Blackstone Resources, a Swiss investment firm focused on battery technology, has announced that it expects to begin commercializing a new 3D printed sodium-ion battery design as early as 2025.

The firm’s own German R&D subsidiary, Blackstone Technology, will work with a consortium of academic and industrial partners to demonstrate its 3D printed solid-state batteries in a real world use-case within the next three years. Specifically, the 3D printed solid-state batteries will be installed on a Eurabus electric bus, validating their performance on the road.

To fund the commercialization, Blackstone will invest €32 million in a pilot facility at its manufacturing plant in Döbeln, Germany.

Blackstone’s consortium partners include the Zeiss Group’s Microscopy and Industrial Metrology arms, which will contribute with expertise in their respective fields. Additionally, the Institute for Particle Technology at the Technical University of Braunschweig and three Fraunhofer Institutes – IFAM, IKTS, and IST – will help with process validation, process development, recycling, and safety.

Moving towards sodium-ion technology

According to Blackstone, modern-day liquid electrolyte battery production lines tend to be very specialized, allowing firms to manufacture only one type of battery at a time. The process is also a very energy-intensive and costly one, and uses dangerous solvents as raw materials for electrodes.

On the other hand, Blackstone’s ‘Thick Layer Technology’ 3D printing approach is intended to be much more flexible and cost-effective, enabling the production of a wider range of cell formats while using environmentally friendly materials. Owing to the versatile nature of the 3D printing process, Blackstone states that it can even tailor the size and shape of the cells to the customer’s requirements.

With the ultimate aim of tackling the electric vehicle market, Blackstone has focused largely on 3D printing lithium-ion batteries until now. The upcoming sodium-ion variants are expected to offer several advantages as the raw materials can be obtained much easier, at lower costs, in a more environmentally-friendly manner.

By 3D printing these solid-state batteries, Blackstone claims that it can increase energy density while improving safety when compared to traditionally manufactured counterparts. In fact, the firm believes that the first batch of its sodium batteries will be able to replace established energy storage systems in a variety of industry sectors.

“Sodium-ion technology represents the next generation of our already market-leading 3D printed batteries,” said Holger Gritzka, CEO of Blackstone Technology. “We are pleased to once again make an innovative and viable contribution to clean energy and the carbon-neutral transportation of the future.”

Commercialization as early as 2025

If all goes according to plan, the company will have already tested its 3D printed sodium-ion batteries in an electric bus by the end of 2025. The long-term goal is to scale this printing up to series production, whereby complete solid-state battery cells will be manufactured at high speeds in a variety of shapes and performances – all in one 3D printing facility.

Gritzka adds, “We can seamlessly transfer our current experience in printing lithium-ion battery electrodes to the production of sodium-ion cells. This lays the foundation for the subsequent series production of solid-state sodium-ion batteries in 2025.”

To reach this goal, Blackstone is already looking into upscaling the processing of sodium-based solid-state electrolytes on a ton scale. This effort is being funded by the German Federal Ministry of Economics and Climate Protection as part of its battery cell manufacturing support program. Blackstone expects to receive a total of up to €24.1 million from the ministry, subject to the grant being approved.

The 3D printing of energy storage devices is very much a niche field, with much of the work still in its early stages. Last year, researchers at the Swiss Federal Laboratories for Materials Science and Technology (EMPA) used 3D printing to create a sustainable new class of supercapacitor. The fully-3D printed battery, composed of a flexible cellulose and glycerol substrate, patterned with a conductive carbon and graphite-laden ink, is able to withstand thousands of charging cycles while maintaining its capacity.

Elsewhere, Sakuu Corporation (formerly KeraCel), a specialist in 3D printed energy storage devices, recently reached a new milestone in the development of its lithium metal battery, achieving a benchmark energy density of 800 Wh/L. According to the firm, the achievement is a significant step forwards on its roadmap to fully 3D printed solid-state batteries capable of greater than 1,200 Wh/L by 2023.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

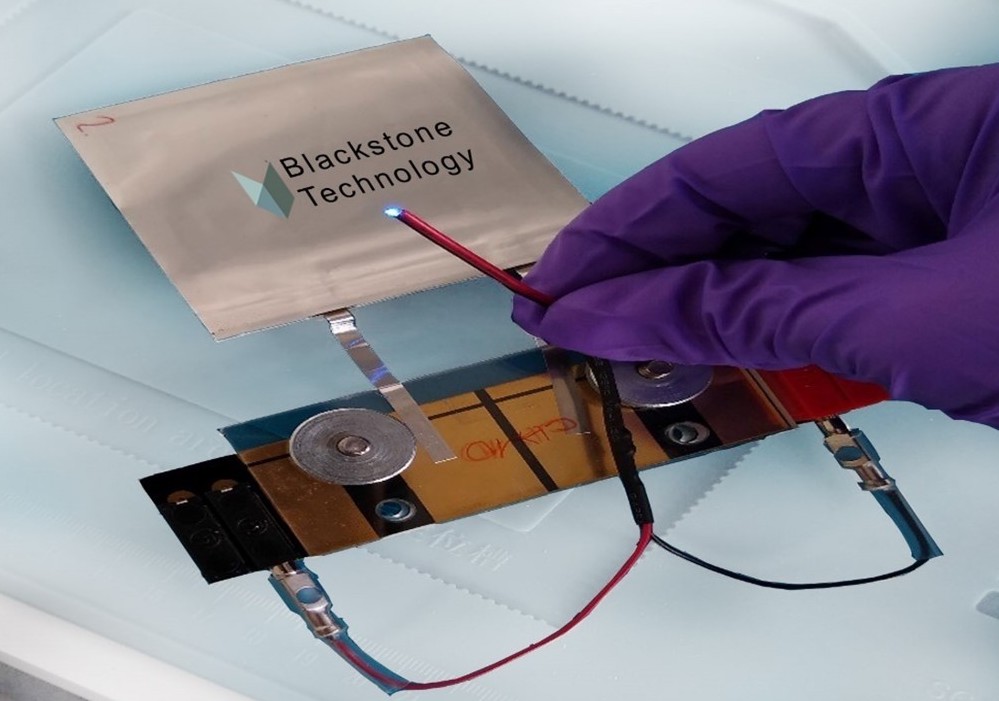

Featured image shows a 5×5 cm-squared pouch cell with luminous LED, 3D printed using Blackstone’s technology. Photo via Blackstone.