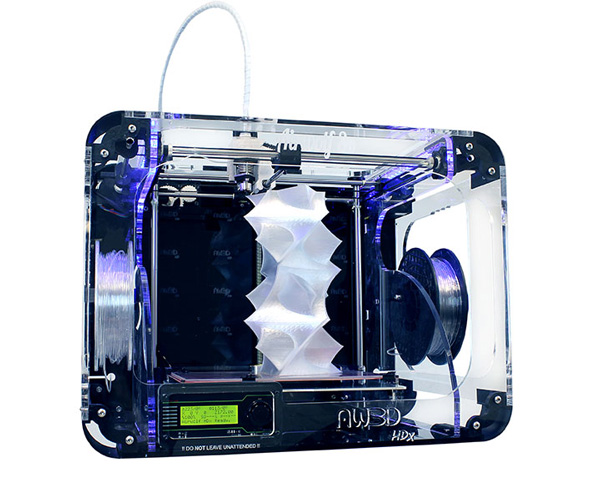

3D printer manufacturer, Airwolf 3D, based in California has introduced the world to its latest model — the AW3D HDx.

Looking like a professional design tool, the HDx is an upgrade to Airwolf’s HD 3D printer with a scaled up build volume and a particular emphasis on printing with a wider range of materials, specifically engineering-grade materials with higher temperature requirements.

Erick Wolf, founder and CEO of Airwolf 3D, explained the motivation behind these developments: “Imagine a 3D printer that can print engineering-grade materials placed on every desktop. Imagine the creativity it could unleash as engineers and artists experiment and create objects that until now were virtually impossible to affordably print. That’s our vision: to bring imagination to the desktop.”

The AW3D HDx is supplied with the company’s proprietary JRx hot end, which can consistently extrude at 315 C°, together with nylon extruder gears, a finer pitch lead screw for increased Z position accuracy and enhanced movement control speeds. All of which means that the new 3D printer is compatible with a wide range of 3D printing filaments, including, but not necessarily limited to PVA, the various nylons of Taulman3D as well as the traditional ABS and PLA (including soft PLA).

In terms of size, the AW3D HDx has an increased build volume, which now stands at 12″ x 8″ x 12″ with a printing resolution of 60 micron layers.

The AW3D HDx is supplied fully assembled and calibrated for $3,495 and the model has a four to five week lead time.