The general consensus, and my own personal idea, for FFF technology evolution is that of moving away from a 3-axis cartesian or delta extrusion head 3D printers and into robotic assembly systems that operate through one or more multi-axis robotic arms. These systems already exist in various sizes; however, in the future, they may become smaller, more precise, and more importantly, affordable. One contender to be among the first to bring this technology to a wider public is 5axismaker, a young firm which 3DPI covered when they first landed on Kickstarter.

While their KS project was very much focused on subtractive technologies, now they are getting more directly involved into 3D printing applications and are showing off the use of their machine for conformal 3D printing – that is, on an already finished, curved, surface. In this case, the robotic technology shows off the ability to recognize and adapt to a pre-existing shape.

The 5 axis robotic arm was used to 3D print continents on a pre-printed hemisphere, conforming to the surface of the base. This process was able to cover up the layered texture of the 3D printed hemisphere with custom patterns, thus going beyond the general limitations of a standard cartesian or delta filament-based 3D printer.

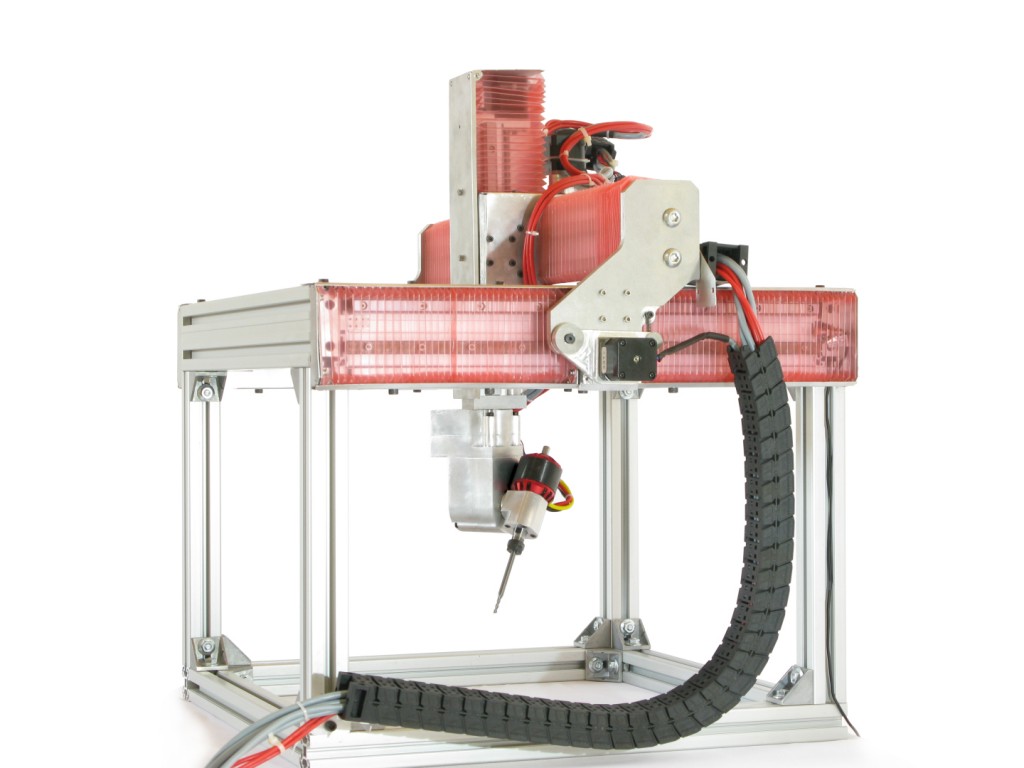

The 5axismaker machine measures 600x600x600 mm (its size can also be customized) with a basic working volume of 400x400x400 mm. It can already use a wide range of different tools, including a milling head, a touch probe head (for 3D scans) and, of course, an extrusion head for 1.75 ABS and PLA filament.

This 5 axis 3D printing process process can be used to increase the structural integrity of a 3D printed object, as well as for a range of other applications. Although 5axismaker makes no reference to it, it seems clear to me that the possible implementation of multiple arms working with multiple materials could open up a broad range of new possibilities, especially in the biomanufacturing sector. The team said more news is on the way and we cannot wait to see what it is.