Sigma Labs, a Santa Fe-based additive manufacturing software developer, has announced a collaboration with international aerospace company Airbus to deploy Sigma Labs’ PrintRite3D quality assurance software.

Airbus will use the Rapid Test and Evaluation Program of the new PrintRite3D version 5.0 to test and evaluate metal additive manufacturing for serial production of printed parts in the aerospace industry. This will be followed by the validation of a powder bed fusion 3D printer.

John Rice, Chairman and CEO of Sigma Labs, comments, “We are honored and indeed feel very privileged to have our In-Process-Quality-Assurance tools as well as engineering staff engaged with Airbus, a leading aircraft manufacturer.”

“Our industry appears to be accelerating in its sophisticated quality requirements including highly accurate and economic third-party quality assurance. We at Sigma have committed ourselves to meet that need.”

The PrintRite3D package

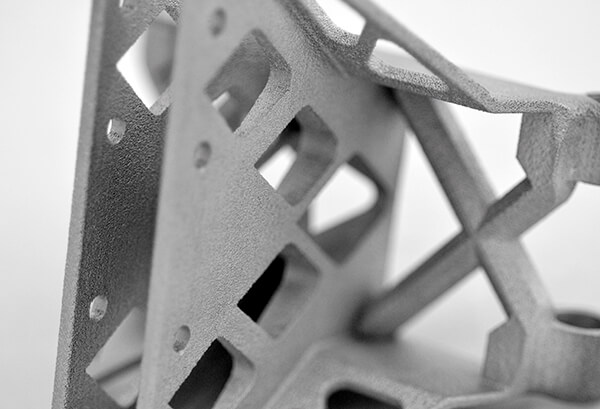

Sigma Labs’ PrintRite3D is a combination of one hardware module and two software modules for additive manufacturing quality assurance and in-process monitoring. When used together they collect and process data which users can analyse and inspect, in real-time, and implement corrections if necessary.

The company claims that as the growth and application of additive manufacturing in aerospace continues to expand, it is essential that processes are qualified in order to increase and assure the quality of parts. Working with Airbus, it aims to provide a quality assurance solution with PrintRite3D, which can deliver process knowledge and an understanding of melt pool dynamics, leading to improved process consistency for additive manufacturing.

Earlier in 2019, an undisclosed global materials and service provider in additive manufacturing had also collaborated with Sigma Labs in order to engage in its Test and Evaluation program. This was followed by news that Sigma Labs had obtained third-party validation of its PrintRite3D platform in a study by U.S. defense agency DARPA.

After launching the latest version of PrintRite3D at RAPID+TCT in May 2019, the company signed an MoU with Belgian 3D printing software company Materialise, which has also worked with Airbus. Sigma Labs and Materialise will combine their expertise and develop an integrated in-situ quality assurance (QA) system for metal 3D printing, with the aim of commercializing the technology.

The Rapid Test and Evaluation Program

Under Sigma Labs’ Test and Evaluation program, Airbus will gain access to the PrintRite3D In-Process Quality Assurance (IPQA) system. The services of the IPQA includes hardware, software, training, engineering and metallurgical consulting and support. The purpose of the program is to demonstrate the value of Sigma Labs’ PrintRite3D software, and its ability to monitor and validate material, machine processes, production consistency, and the repeatability of additive manufacturing operations.

Furthermore, the Test and Evaluation program is also expected to alert Airbus engineers of precursors that indicate additive manufacturing process discontinuities. It will allow engineers to extract actionable data to restore the process. Sigma Labs also aims to exhibit the power of PrintRite3D INSPECT 5.0 with the program, a software module that enables the in-process inspection of metallurgical properties. Ultimately, the program will hopefully lead to the qualification of a metal additive manufacturing system for serial production in aerospace for Airbus. “PrintRite3D® 5.0 provides the market with a user-friendly experience to rapidly qualify an AM metal machine for serial production, and then, in the course of continuous production runs, to be able to rectify any detectable errors,” adds Rice.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also keep connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

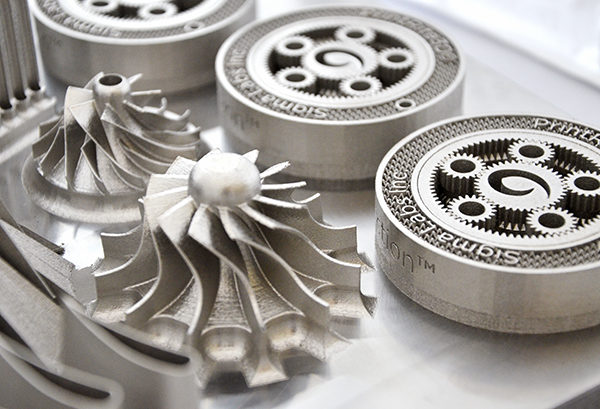

Featured image shows 3D printed metal parts inspected by the PrintRite3D platform. Photo via Sigma Labs.