BCN3D Technologies, a Spanish 3D printer manufacturer, and the Istituto Europeo di Design (IED) Barcelona have partnered to accelerate creativity for its students.

Based in Castelldefels, IED Barcelona is an international network of 11 universities specializing in design, fashion, visual communication and management. The institute has implemented BCN3D 3D printers for the manufacture of prototypes and functional parts for projects.

“For BCN3D to be able to offer our 3D printers to universities and specialized educational centers, such as IED, means entering a strategic sector with which we want to continue working closely [with],” said Xavier Martínez Faneca, CEO of BCN3D.

“Our philosophy as a technology firm that designs and manufactures its own 3D printers in Barcelona is focused on helping universities and educational and creativity centers to correctly implement 3D printing and go hand in hand with strategic partners, as is the case of IED.”

Accelerating the creative process

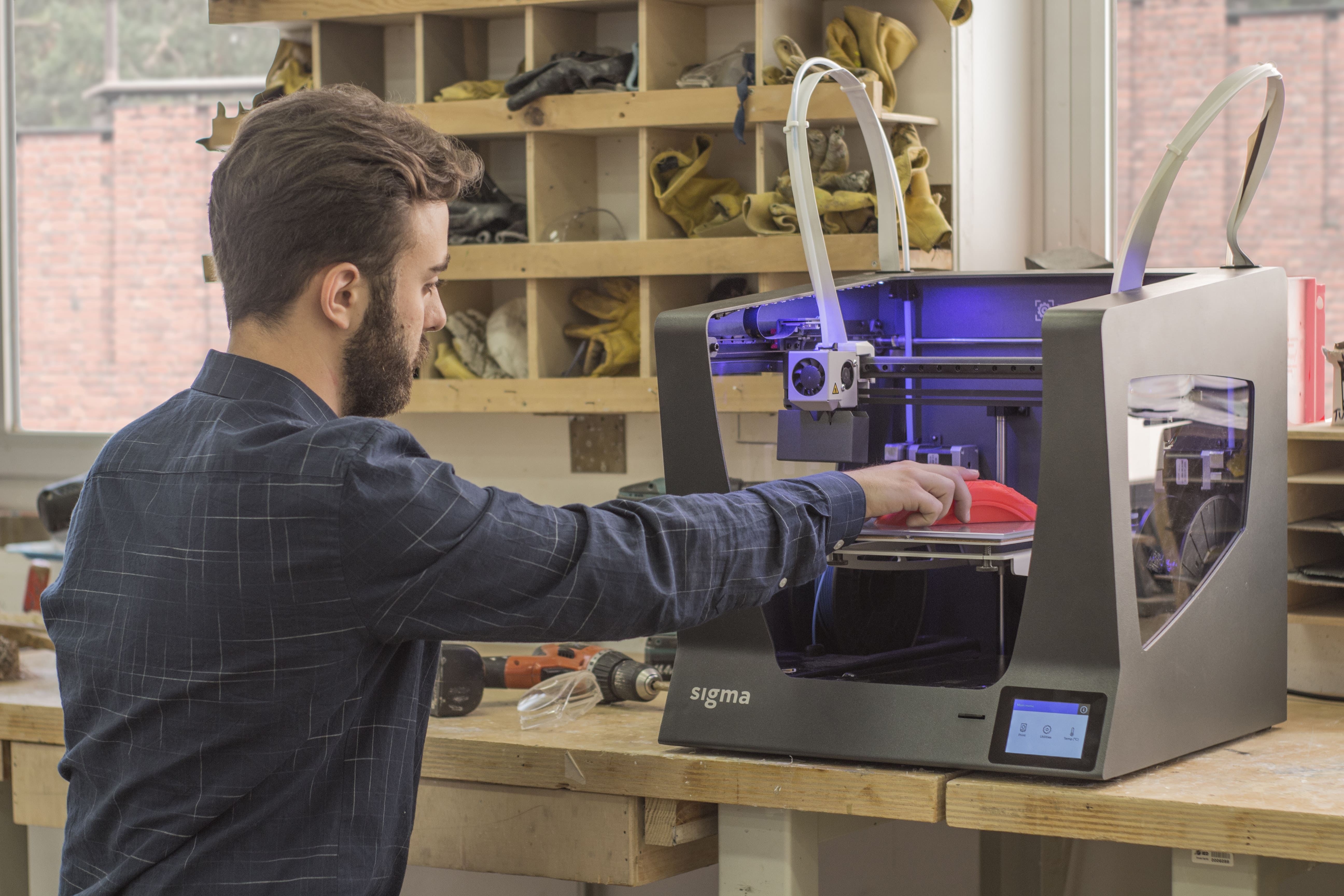

In 2017, IED Barcelona incorporated additive manufacturing to provide students with technology to conceptualize their project ideas. This has led to the development of automobile concepts for 2035 cities, fashion accessories, and models for future hospital environments. As a result, its Maker Lab has adopted BCN3D’s Sigma and Sigmax 3D printers.

Raffaella Perrone, development director of the Design area of IED Barcelona, explained, “Rapid prototyping takes a lot of importance, especially in

the discipline design. Thanks to the new technologies that we have within

reach, the creation of rapid prototypes allow [us] to accelerate the creative

processes.”

IDEX technology

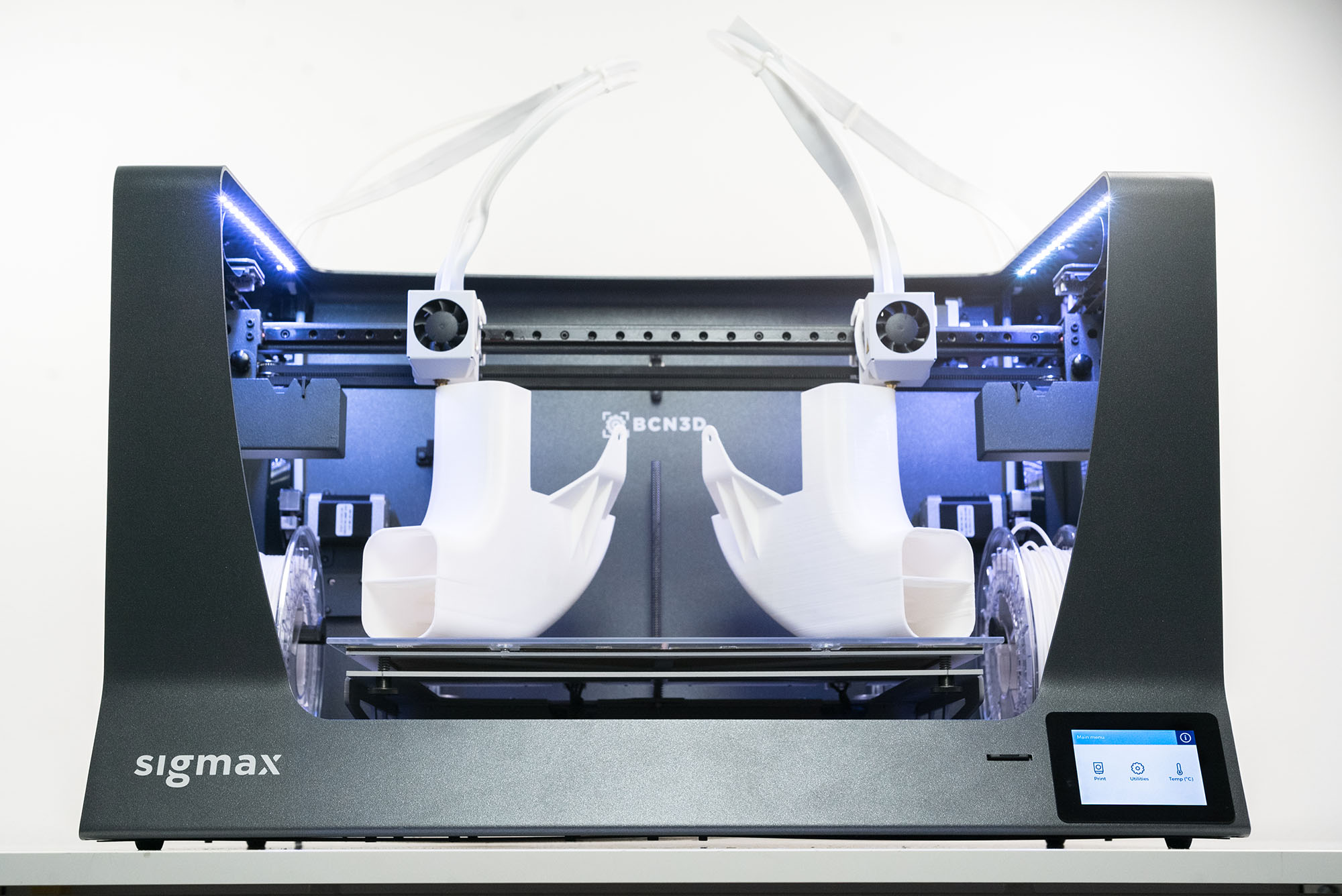

According to IDEC students, Independent Dual Extruder (IDEX) technology, integrated into BCN3D 3D printers, has particularly aided in the reduction of model creation. This has been useful in meeting academic deadlines. Perrone added, “Students, during the design process, can quickly validate and materialize ideas through 3D printed models.”

The IDEX architecture enables 2 different materials or colors to be printed while one toolhead remains parked, preventing the dripping of molten plastic onto the part. Additionally, the IDEX architecture allows symmetrical printing with both toolheads simultaneously for double the production capacity.

The 3D printers at IDEC Barcelona have been said to enhance the creativity of more than 1400 students.

You can keep up with additive manufacturing news by subscribing to the 3D Printing Industry newsletter, following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a student at IED Barcelona uses 3D printing. Photo via BCN3D Technologies.