Following the adoption of a new 3D printer by Stratasys‘ partner reseller Cylaos, the Regional University Hospital of Brest (CHU de Brest) is seeing significant improvements in pre-surgical planning procedures.

Prior to the actual procedure, the installation provides surgeons with highly precise and comprehensive 360-degree patient-specific anatomic models, which could minimize surgical risks and time in the operating room (OR). The realistic sophistication of the 3D printed models developed with the all-in-one, multi-material, multi-color J5 MediJet over initial single-material, single-color options is “transformational”, according to Samuel Guigo, radiology and 3D printing technician at the CHU, and “sets a new benchmark for medical modeling.”

“The accuracy we now enjoy with the J5 3D printed models means our surgeons are far better equipped and prepared before going into a theater, which significantly and quantifiably reduces surgical-related risks through improved safety,” explained Guigo.

Benefiting from Stratasys J5 MediJet 3D printer

Guigo further explained that when preparing a vascular surgery, for example, millimetric precision is mandatory. “With the J5 MediJet, not only can we achieve this, but we have the flexibility to re-print the models to iterate and achieve optimal results, reproducing them with complete consistency, as required. We were simply unable to do this previously.”

According to Guigo, the implementation of Stratasys’ sophisticated 3D printing technology is a significant contributor to the efficiency of the anatomical models the hospital can deliver. According to him, the ElasticoTM photopolymer material underscores this. Quality issues are resolved by in-house Stratasys capability, which also facilitates capacity needs. Due to inadequacies in the hospital’s existing alternative technologies, the generation of some models had previously been outsourced to external providers. Nonetheless, with a level of quality that came up short of the hospital’s expectations, in addition to a rising need to effectively manage high quantities, the purchase of the in-house J5 MediJet made logical business sense.

“We can produce models on the MediJet with far greater realism than our other 3D printing technologies allow. With the Elastico material, for example, the haptic feeling and surface smoothness replicate the patient’s soft arteries much more closely,” added Guigo.

Stratasys 3D printing technology helping enhance training and patient care

Aside from pre-surgical preparation, using patient-specific 3D printed medical models produced on the J5 MediJet for on-demand mentoring can enhance patient outcomes by lowering complications, total recovery time, and hospitalization. Furthermore, surgeons can explain specific pathologies and processes to patients before surgery with a highly precise patient-specific 3D printed medical model, that has been found to strengthen a patient’s therapeutic knowledge and gratification.

The J5 MediJet has been installed at the CHU de Brest thanks to funding from the hospital’s Innoveo Endowment Fund, which is intended to aid projects that enhance patient care, quality of life, and comfort. The J5 MediJet has been used in a variety of hospital departments, along with neurosurgery, interventional neuroradiology, vascular surgery, orthopedic surgery, vascular surgery, and biomedical services since its installation.

“The MediJet means that we’re winning in every area”, concludes Guigo. “We have greater management of growth requirements and have addressed quality issues, while also improving processes and educational practices.”

Furthermore, W.INN, the innovation center founded by the CHU de Brest in 2021, was recently marked as a Third-Party Experimentation Centre as part of the government’s agenda for advancing digital health. As a result, the CHU is now cited as a key player in medical advancement on a local, regional, and national scale.

The CHU’s next goal is to establish a devoted 3D printing arm to meet the requirements of the hospital’s departments, research group, and mentoring. The hospital is focused on promoting the technology’s widespread use in the medical field, but it also has a vision for creating 3D printed anatomical models for other hospitals and biomedical engineering schools.

Medical sector benefitting from 3D printing technologies

Previously, additive manufacturing software developer Materialise introduced Mimics Planner for thoracic surgery. According to the company, this platform uses advanced 3D modeling to adequately prepare for segmentectomy and lobectomy surgeries in a matter of minutes. Mimics AI-enabled CT heart tool for heart chamber segmentation, according to the whitepaper. According to Materialise, tasks like manually segmenting heart chambers are time-consuming, laborious, and error-prone. Implementing this procedure brings many efficiencies to an engineer’s workflow by saving time and improving accuracy.

Furthermore, at the Formnext 2022, Polish 3D printer manufacturer Zortrax revealed a significant widening of its product line. Zortrax unveiled an end-to-end 3D printing package with its Powerful Trio offering, that has been validated with Henkel and BASF Forward AM, so consumers know they’ll get concrete results straight out of the box. At the show, the company also displayed a set of Ultracur3D resins validated for its machines, along with a novel 3D printer with broad medical potential.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

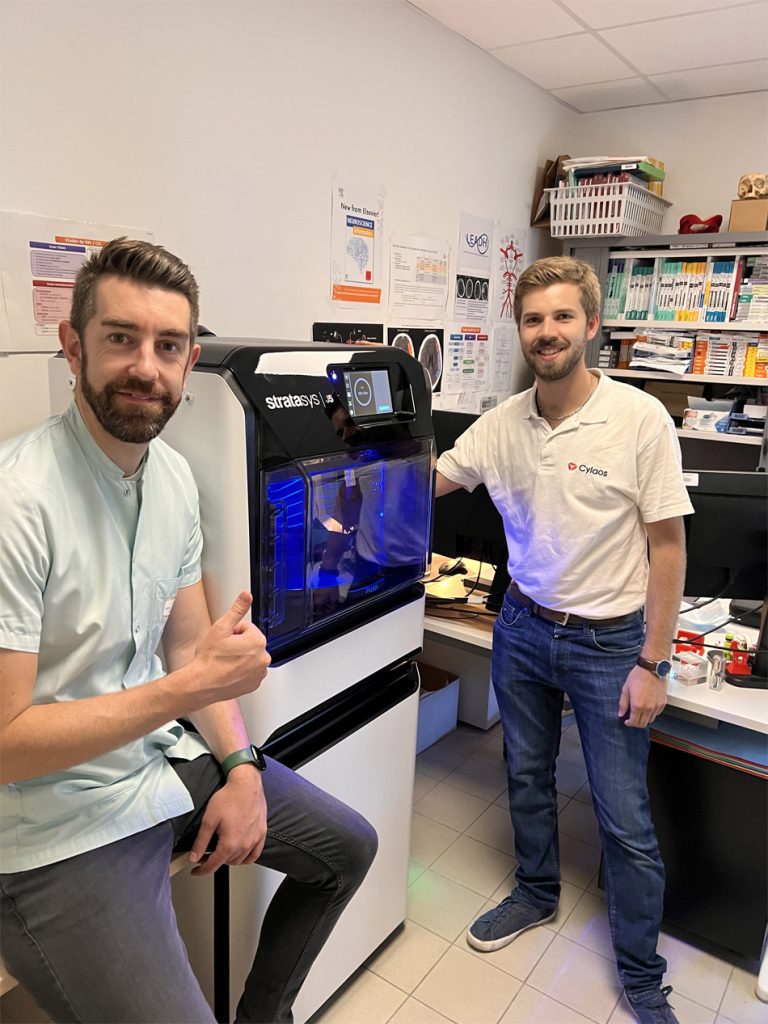

Feature image shows Samuel Guigo (left), radiology and 3D printing technician at CHU de Brest with Stratasys J5 MediJet 3D printer. Image via Stratasys.