Metal PBF system manufacturer Additive Industries has teamed up with steelmaking company ArcelorMittal to push large-scale spare part printing in the steel industry. With the use of Additive Industries’ 4-laser 3D metal printing system, the MetalFAB1, ArcelorMittal has produced on-demand, end-use spare parts for its facilities with a focus on large and intricate components in recent weeks.

Harry Kleijnen, Key Account Manager at Additive Industries, stated: “We are proud to work together with ArcelorMittal, jointly driving the business case for 3D-printed parts in the steel industry. ArcelorMittal’s typical applications have enabled us to further adapt the MetalFAB1 system to print high density, high volume parts. We are looking forward to expanding the range of applications and materials in this intense and strong collaboration.”

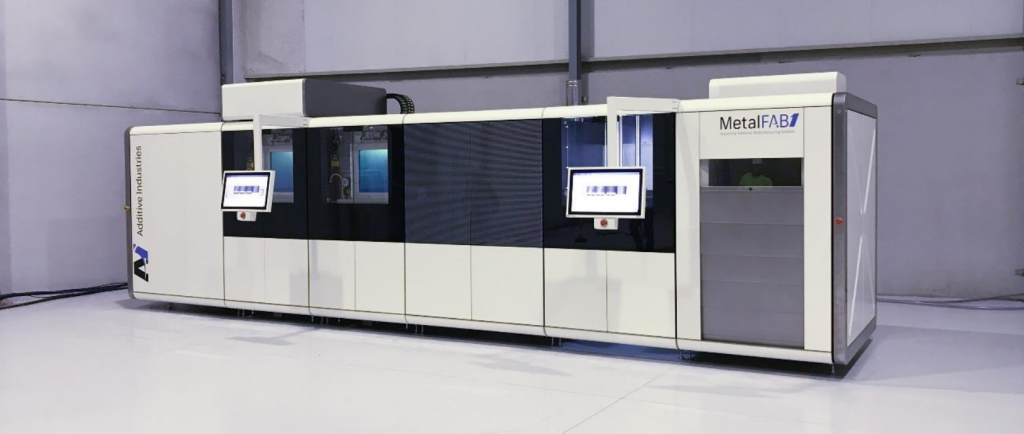

The MetalFAB1

The two companies began working together in 2017, when the MetalFAB1 was installed in ArcelorMittal’s R&D facility in Avilés, Spain. Since then, the metal 3D printer’s 420 x 420 x 400mm build volume has been used to fabricate several spare parts for steelmaking and mining operations, some of which are still in use at the facility today. The MetalFAB1 is designed with safety and material recyclability in mind, which is in line with ArcelorMittal’s focus on operator safety and environmental responsibility.

Daan A.J. Kersten, Co-founder, and CEO of Additive Industries, explained, “Innovation and market leader ArcelorMittal have helped us to stress-test our MetalFAB1 system for critical spare-part production. This enabled us to expand our experience to the steel industry from our main application markets in aerospace and automotive. It has become clear that metal 3D printing is a serious alternative for a large variety of cast parts.”

3D printing large scale spare parts

3D printing spare parts is practical in that it renders excess unnecessary stock obsolete. Parts can be manufactured on-demand and on-site, shortening the product cycle and saving on costs. The spare parts used in steelmaking operations tend to be very large as well as having to be of very high quality. This initially limited the potential applications of 3D metal printing in the facility. However, recent collaborative efforts have yielded improved quality and reliability, as well as a 4x increase in the size of the parts being 3D printed. This means the potential applications have been extended from just small size parts to large, complex, and functional spare parts.

Jose López Fresno, Head of Additive Manufacturing, ArcelorMittal Global R&D in Avilés, said, “Additive Manufacturing is an exponential technology, moving very fast. Our collaboration with Additive Industries is a clear demonstration of our ability to remain at the cutting-edge of this technology: we started by printing small specimens and have now progressed to large size and complex parts.”

Additive Industries has developed 3D metal printing for not just production tooling, but aerospace applications too. The company has previously worked with APWORKS to qualify components at Additive Industries’ Process & Application Development Center in the UK. The two companies set out with the goal of advancing the series production of certified parts for the aerospace industry. Last year, Additive Industries also worked with an unnamed aerospace client to expand the clients’ facilities with the installation of ten MetalFAB1 3D printers.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the MetalFAB1 3D printer. Photo via Additive Industries.