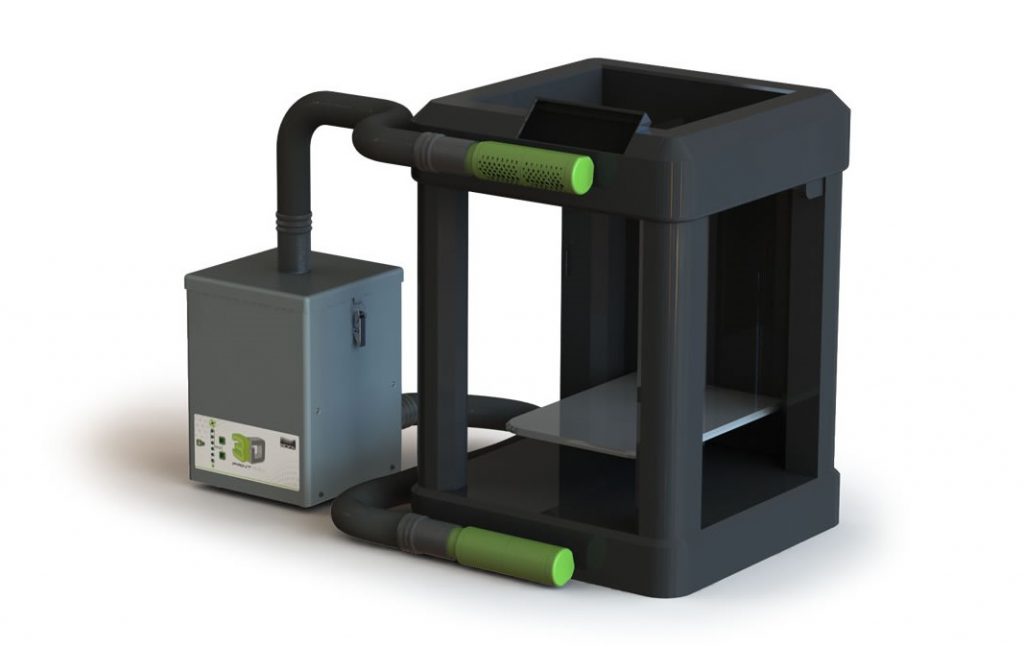

Going forward, Atome3D will offer BOFA’s entire portfolio of 3D PrintPRO air filtration products, including the 3D PrintPRO 2, 3, and 4. The devices are designed to integrate with third-party 3D printers to effectively capture any harmful fumes and particles emitted during the printing process.

Haydn Knight, BOFA’s Sales & Marketing Director, states, “We are delighted to announce our partnership with Atome3D.com, which reflects the success of the company’s commercial 3D print systems and the growing reputation of BOFA extraction technology in this marketplace.”

The hidden dangers of 3D printing

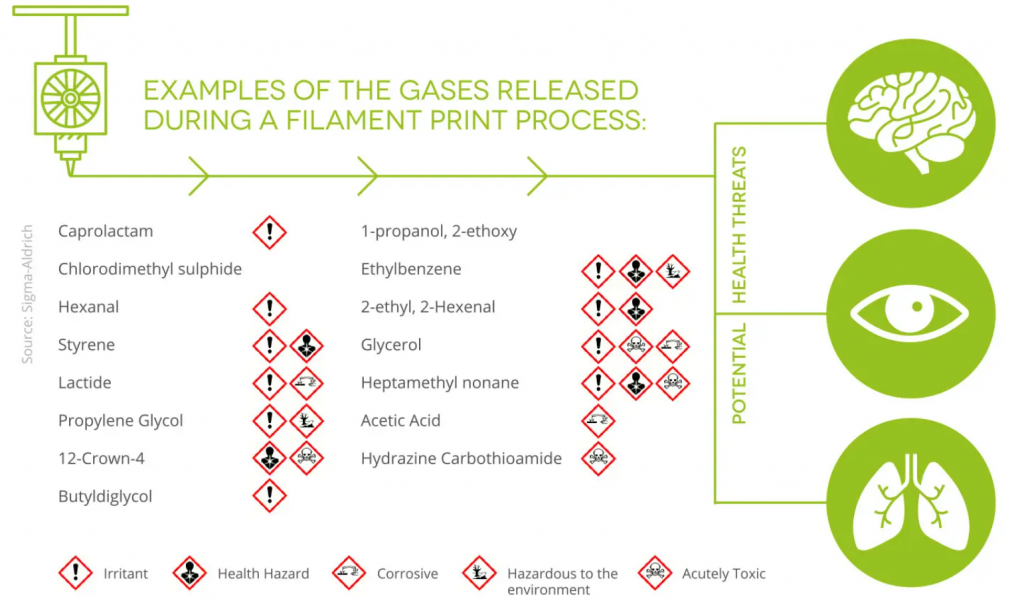

When operating a 3D printer, especially in human-occupied spaces like homes and offices, it’s essential to keep health and safety in mind. Since 3D printing often involves melting and sintering, one very real danger is the emission of airborne contaminants, which can come in all shapes, sizes, and smells.

Ultra-fine particles (UFPs) are often in the nanoparticle size range (smaller than 100 microns) but pose significant health hazards, while volatile organic compounds (VOCs) are characterized by their distinctly unpleasant odors.

The detrimental effects of both of these emissions are well documented, with organizations like the National Institute for Occupational Safety and Health (NIOSH) even publishing health and safety posters specifically targeted at 3D printing. Even short-term exposure can lead to a whole slew of health issues, including headaches, eye irritation, skin problems, respiratory issues, and damage to the central nervous system. This makes air filtration crucial in indoor working environments.

The study of emissions is an area of active research, and there are several factors that contribute to how harmful a 3D printing process actually is, such as material choice and the process parameters used in the build. Researchers from Seoul National University have previously investigated the effect of nozzle temperature on the emission rates of hazardous particles during FFF 3D printing, determining that emissions increased with temperature in all four tested polymers.

Elsewhere, scientists from the U.S. Environmental Protection Agency (EPA) have also studied VOC emissions during FFF 3D printing, this time looking at composites such as carbon fiber-reinforced ABS.

BOFA’s 3D PrintPRO range

BOFA International has modest roots, starting as a small family business back in 1987. Since then, the company has grown to be a major provider of fume extraction and filtration systems, with offices in the UK, Germany, and the USA. The company also exports to over 120 countries around the world, serving all manner of industries such as electronics, mechanical engineering, dental, pharmaceuticals, and 3D printing.

The company’s 3D PrintPRO range is designed specifically for additive manufacturing systems, and works with almost all commonly used 3D printing technologies. This includes FFF, SLA, material jetting, and powder bed fusion.

The compact units all offer active fume extraction functionality with optional speed controls, as well as mini pleat design HEPA filters. The HEPA filters are tested and certified to a minimum efficiency of 99.997% for particles as small as 0.3 microns, and 95% down to 0.1 microns.

Knight concludes, “Our relationship with Atome3D.com will help safeguard users by removing any potentially harmful airborne contaminants while at the same time optimizing productivity by preventing any build-up of material on high-value components. We look forward to a very positive future working together.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D PrintPRO 3. Image via BOFA International.