German multi-material 3D printing company AIM3D has successfully concluded another funding round to further enhance its multi-material 3D printing technology.

Existing investors, such as the HZG Group, High-Tech Gründerfonds (HTGF), and other early-stage supporters, have contributed to the recent investment. This funding arrives before the launch of AIM3D’s ExAM 510 industrial 3D printer’s series production.

“With respect to the combination of size and chamber temperature, AIM3D is launching an unrivaled 3D printer. In addition to the established applications using plastics, there lies great market potential in the processing of high-performance polymers,” said Dr. Florian Bechmann, CTO of the HZG Group.

Enhancing 3D printing with granulate-based printing, and user-friendly software

AIM3D says it enhances additive manufacturing by utilizing commercially available injection molding granulate as a raw material, eliminating the need for specialized filaments. This approach offers rapid availability and cost-effectiveness. By removing the requirement for molds, setup times are significantly reduced, providing the freedom of additive manufacturing. Moreover, AIM3D’s Composite Extrusion Modeling (CEM) process enables the production of metal and ceramic components, enhancing the versatility and applications of its technology.

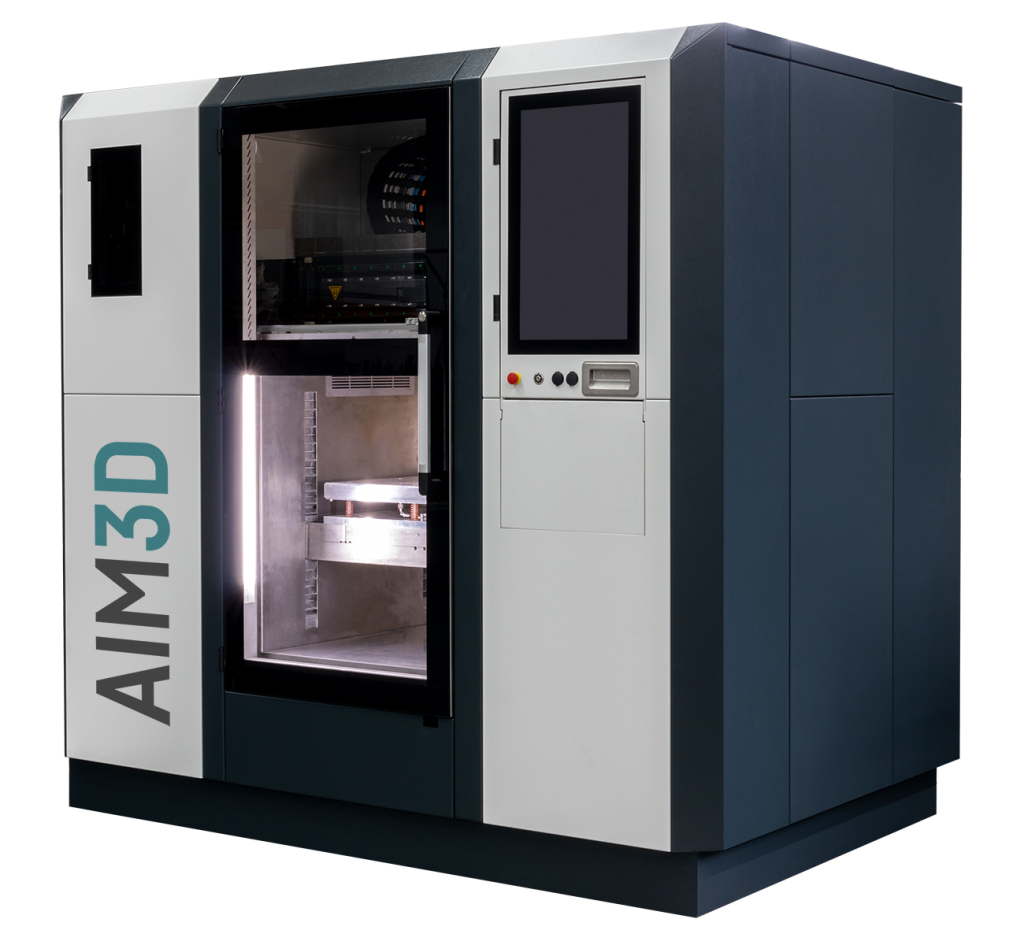

Clemens Lieberwirth, Co-Founder and CTO of AIM3D, said, “With the ExAM 510, we are now on the home stretch. The feedback from our beta customers will be considered in the final series production later this year. With the support from our existing investors, we can, at the same time, take the sales pipeline to the next level and expand our own machine park to rapidly demonstrate our technological capabilities based on specific customer needs.”

While focusing on sales expansion, AIM3D is concurrently maintaining its dedication to R&D efforts, says the company. Last year, the engineering team filed a new basic patent, introducing the novel voxelfill process. This method injects material into volume chambers, effectively filling the voxels and creating a sturdy “brick bond” structure within the component, enhancing its resistance against fractures. This process significantly improves productivity. In the coming months, AIM3D aims to initiate a funded project to further develop and test this technology for industrial applications.

Additionally, AIM3D plans to upgrade its 3D printers with user-friendly operating software. Lieberwirth says, “Existing AIM3D customers will also benefit from a software relaunch, as the systems on the machines can be updated. The use of our machines should not require any firm prior knowledge of 3D printing and should therefore be open to all employees in our customers’ production.”

Funding rounds fuel 3D printing innovation

Q.Big 3D, a manufacturer of large format 3D printers based in Aalen, recently successfully raised €2 million ($2.2 million) in a series A funding round. The funding was led by HZG Group, with participation from global engineering firm Manz AG and personal investment from Dieter Manz, the Founder of Manz AG. This funding coincides with the upcoming launch of Q.Big 3D’s Queen 1 “XXXL” large-format 3D printer. Following a beta-testing phase since autumn 2022, Q.Big 3D is now focusing on expanding sales activities for the new product, which is expected to be ready for shipment by the end of this year.

Volumetric 3D printer developer Xolo announced the completion of its series A funding round, raising a total of €8 million ($8.6 million). This comes after a successful €2.5 million ($2.7 million) seed round in 2021, during which Xolo introduced its proprietary 3D printer, Xube, and the Xolography technology for rapid 3D printing of any design. The funding was co-led by German and Austrian venture capital firms HZG Group and Onsight Ventures, Miami-based B2B tech investor SquareOne, and the German fund for deep tech and climate tech growth-stage companies, the DeepTech & Climate Fonds (DTCF). These funds will support Xolo’s “vision to reshape the 3D printing industry” through the Xolography process. Additionally, the funding ensures that the startup is well-equipped to serve novel academic and industrial R&D groups, as well as enter its first industrial market.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the ExAM 510 3D printer. Photo via AIM3D.