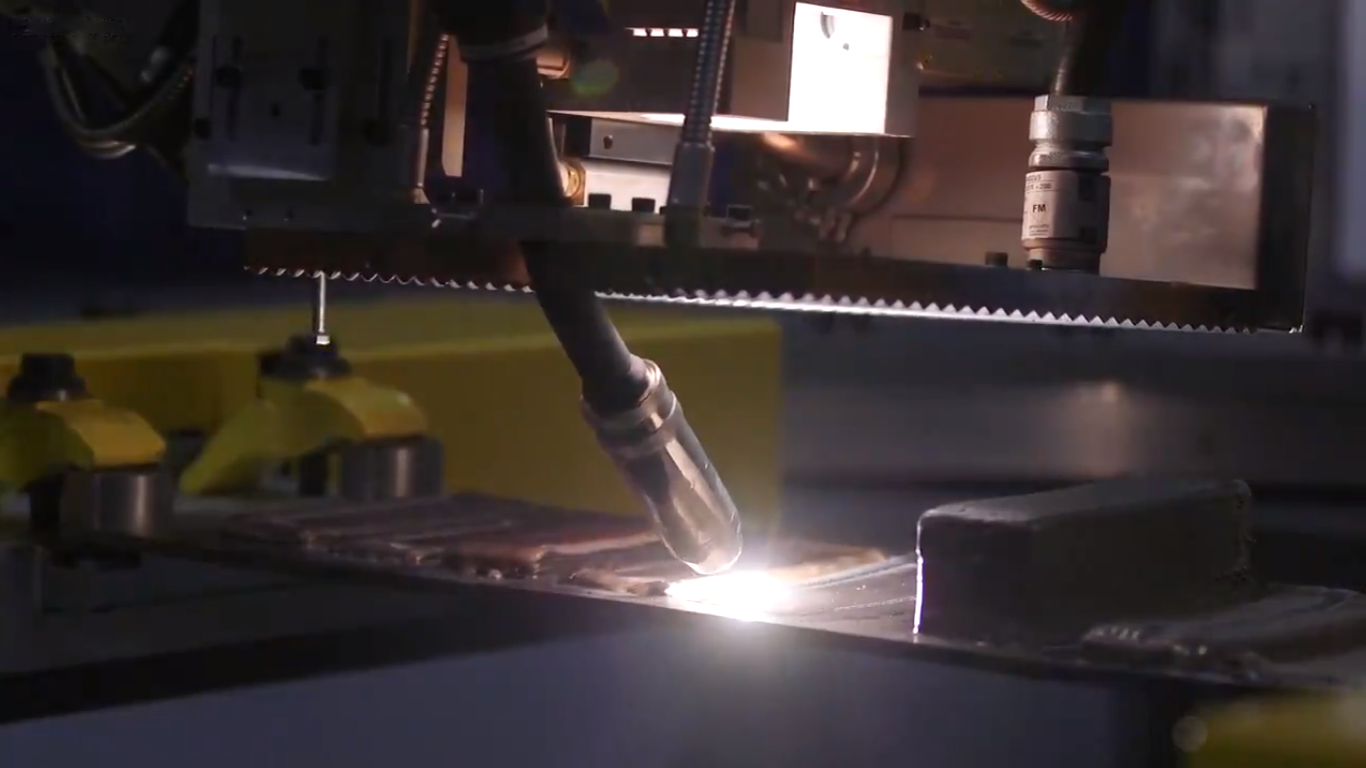

ADDere, an additive manufacturing division of Wisconsin-based manufacturing company Midwest Engineered Systems Inc., is using Laser Wire Additive Manufacturing (LWAM), to produce industrial parts for the aerospace and trucking industries.

“Currently, the AM focus has been on powder-based metal systems,” said Scott Woida, President of ADDere. “That focus had a lot of potential markets stuck on the outside looking in but those industries now see a legitimate 3D printing roadmap for their parts through what we’ve been doing with ADDere.”

Laser Wire Additive Manufacturing

Last year, ADDere, began offering its services as a 3D printing firm. Following this, the company demonstrated its large scale additive manufacturing capabilities with the production of a 5ft 11in stainless steel turbine blade. Produced in the course of one single 30-hour run, the blade’s height has a tolerance within 0.5mm of its designed height.

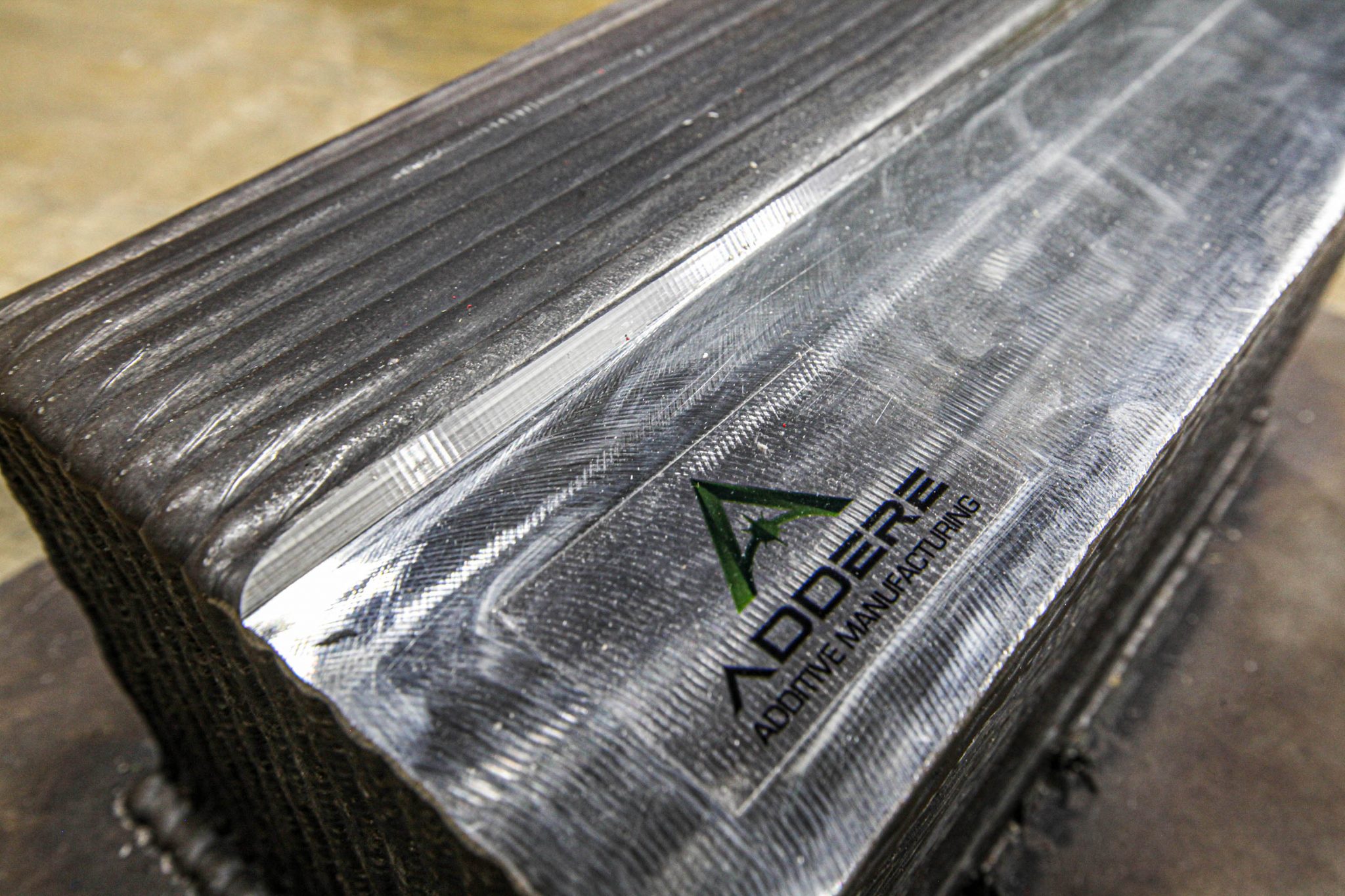

Most recently, ADDere has 3D printed blocks from titanium and stainless steel measuring 15 x 15 x 30cm and weighing 32kg in six hours. The steel blocks, which have the same dimension, are heavier weighing 55kg. The creation of these parts aims to further demonstrate the capabilities of its LWAM system. Pete Gratschmayr, VP of Sales & Marketing, ADDere added:

“These blocks show we can 3D print parts with a substantial mass in a relatively competitive timeframe with casting. Now real conversations can be had about printing large, high mass components like transmission cases, truck frames, and turbine engine mounts without adding ‘in the future’ to the sentence. We can do it today.”

A casting alternative

ADDere’s LWAM system is said to be over three times the size of most powdered metal-based systems on the market, featuring a build area of 2M x 1M x 1M and 2000kg capacity. It produces large scale, near-net-shape metal parts, and presently supports off-highway, energy, aerospace, marine, and defense firms.

Last year, the company released a whitepaper on designing for Laser Wire Additive Manufacturing (LWAM). Woida continued, “The ADDere system has proven its capability in reducing time to market for products that would previously rely on casting processes.”

Want the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows a 3D printed steel block with a machined section. Photo via ADDere.