Industrial 3D printer manufacturer AON3D has released the AON-M2 3D printer. A next generation of the successful AON-M system, the AON-M2 is a large format, high temperature 3D printer made to produce engineering grade end-use parts for automotive, aerospace and healthcare industries.

Positioned well as a middle market alternative to Stratasys 3D printers, the AON-M2 has a highly competitive price point for professional quality 3D printers, and can be bought at aon3d.com.

“The AON-M2 was designed from the ground up for professional users – especially those that need to make functional parts,” comments Kevin Han, the company’s CEO. “The printer is compatible with the highest-strength plastics available for 3D printing – like PEEK, and has a large build area to handle larger runs of parts.”

AON 3D printing for end-use production

The AON-M2 has been developed as part of AON3D’s vision to make professional-quality 3D printing more accessible to businesses expanding and adapting their production capabilities. As observed by Randeep Singh, co-founder of AON3D, the current market trend is moving towards 3D printing for end use production.

“The fact that high-end materials are possible to work with is huge – it’s the primary driver opening up end-use markets,” writes Singh.

“We’re seeing a trend of people obtaining an AM solution, and realizing how much more powerful it can be once they learn how to use it. As the AM solutions become more and more user friendly, we predict this trend to continue.”

3D print virtually any polymer

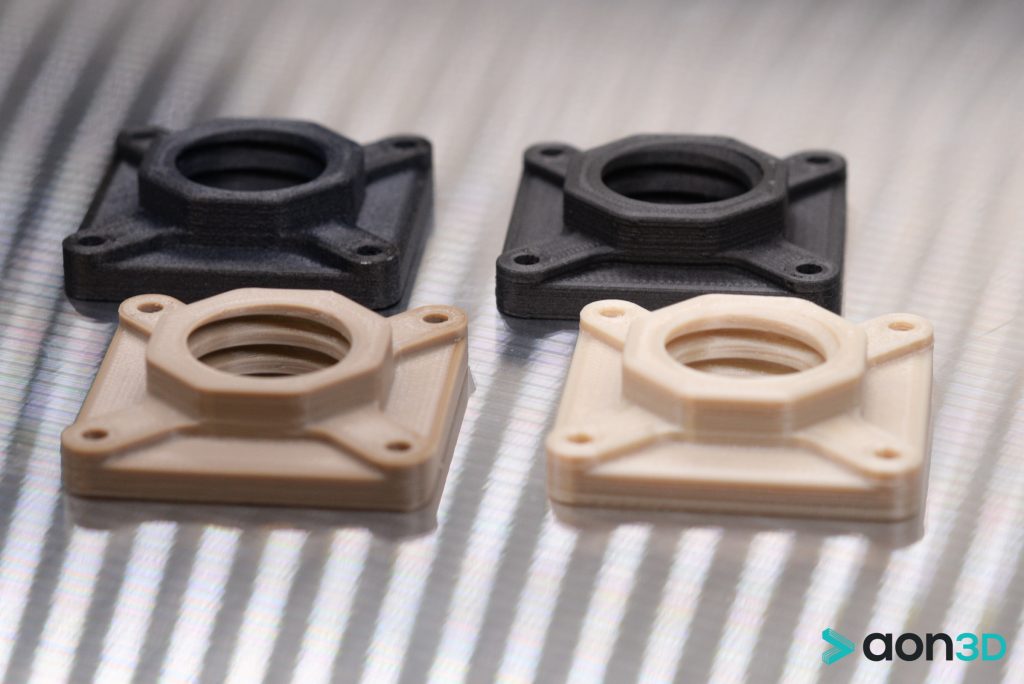

AON3D is committed to the open materials system, allowing users to use any known 1.75 mm spool, or develop their own feedstock for fused filament fabrication (FFF). With dual extruders, the AON-M2 is a multi material 3D printer, enabling simultaneous extrusion of a primary material and soluble/breakaway supports.

PEEK, PEI (ULTEM®), Nylon and Polycarbonate (PC), serve as examples for commodity and specialty plastics 3D printable by the AON-M2. To serve the demand for more performance materials AON3D is also working with developers, including Essentium Materials, in each class to produce the best possible filaments for its 3D printers.

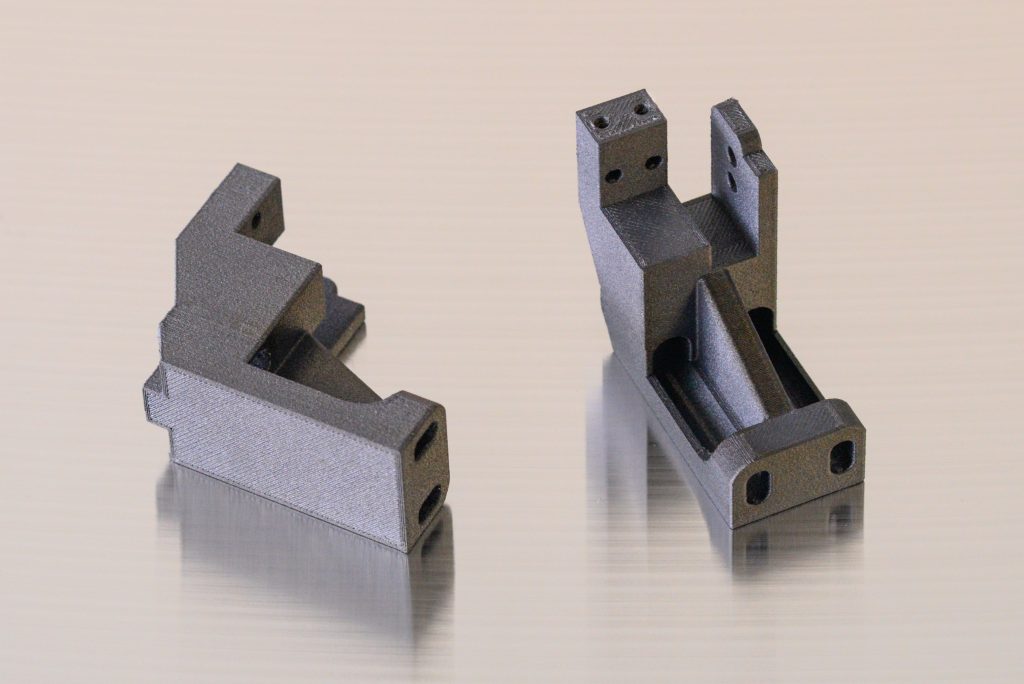

A replacement for metal components

The maximum temperature achievable in the AON-M2 hot end is above 500°C and the bed reaches beyond 200°C. The build chamber, with best-in class specifications only surpassed by Stratasys Fortus systems, can sustain a temperature of over 120°C.

The ability to 3D print with these temperatures maximizes interlayer bonding, and reduces the tendency for high-end polymers like PEEK and Ultem to warp & crack. The end result is stronger, more accurate parts.

In many cases, from tooling, jigs and fixtures to replacement components, advanced thermoplastics are strong enough to replace metal. In addition, 3D printed polymers benefit from a low cost-per part, material lightness, and high chemical resistance. In fact, one supported polymer, PPS Poly(p-phenylene sulfide) is invulnerable to any known chemical at temperatures under 200°C.

For enhanced industrial 3D printing the AON-M2 is available to buy now directly from AON3D.

Full technical Specifications

Printing Technology: Fused Filament Fabrication (FFF)

Build Volume: “454 x 454 x 640 mm (18 x 18 x 25 in”)

Max Speed: 500 mm/s

Z Layer Height: ≥ 0.05 mm to 0.5mm

Max. Temperatures

Hot End: 500°C+

Heated Bed: 200°C+

Build Chamber: 120°C+

Nozzle Sizes (mm): Hardened Steel: 0.25, 0.3, 0.4, 0.6 (default), 0.8, 1.0, 1.2

Filament Size (mm): 1.75

Materials: PEEK, PEI (ULTEM®), PPSU, PSU, Nylon, PC, TPU, TPE, PETs, HIPS, PVA, ASA, ABS, etc. Carbon or other fiber filled variants of the above. Various soluble and breakaway support materials.

Software & Connectivity

Slicer: Simplify3D License with two floating seats

Control Interface: LCD control screen. WiFi enabled. Ethernet. USB.

Mechanical

Build Plate: ALCA 5 precision aluminum. Hot-swappable

Toolheads: Dual, fully independent

Drivetrain

XY Resolution XY: 0.025 mm (theoretical)

Z: 0.001 mm (theoretical)

Electrical

Supply Voltage: 208-240VAC, 20A, 50/60Hz, single phase

Outlet: NEMA 6-20

Physical

Weight: 265 kg / 868 lbs

Height: 1450 mm / 57in,

Width: 955mm / 37.6in

Depth: 965mm / 38in – Delivered depth is 835mm / 32.9in; without door 805mm/31.7in

Environment

Max Room Temp: 28°C

Humidity: < 80%

For more 3D printing news and the latest hardware releases subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Vote for your technologies of the year and more in the 2018 3D Printing Industry Awards. To be in with a chance of attending this year’s event, winning a 3D printer, and having your design 3D printed by Protolabs, enter the 3D Printing Industry Awards trophy design competition.

Looking for you next career move or new talent? You can search and post over at 3D Printing Industry Jobs now.

Featured image shows the AON-M2 3D printer in the workshop. Photo via AON3D