Australian large-format 3D printer manufacturer AML3D has sold an ARCEMY Wire Arc Additive Manufacturing (WAAM) metal 3D printing system to Curtin University.

The sale, worth AUD $1 million, is in line with AML3D’s goal of generating more revenue from ARCEMY system sales. The addition of this ARCEMY system will enhance Curtin’s current small-scale R&D capabilities in its Additive Manufacturing Microfactory Facility.

“AML3D is delighted to be able to support Curtin University in expanding its wire additive manufacturing capabilities with the purchase of an enterprise-level ARCEMY System. This sale represents AML3D delivering against its strategic objectives and is an excellent opportunity to partner with Curtin to expand the applications for our Wire Additive Manufacturing technology in Australia and globally,” said AML3D Interim CEO Sean Ebert.

Advancing 3D Wire Arc Additive Manufacturing in Australia

The sale contributes to the advancement of 3D wire additive manufacturing in prominent educational and research institutions, which will be instrumental in enhancing Australia’s defense manufacturing capabilities. Furthermore, the Curtin Microfactory will serve as an R&D platform for AML3D, allowing it to showcase the capabilities of ARCEMY to potential customers in industries such as Mining, Agriculture, Oil & Gas, and Defense Maritime in Western Australia.

As part of the sale agreement, AML3D will offer three years of software licensing and technical support. The sales proceeds will be received in three installments, starting from the purchase order receipt and continuing until the delivery and installation of the newly purchased system.

Additionally, AML3D and Curtin University have partnered for a research program utilizing the ARCEMY system. AML3D will contribute AUD $100,000 annually for three years to support a Research Fellow and a Ph.D. candidate. The research performed under this collaboration will focus on new alloys and materials science, catering to the needs of defense customers using AML3D’s WAAM-proven technology through accreditations.

“We look forward to collaborating with Curtin on research that will enhance the capability of our ARCEMY systems for our customers, especially in defense and maritime. Over the longer term, this research program should help to position AML3D to benefit from an expected expansion of defense manufacturing that AUKUS and other demand signals will drive,” added Ebert.

WAAM: A versatile technology for large-format metal parts

Earlier this year, AML3D sold its industrial ARCEMY ‘X-Edition 6700’ WAAM metal 3D printing system, to enter the US market and support the US Navy‘s implementation of WAAM technology. According to the company, WAAM plays a crucial role in ramping up the supply of components to the US Navy’s submarine industrial base. The order for the ARCEMY system was placed by BlueForge Alliance, a US Department of Defense intermediary, with the aim of accelerating advanced manufacturing techniques throughout the US defense industrial base.

Cranfield University spin-out WAAM3D sold its RoboWAAM Advanced system to Aichi Sangyo, a Japanese metal processing solution provider. This marks the sixteenth deposition system sold by WAAM3D globally. The RoboWAAM is a large-format metal 3D printer with a massive build volume of 2 x 2 x 2 m. It is equipped with advanced sensing hardware and a robotic arm, making it suitable for various industries including aerospace, defense, and energy. The system can process a wide range of wire-based materials and is used for both component manufacturing and metal part repairs.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

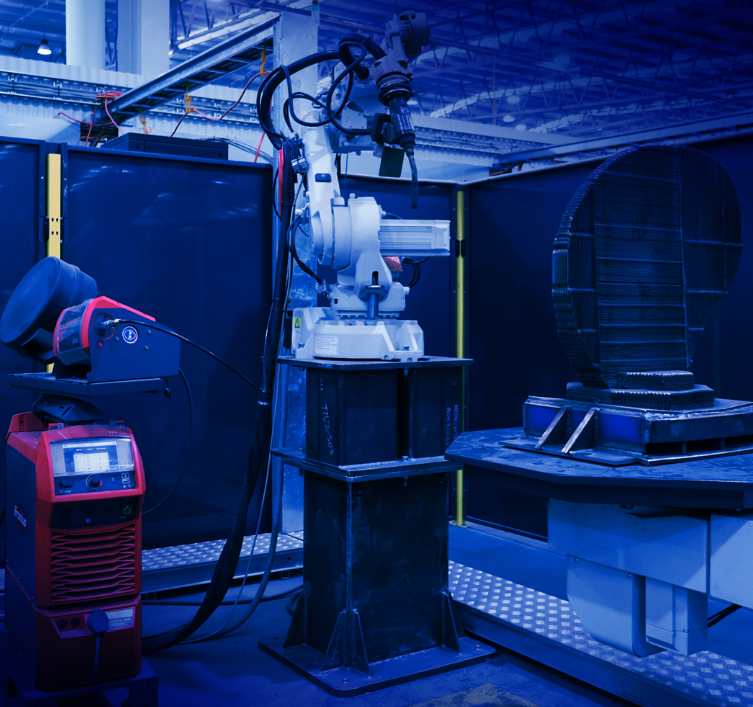

Featured image shows a typical ARCEMY metal 3D printing system. Image via AML3D.