Funding raised by Massachusetts based material manufacturer Amastan Technologies is to be used to cement the company’s capabilities in additive manufacturing. Announcing the closing of $11 million in Series B-2 capital on May 21, 2019, the company confirmed plans to invest in a new additive manufacturing metal powders facility in Pennsylvania, as well as intentions to expand existing production capacity. AL Solutions, Inc., a titanium materials production specialist, has also been acquired by Amastan and its expertise will be used as part of this strategy.

According to Aaron Bent, CEO of Amastan Technologies, “This additional infusion of capital, along with the acquisition of AL Solutions accelerates Amastan into full production mode and creates a clear and unique pathway for us to manufacture premium metal powders that are derived from sustainable sources.”

Forming Amastan Additive

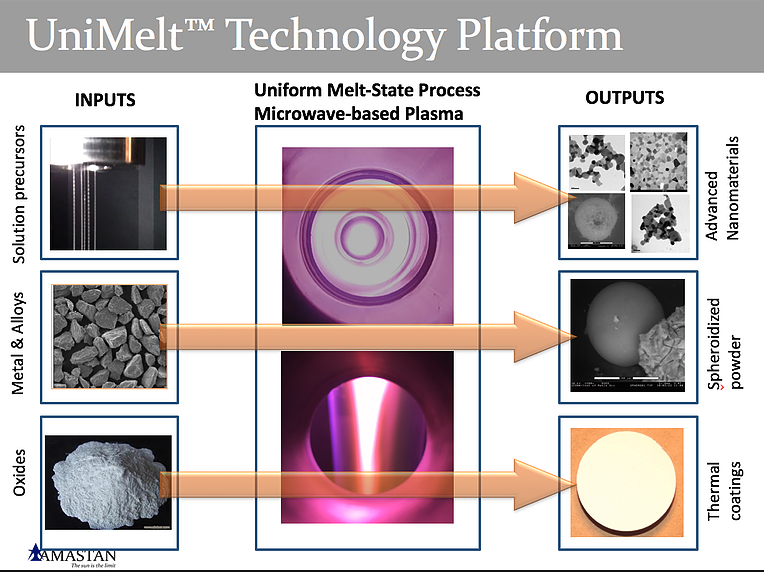

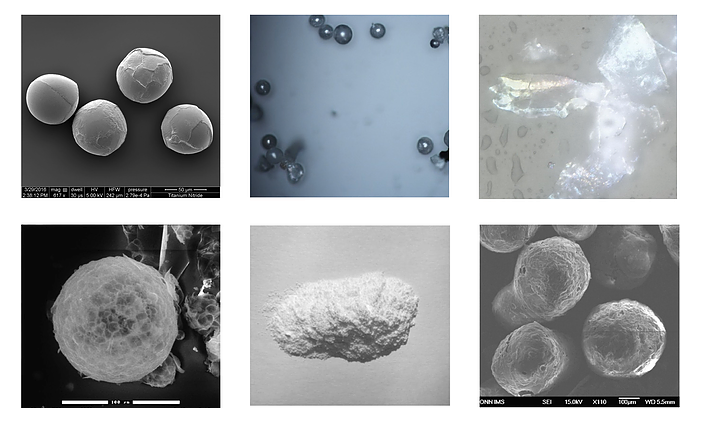

Founded in 2014, Amastan Technologies is responsible for the commercialization of patented microwave-based plasma technologies invented at the Massachusetts Institute of Technology (MIT) and the University of Connecticut (UConn). UniMelt is the company’s trademark process, which claims to be “the world’s only high-power microwave-based plasma system for creating and modifying advanced powder and particle materials.” A continous, single-step, process, Amastan applies UniMelt process to the creation of several products across advanced nanomaterials, spheroidized powder and thermal coatings. Additive manufacturing is just one of the markets that the company serves with these products.

Based in Pennsylvania, AL Solutions, Inc. specializes in the production of refined titanium materials for aerospace, automotive and medical application. For this purpose, the company developed a proprietary metal handling processing technology.

Combined with Amastan’s UniMelt technology, AL Solutions’ metal handling expertise will be used as the basis for the new Amastan Additive brand that will be formed as per the terms of AL’s acquisition.

$25 million dedicated to Amastan’s development

Amastan’s $11 million Series B-2 funding round was led by D.C. based private equity firm Anzu Partners. Following an initial series B funding of $13.85 million in Q4 2017, this round saw the contribution of existing investors Launch Capital, Material Impact, and RKS Ventures.

The terms of Amastan’s acquisition of AL Solutions, Inc. were not disclosed, however Frank Roberts, AL Solutions former CEO, is to serve as President of the new Amastan Additive brand.

“We are excited to become part of the Amastan team,” comments Roberts. “Our company has a one-of-a-kind production technology to process titanium and other metal streams from subtractive machining processes.”

“This capability will provide Amastan Additive a sustainable, low cost, and infinitely flexible feedstock source for high performance Additive/3D metal powders.”

The first line of powders from Amastan Additive are expected to rollout late 2019.

Voting is still open for the 2019 3D Printing Industry Awards. Select your Material Company of the Year here.

Subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter for all the latest 3D technology news.Visit 3D Printing Jobs for new opportunities in additive manufacturing.

Featured image shows products of Amastan Technologies’ microwave-based plasma processes. Image via Amastan Technologies