Additive manufacturing consultancy firm The Barnes Group Advisors (TBGA) has released a study looking at the potential impact of an additive manufacturing production campus for the Pittsburgh International Airport. Known as Neighborhood 91, the 3D printing hub is planned for construction at the airport sometime in 2020 and will form part of the Pittsburgh Airport Innovation Campus. The development will sit on 195 acres directly attached to Pittsburgh International Airport.

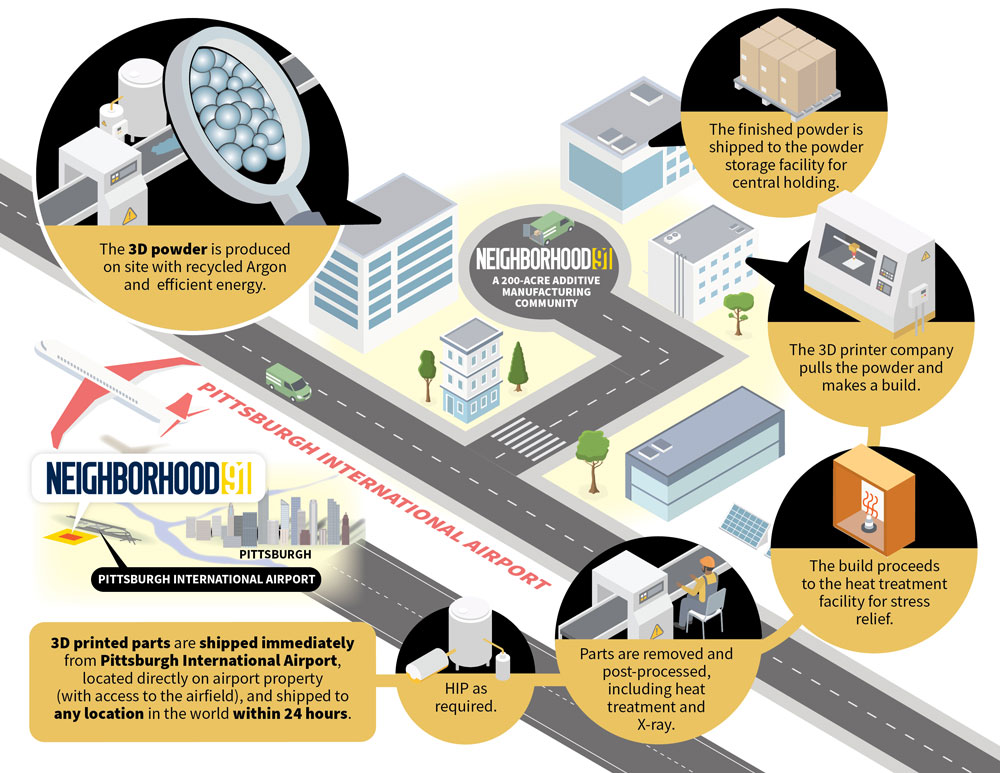

The campus has been designed to house a complete end-to-end additive manufacturing ecosystem; it features all the necessary components that make up the 3D printing supply chain. TBGA’s study has revealed the overall economic benefits that Neighborhood 91 could have for Pittsburgh International Airport, mainly revolving around a reduction in production costs, simplified supply chain, workforce development, and reduced energy consumption.

Commenting on the many cost impacts of a concentrated AM production campus, TBGA ADDvisor Services Leader and report co-author, Laura Ely, stated, “The current AM production supply chain is fragmented.”

“This study validates that Neighborhood 91’s centralized campus will significantly reduce cost and the need to manage parts across a dispersed supply chain.”

What is Neighborhood 91?

Neighborhood 91 was initially announced in late 2019, by Pittsburgh International Airport and the University of Pittsburgh. Launched to help make Pittsburgh a world leader in additive manufacturing, Neighborhood 91 is a new concept attempting to “condense and connect all components of the AM/3D Printing supply chain into one powerful production ecosystem.” Its placement at the Pittsburgh Airport Innovation Campus, built adjacent to the airport terminal and runway, is intended to leverage the shared capital resources of facility partners, including the microgrid energy system, recycled argon, and communal powder facilities. It will also be situated near two major highways, 18 railways and the largest inland port in America for globalized cargo options.

Known as the “Steel City,” Pittsburgh is a historic manufacturing hub for the U.S. In addition to steel, the city has expertise in aluminum, glass, shipbuilding, petroleum, and electronics production. Leveraging this history, Pittsburgh International Airport is seeking to establish the city as a “home” for additive manufacturing through Neighborhood 91.

TBGA has provided strategic input into the creation of the additive manufacturing campus, having also aided Pittsburgh International Airport in the creation of an AM cluster strategy. Additional partners include argon gas supplier and gas recycling specialist Arencibia.

The benefits of an additive manufacturing cluster

From its report, TBGA has determined that Neighborhood 91 can act as a catalyst for additive manufacturing industrialization and innovation with the creation of a cost-efficient ecosystem.

Specifically, the impact of the additive manufacturing production campus can lead to benefits such as a 25 percent reduction in production costs for parts, and 30 percent for powder, according to TBGA’s report. It can also potentially reduce manufacturing lead times by 80 percent, and reduce transportation costs and miles for powder to part production by at least 80 percent as well. Neighborhood 91 may also have a positive impact on R&D productivity and innovation, and allow for a reduction in learning curves and under-utilized equipment.

TBGA Founder and Managing Director, John Barnes, noted, “A cluster does two key things: It enables process owners to focus on developing and optimizing their core process, and it creates a skilled regional labor pool.” It is also a win for the region, he added, “because innovative companies locate near other innovative companies; this is an area where Pittsburgh, specifically, has been successful through the years.”

Focusing on sustaining additive manufacturing development and promoting industrialization of 3D printing, TBGA’s most recent activities have revolved around initiating a number of training agreements with key industry stakeholders in Europe and North America. It has signed agreements with the likes of SLM Solutions and Tiziri Advanced Manufacturing Technologies to provide training in additive manufacturing to their customers.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows carbon being loaded onto a plane. Photo via Neighborhood 91.