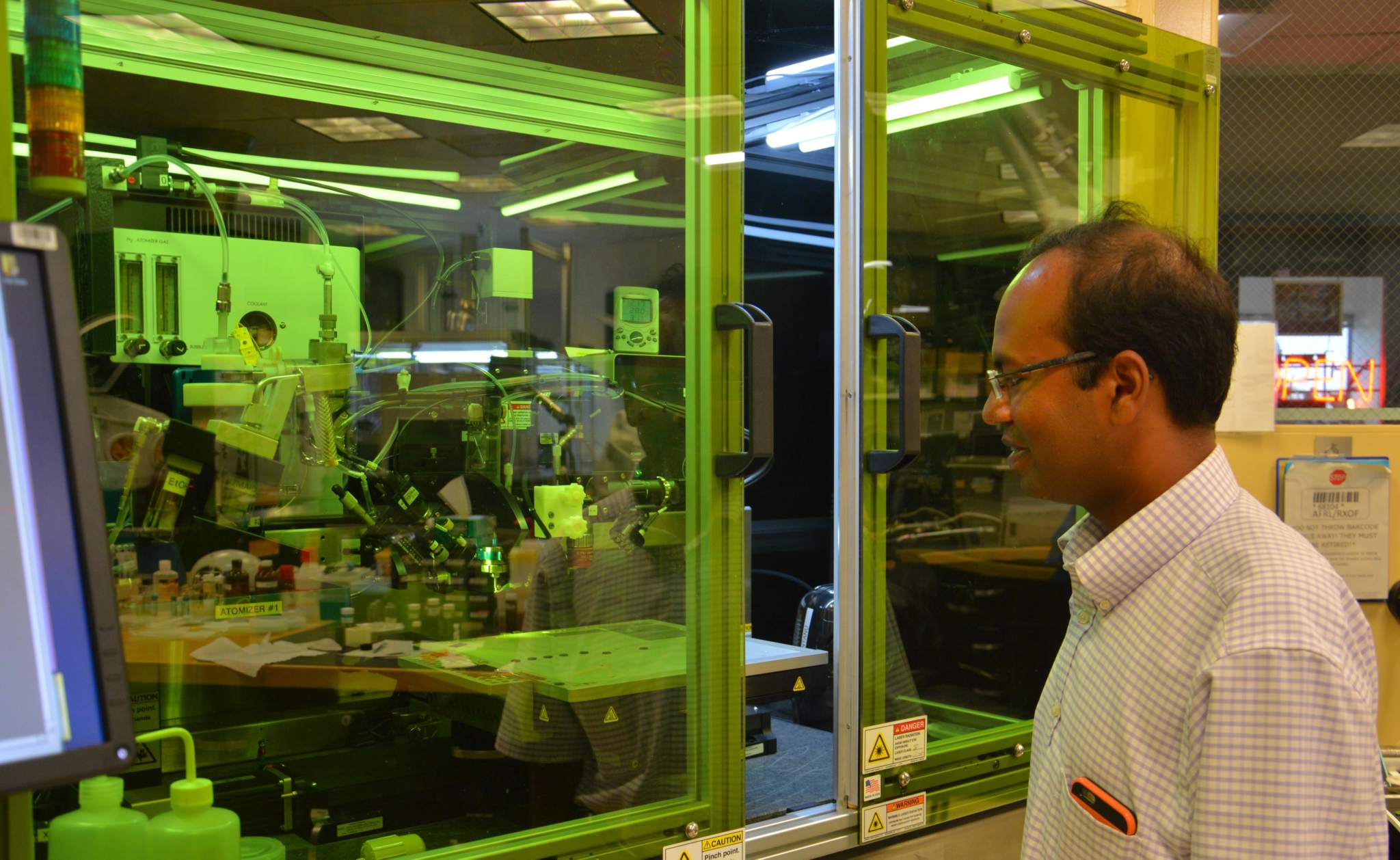

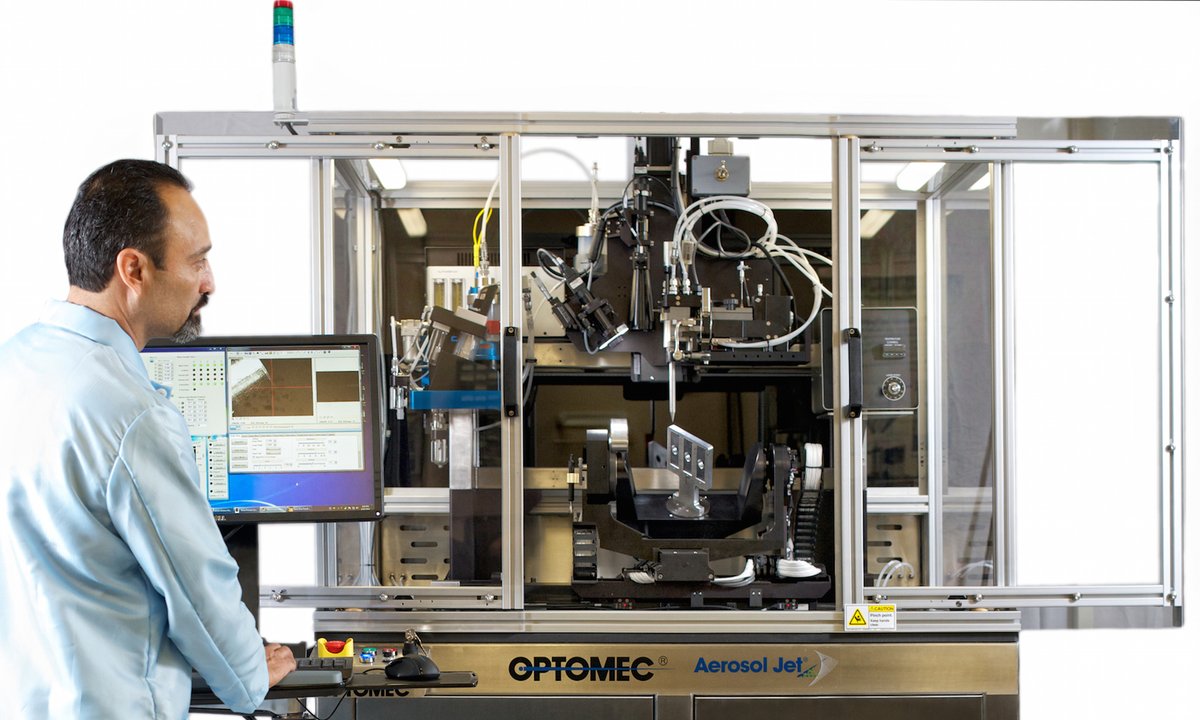

The Air Force Research Laboratory (AFRL) has published research into 3D printed solar cells. Using Optomec’s aerosol jet technology, the AFRL intend to develop a more efficient production process for harnessing solar power.

The research group expects that by providing an accessible manufacturing method, the technology can become more widely used. Leading the research project, Dr. Santanu Bag explains the project’s motivation,

Solar cells can generate electricity in an environmentally friendly way, but current, complex fabrication costs make the technology expensive. We’re looking at new ways to use materials and manufacturing technologies to make these less expensively.

Efficient sustainability

The ARFL is approaching solar cell production with perovskites rather than the conventional silicon.

Traditionally, solar cells are created with pure crystalline silicon which, as Dr. Bag points out, is both labor intensive and expensive. By using the calcium titanium oxide mineral, Dr. Bag and his team have been able to develop a more efficient production process and one without the related high costs.

Dr. Santanu Bag explains that while “solar cells can generate electricity in an environmentally friendly way, but current, complex fabrication costs make the technology expensive.”

The Air Force Research Laboratory is attempting to develop a manufacturing method which automates production of the solar cells to provide a viable industrial output. To do so, the team atomized perovskite materials which can be 3D printed with the Aerosol Jet technology machine. Having coated a flat surface with the droplets, the team created a solar cell with 15.4 percent efficiency. The paper thereby successfully concluded that, by using Optomec’s Aerosol Jet technology,

This approach enables reproducible fabrication of high-quality, printed thin-film perovskite with tailored composition, morphology and electronic properties suitable for the “lab-to-fab” technology transition.

The researchers then took this one step further by printing the materials onto 3D surfaces. While the resultant solar cells were less efficient at 5.4%, the AFRL believes there is potential for solar cells to be incorporated as wearable technology.

Albuquerque’s Optomec has showcased its ability to print onto 3D surfaces with a turbine blade for GE. The company also recently advanced its proprietary aerosol jet technology with the ability to print with copper inks. The breakthrough is expected to have a big impact on the promise of 3D printed electronics.

ColorFabb’s solar powered filament

In related news about 3D printing and sustainable energy ColorFabb are making changes to how 3D printing filament is made.

Earlier this week, ColorFabb announced they will install solar cells to power filament production. The Netherlands-based 3D printing company revealed via twitter that it will begin operating its filament production facility using solar energy.

The Dutch company recently moved to a new state-of-the-art facility in Belfeld, Netherlands and is now looking to reduce its carbon footprint.

Big decision made today!! In Q3 / 2017 @ColorFabb will start producing #3Dprinting filaments with sustainable solar / PV energy. Stay tuned. pic.twitter.com/0WxJQPnccX

— ColorFabb (@ColorFabb) July 17, 2017

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows an example of a perovskite solar cell.