Aerospace manufacturer Boeing has unveiled a new high-throughput small satellite production and test facility with the aim of expediting cycle times with additive manufacturing.

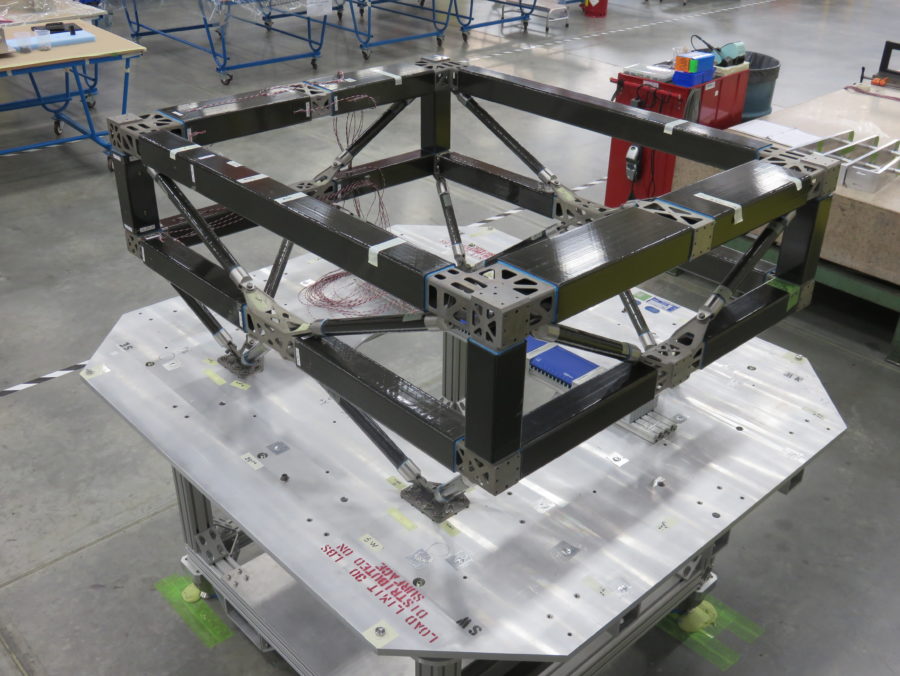

Spanning one million square feet, the facility is housed within the world’s largest satellite factory in El Segundo and will be powered by Boeing’s subsidiary Millennium Space Systems. In order to increase the rapid delivery timelines for small satellites, the facility will 3D print entire space-qualified satellite buses and is expected to be fully operational in late 2022.

“Boeing and Millenium are bringing together Boeing’s production expertise, domain knowledge, and manufacturing capacity with Millenium’s agility and rapid prototyping,” said Jim Chilton, Senior Vice President of Boeing Space and Launch.

“We’re scaling and growing to fulfill our customers’ vision for multi-orbit constellations with demand across markets and mission sets.”

3D printing space-ready parts

Boeing unveiled its plans to 3D print satellites back in 2017, and in the time since has launched its SES-15 satellite incorporating over 50 3D printing components.

More recently, the aerospace manufacturer has partnered with Titomic, the firm behind the Titomic Kinetic Fusion (TKF) 3D printing process, to investigate the use of sustainable titanium powders for additively manufacturing parts for space systems. Boeing will provide its design and engineering expertise to enable Titomic to demonstrate its TKF process for the production of space parts.

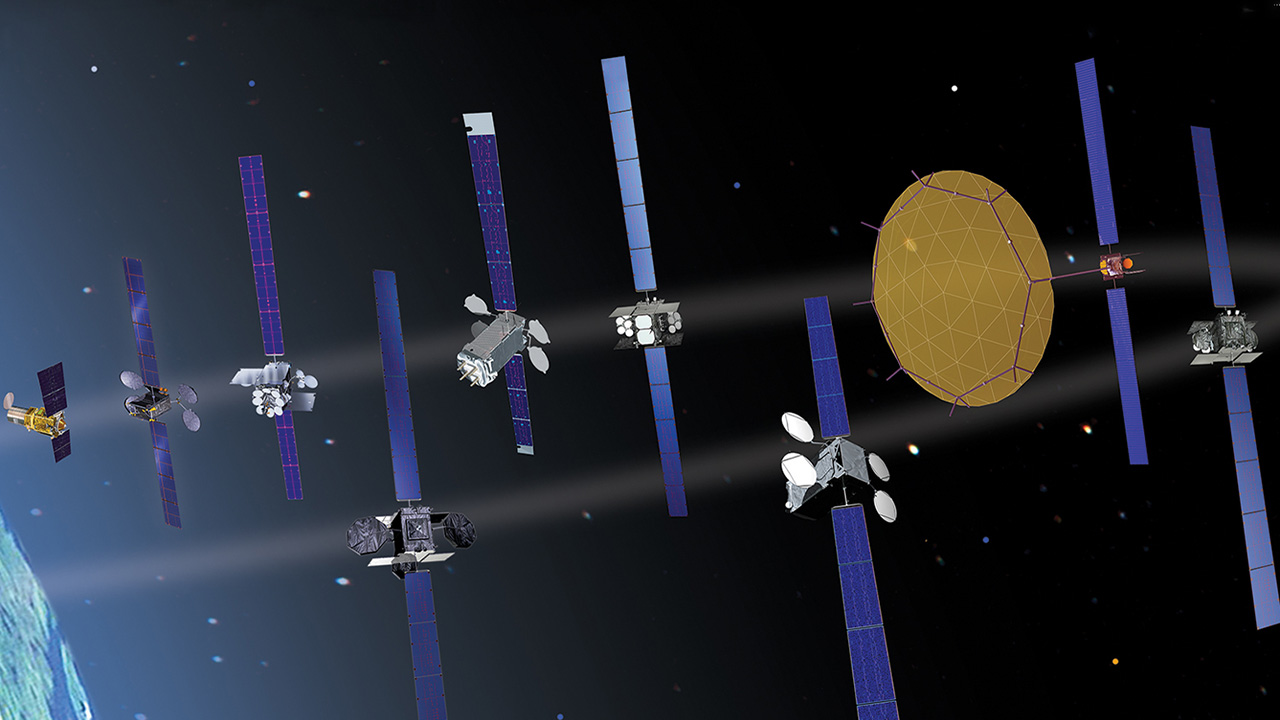

Boeing has also begun using 3D printing to ramp up its production of a Wideband Global SATCOM satellite for the US Space Force as part of a $605 million contract. The firm has introduced additive manufacturing into the satellite’s workflow to significantly reduce the lead time from 10 years to just five.

Offering faster satellite cycle times

Within the new satellite production facility, Boeing and Millenium Space Systems will leverage advanced additive manufacturing technologies to offer faster cycle times to customers.

The production line incorporates model-based systems engineering, digital design engineering, and design for manufacturability to enable the production of small satellites for different security levels on the same assembly line.

“Understanding security protocols and how to build secure systems is critical to national security space, and this is an area where Millenium and Boeing excel,” said Jason Kim, CEO of Millenium Space Systems. “We’re excited to leverage this impressive capability to support our customers’ critical missions.”

The facility will also provide environmental test capabilities specifically tailored to small satellites, including those that have qualified iconic spacecraft in the past, such as the first vehicle to make a fully controlled soft landing on the moon.

“Our customers need satellites on-orbit faster than ever,” said Chilton. “Much like an airplane or auto production line, we’re employing lean production principles and advanced manufacturing techniques to accelerate delivery and pass on cost savings to our customers.”

Initial operating capability for the facility took place back in September, with full operational capability expected in late 2022.

“Millenium’s culture is rooted in creating innovative ways to revolutionize space,” added Kim. “We’re bringing that culture into our facilities, rapidly building large constellations of high-performance small satellites, taking advantage of a footprint that’s larger than two professional hockey rinks.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows a render of what the WGS-11+ is expected to look like. Image via Boeing.