In this edition of the 3D Printing Industry news digest Sliced, metal additive manufacturing enables a disabled pilot to fly again; the functionality of color 3D printing is explored; and automation is used to advance aerospace parts.

Read on to learn about updates from AIDRO, KUKA, HP, Spatial Corp, GEFERTEC, Anisoprint, Polymaker, ADDere and more.

3D printing control system takes flight

AIDRO, a hydraulic equipment producer based in Lombardy, Italy, has used metal 3D printing to allow a disabled pilot to fly once again.

Under the ServoFly project, a group of Italian designers developed a device that adjusts the throttle control bar of a plane engine as well as an aircraft cockpit “plug-and-fly” flight control system, named “ServoFly T4/1”. The personalized system was realized through selective laser sintering (SLS).

The recipient, Mattia Negusanti, lost mobility in one of his hands due to an accident during his time in the Italian military. The ServoFly T4/1 allows Negusanti to control an aircraft despite this injury.

KUKA joins Pacific Northwest Aerospace Alliance

In the latest partnerships, KUKA, a German manufacturer of industrial robots and solutions, has joined the Pacific Northwest Aerospace Alliance (PNAA), which aims to strengthen the manufacturing supply chain to provide lighter, more fuel efficient, and safer aircraft.

Acting as a participating member, KUKA will share its knowledge on automation at PNAA conferences and events, with the intention of bettering the aerospace industry. Steve Green, general manager at KUKA, explained:

“Technology in the aerospace industry is constantly changing, as are the requirements for the safety and comfort of the aircraft’s passengers. At KUKA, we develop fast, flexible, and customized products for our aerospace customers to make their jobs a little easier.”

“By joining the PNAA, we can share our industry expertise with others, as well as learn from other industry leaders’ experiences. We’re excited to be a part of the effort to spur innovations in the industry alongside some of the top aerospace companies in the world.”

Elsewhere, Anisoprint, a Russian 3D printer and composite materials manufacturer, has partnered with Chinese materials company Polymaker to develop composite parts with new chemical and mechanical properties.

As a result of this collaboration, Anisoprint will use its Composite Fibre Co-extrusion (CFC) technology to process any plastic with a processing temperature up to 270°С as a matrix material. Polymaker will supply a wide range of engineering 3D printing materials, including PETG, ABS, PC, PLA, and PAs, to produce the 3D printed composite parts.

A 3D printed clevis part made from PETG and Composite Carbon Fibre (CCF) for a dairy production line was created as a proof of concept on this partnership. This part was made to be resistance to peroxide, as well as both strong and lightweight.

The HP 3D Print Design Competition

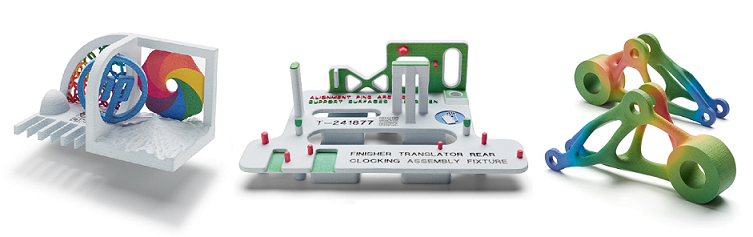

The HP 3D Print Design Competition is encouraging creators to demonstrate the functionality of color-based additive manufacturing. Using its Multi Jet Fusion technology, applicants must put forward models measuring 12 x 6 x 8 inches that implement color in a valuable way, such as surgical models.

Submissions will be accepted until September 5, 2019. Following this, the public can vote for their favorite design. The winner will be announced by October 15, 2019 and will receive a HP ZBook 15 G5 Mobile Workstation.

HP Multi Jet Fusion technology is also now being used to develop personalized leg covers, in a project by Design Reality and prosthesis start-up LIMB-art.

Exploring metal additive manufacturing

SLV Halle, a non-profit, German research institute, has purchased an arc405 metal 3D printer from GEFERTEC. Professor Steffen Keitel, research institute director, stated, “This enables us to drive the strategic expansion of our research infrastructure forward and make it easier for metalworking companies to integrate additive manufacturing processes.”

In Pennsylvania, Solar Atmospheres, a provider of vacuum heat treating services, has donated and installed a laboratory furnace at Lehigh University’s Rossin College of Engineering and Applied Science. In conjunction with Pennsylvania’s William and Myrtle Jones Foundation, the donated furnace, known as the Mentor, will enable experiments in metallurgy, particularly based around additive manufacturing.

In software, Spatial Corp, a Colorado-based subsidiary of Dassault Systèmes has released the 2019 1.0.2 toolkit with enhanced 3D modeling performance, improved diagnostics, and additional interoperability features.

Californian software provider DigiFabster, has introduced Guadalajara-based Shift 3D, as its Platinum Reseller Partner for Mexico. Valente Espinoza Contreras, CEO of Shift 3D, said, “We’re impressed by the software solution offered by DigiFabster. Having the ability to automate quoting, order entry and project management is a huge opportunity for our customers.”

Wisconsin technology developer ADDere has released a whitepaper on designing for Laser Wire Additive Manufacturing (LWAM).

“The ADDere system has proven its capability in reducing time to market for products that would previously rely on casting processes,” said Scott Woida, president of ADDere, a division of Midwest Engineered Systems (MWES).

“Delivering the same grade part in days rather than months – and we’re talking about a part that can be the size of a truck transmission or larger. That’s a game-changer.”

Lastly, Global standards developer ASTM International will host its Fourth ASTM Symposium on Structural Integrity of Additive Manufactured Materials and Parts from October 7-10, 2019 in Washington, DC. This event will provide a forum for further discussions on design principles, as well as qualification and certification criteria.

Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook for more additive manufacturing news.

Join our 3D Printing Jobs to post a job or advance your career in 3D printing now.

Featured image shows Sliced over KUKA robotic arms. Photo via KUKA.