Launching a Kickstarter Campaign on September 18th, two days before the World’s Maker Faire began, Wayne Qiu, CEO of 3DMakerworld hopes to receive $30,000 in funding from backers for the new Artifiex 2 and Artifex Duo 3D Printers. Offered both as a kit and pre-assembled, backers can get their hands on the Artifex 2 and Artifex Duo right now by pledging $1,495 and $1,545 respectively.

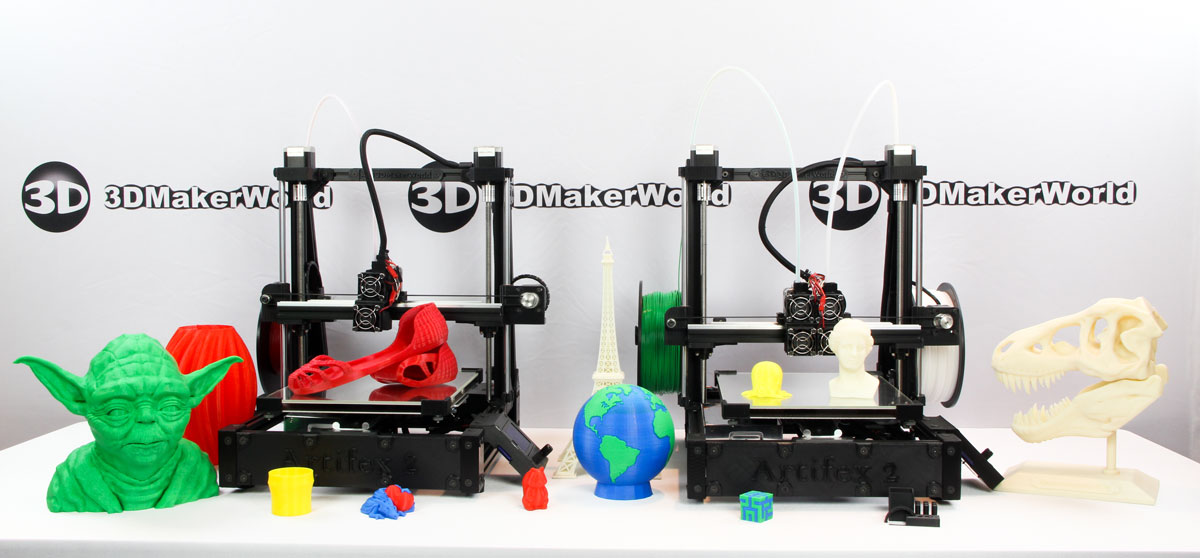

The Artifex 2 and Artifex Duo received their share of attention at the Maker Faire, showing off their high layer resolution (50 microns), quickness (150 mm/sec) and large build volumes (642 cubic inches and 952 cubic inches). Expanding the pallet of materials is a solid move in the right direction. Designing a printer that will produce reliable flexible filament prints consistently is a huge plus. By completely redesigning their filament drive to enable smooth and effective extrusion of flexible filaments (without any tool changing) as well as PLA, ABS, HIPS and PVA, the Artifex 2 printers are directly addressing the call for standardizing a wider array of 3D printing materials for use in affordable desktop printers. Right now, the Artifex 2 and Duo are less expensive than another great multi-material desktop printer, the Lulzbot.

What software does it use? The Artifex 2 and Artifex 2 Duo are compatible with Repetier Host, which brings up an intersecting synergy between two different areas of the 3D printing industry.

With the emergence of a number of user-friendly 3D printing host software companies (PrintToPeer, Octoprint, 3D Control Systems, AstroPrint et al), the RepRap community is arguably more empowered to innovate and create more capable, dynamic 3D printers without worrying about software hindering inexperienced users or beginners from taking an interest. The Artifex 2 printers are a perfect example. Building upon the design of the highly revered MendelMax 2, both the Artifex 2 and Artifex Duo3D printers will make it easy for “universal 3D printing OS” companies to modify existing plug-ins, and bring them into the fold.

It’s important to find common threads in the enormous world of 3D printing, which is why walking around the 3D Printing Village at Maker Faire is so interesting. If you do Google-fu all day, bouncing from one company site to another, everything looks pristine and perfect. All of the specs are there, the machines look their best, and there is no hint of anything going awry. Walking around the sunny fairgrounds in Queens, however, you can feel that everything is on the line. These companies are trying their best to get out there and show off their wares. Anything can go wrong. Sometimes, it’s unavoidable. As I stopped at the Artifex booth, the quality of the printers and objects impressed me as much as the sparks of excitement being passed back and forth between Wayne and the crowd.

I spoke with Wayne after the Faire ended, and he answered a few follow-up questions about his team’s recent experience at the World’s Maker Faire, as well as his company and his new series of 3D printers.

3DPI: What was your favorite experience at Maker Faire?

Wayne: Our favorite experience at the Maker Faire was to have the chance to meet so many visitors: makers, educators, students, professionals, parents and kids. It was such an enjoyable experience to chat with them about their projects and needs, introduce our Artifex 2 3D printers, answer their questions, and hear their ideas and suggestions.

3DPI: What are some of the biggest challenges you face as a company?

W: Consumer 3D printing is a fast-growing field. With constantly introduced new materials and applications, it’s very challenging (and exciting as well) to quickly develop new products to enable the adaptation of new materials and technologies.

3DPI: What is your favorite application of the Artifex 2?

W: Flexible material printing. This can really open the window to a wide range of new applications: fashion design (e.g., shoe design), health care (e.g., personalized insoles), industrial prototyping (e.g., iphone case), etc.. In conjunction with dual-head extrusion capability, the flexible material extrusion capability of Artifex 2 can create lots of new possibilities.