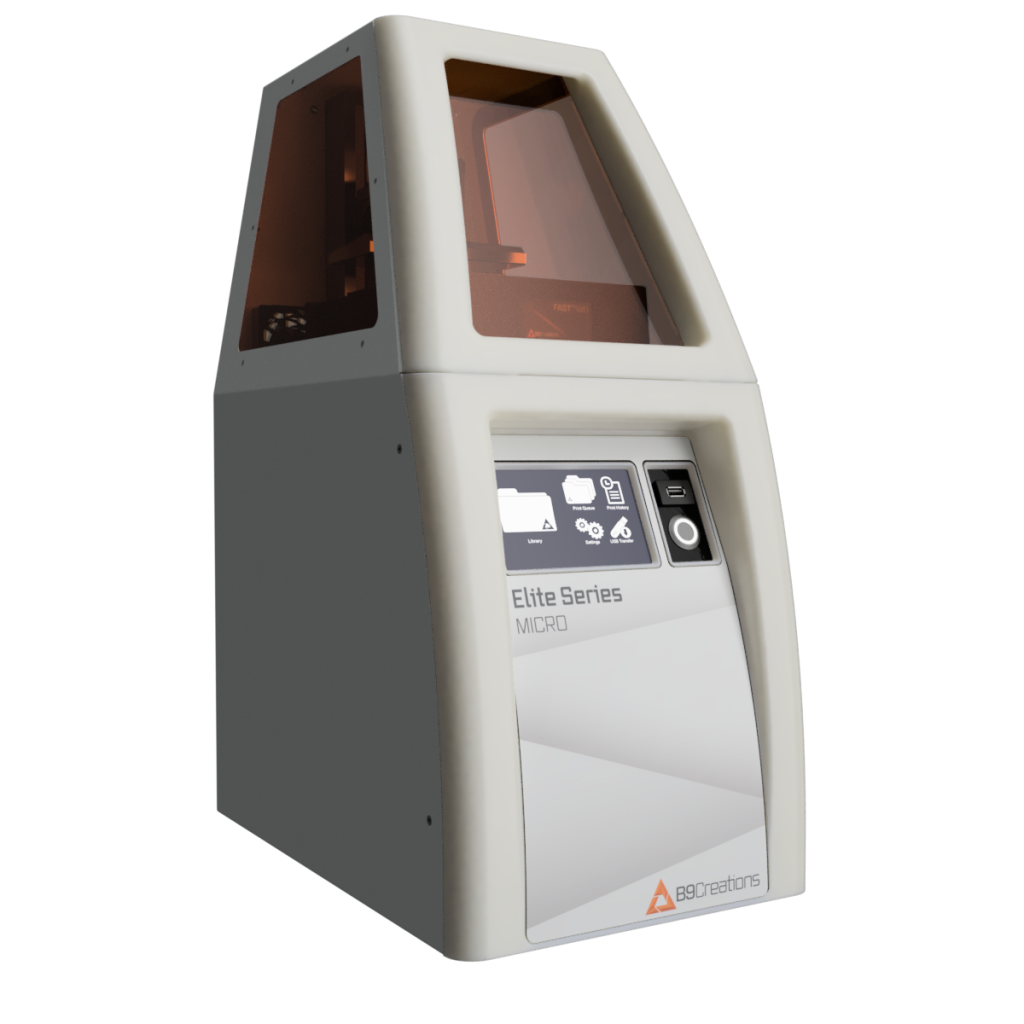

South Dakota-based manufacturer of resin 3D printers B9Creations has launched its ultra-precision B9 Elite Micro 3D printer.

The system produces micro holes and relatively thin wall thicknesses for parts that exceed the limits of feature size functionalities at one-fourth the price of high-end, enhanced micro 3D printers. The Elite Micro from B9Creations allows users to 3D print structures which would be impossible to produce by any other means, “reshaping” additive’s place in the manufacturing ecosystem and “boosting a revolutionary transformation” encompassing a broad range of medical and industrial applications, claims the company.

“There are so many parts I see a machine like this finally making possible to create, that otherwise might have been out of reach for many due to system costs. This machine brings respectable precision, on a reliable platform already established for its ease of use, along with decent build rates – and you did it for a reasonable price in relation to its capabilities,” said Senior Principal Design Technician at the largest medical device manufacturer in the U.S.

Characteristics of the B9 Elite Micro 3D printer platform

B9Creations believes that the B9 Elite Micro pushes 3D printing forward into the modern era. With ultra-high resolution, accuracy, precision, and repeatability, it pushes the limits of feature size capabilities at the scale, with tolerances that meet or exceed micro injection molded parts. It comes with a native pixel size of 20 microns and micro features like holes of 100 microns, allowing it to produce the most difficult micro components at production quality.

The B9 Elite Micro prints in 15 minutes out of the box with factory startup support and never needs to be calibrated. The system, according to the company, offers advanced print preparation, control, and monitoring software. With automated sanitizing and curing post-processing units, the system offers a streamlined workflow. Users can use B9Creations resins or third-party materials directly or have B9Creations create a custom resin.

According to the company, B9 Elite Micro’s annual service kit includes on-site coaching and implementation, a loyal customer success expert, a hot swap program, and more. Regulatory standards, build volume, resolution and precision, materials, software, regulatory requirements, and implementation, along with the B9 expert team are all customizable.

Companies manufacturing micro 3D printing technologies to advance the AM sector

Previously, microfabrication start-up Horizon Microtechnologies debuted a novel microscale 3D printing technology at Formnext 2022. The company’s template-based micro-additive manufacturing, or ‘micro-AM,’ process produces conductive parts with micrometer-level precision. After bringing its technology into the market, the company stated that for the first time, it could help bring higher manufacturing flexibility to the manufacturing of electrodes, electrical contact pins, ESD-safe parts, microfluidic devices, MEMS, and optics packaging.

“Template-based 3D microfabrication is effectively a mechanism to exploit the usefulness of polymer micro-AM produced 3D microstructures (the template) for hitherto unserved areas of industry. This is a real game-changer,” said the firm’s CEO Andreas Frölich. “Horizon Microtechnologies bridges the gap between micro-AM and parts with enhanced functionality through the use of proprietary post-build processes.”

Furthermore, desktop 3D printer manufacturer Anycubic collaborated with display panel specialist Jade Bird Display (JBD) to create the J1 MicroLED 3D printer, a consumer-grade MicroLED 3D printer. The machine, codenamed ‘J1,’ has a JBD UV MicroLED display and a customizable 0.3CC light engine, allowing it to print components with details as small as 10m in an ergonomic manner. As a result, the system, which was set to make its debut at TCT Asia in August, was marketed as the first of its kind, offering “precision, low power consumption, and a long lifetime at a competitive rate.”

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows B9 Elite-Micro 3D printer. Image via B9Creations.