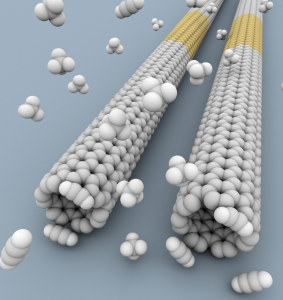

3DXTech has introduced two new grades of ESD-safe materials that have been developed specifically for use in desktop 3D printers. ESD filaments are a family of specialty filaments that utilize multi-wall carbon nanotubes (CNT) to obtain targeted levels of electrical conductivity while retaining maximum base resin properties. This is huge news for designers in the semi-conductor fabrication market. Up until now, if they wanted to create prototypes and limited production components such as casings, connectors, fixtures, jigs and masks, they would be stuck searching for reliable open-source ESD 3D printing materials. The materials had to have very refined characteristics including consistent electrical properties, cleanliness, superior mechanical properties and improved chemical resistance.

3DXNano ESD ABS is manufactured from 100% virgin ABS resin and multi-wall carbon nanotubes, while 3DXNano ESD PETG pays special attention to consistency, using a “proprietary formulation of virgin PETG resin, multi-wall carbon nanotubes and process/dispersion modifiers.” Both of these new 3DXNano products “target 107 to 109 Ohms surface resistivity” and are capable of being used on a wide variety of desktop 3D printers. The conductivity of ESD CNT filaments increases as the extruder temperature increases, but 3DXTech is careful to warn users not to exceed 270°C when printing using their new products to avoid polymer degradation.

So why isn’t there a PLA option, and what specs does your 3D printer need in order to use these ESD filaments?

According to Matt Howlett, the President of 3DXTech, pretty much any desktop model will do.

“Our 3DXNano ESD products will work in practically any desktop 3D printer with a heated build platform. We chose to incorporate CNTs into these products because they offer exceptionally consistent ESD properties with very low loading rates. This allows for the filament to be more ductile and have less particulate contamination compared to traditional carbon black additives. The base resins we used – ABS and PETG – are very familiar to the 3D printing community and suitable for most desktop 3D printers. Whereas ABS is suitable for the majority of applications, we needed a more chemically resistant polymer for applications where improved chemical resistance is needed. We chose PETG because it is a permanently amorphous polyester that exhibits very good chemical resistance as well as

exceptionally low moisture absorption, and excellent dimensional stability.”

So, the extruder temperature average for CNT 3D printing has come down, anyone can buy a spool of either ESD filament for $58, and make much stronger 3D prints, which is pretty amazing.

“3D printed masks allow us to improve quality, increase efficiency, and can be printed ESD-safe with great flexibility of design. So even small companies with small board runs can benefit with professional masking products. The 3DXTech materials are ideally suited for printing ESD-safe parts. We typically print with their ESD ABS grade unless the customer is using a solvent-based conformal coating – then the PETG grade is more suitable. Before we started 3D printing these parts, our customers often used masking tape or CNC machined masks. Masking tapes are slow and imprecise – often leading to quality issues from incorrect masking. CNC machined masks are expensive compared to our 3D printed parts, so smaller customers who couldn’t afford the CNC machined parts can use our 3D printed parts and not worry about the issues with masking tapes. Essentially, 3D printed masks allow us to improve quality, increase efficiency, and can be printed ESD-safe with great flexibility of design.”

Get ready for a new wave of design solutions and 3D printed innovations!