As far as prototypes and proof-of-concept machinery goes in the 3D printing industry, it’s best to be a little weary. A proof of concept may be have quite a dip on its product roadmap ocean floor, and everyone can think of a time when they saw a new machine surrounded by a lot of jargon, waiting for it to eventually disappoint. I think the reason a lot of people add so much jargon to their proof of concepts and prototypes is because the ideasre big, and the vision and enthusiasm are endless. But the most interesting Makers and inventors are the ones who put their imagination in a straightjacket, trying their best not to get too excited or speak beyond their means.

That being said, ideas often inspire others, and I think showing off a proof-of-concept prototype for that reason is beneficial to others who may need a boost or a change in direction. All of the amazing inventions and ideas that have sprung from Makers and companies of all sizes, to me, are part of a living jigsaw puzzle of inspiration, coupled with all the effort needed for realizing these ideas.

That being said, isn’t the thought of a relatively limitless platform for a roving robotic 3D printer from Brazil a really cool idea? I think so.

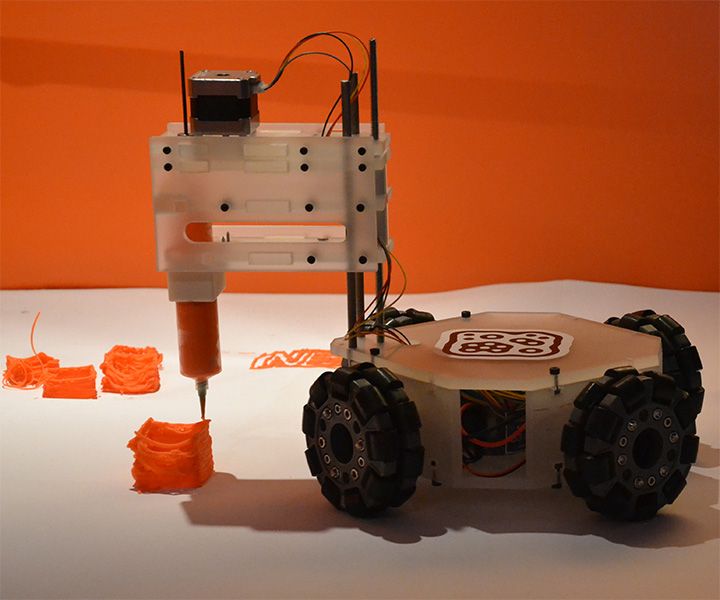

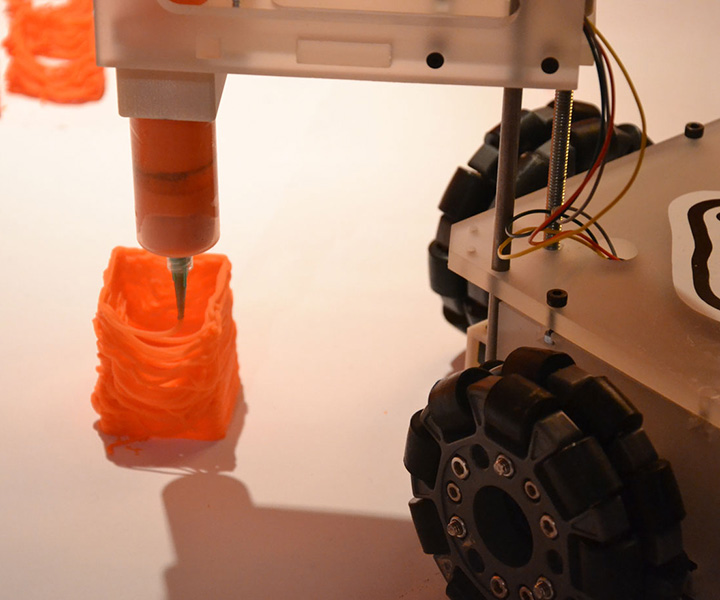

A few thoughtful industrial designers from LIFE and NEXT created this cute little mobile 3D printer, which they call the 3&D Robotic printer. The one shown here is obviously a proof of concept, using a syringe to print materials such as clay and ceramics.

With a combination of omni-directional wheels, an embedded Arduino microcontroller, and a video tracking system, the 3&D bot wirelessly communicates with a host computer by way of a built-in receiver. There is some pretty obvious layering going on here, but it will be exciting if they add an extruder to it and improve the video tracking system, as the machine’s accuracy could increase.

But let’s get back to the idea behind it. Having a roving 3D printer has a lot of interesting implications. Somebody could be looking at this, and imagining scaling up the 3&D bot, as well as some other mini-mobile 3D printing bots, like the Minibuilders, which Michael Molitch-Hou covered back in June.

If you scale these up to be construction grade 3D printers, add sophisticated live feedback laser scanning and augmented reality software, create material that doesn’t crumble in the elements, or perhaps has metal materials mixed into it, you could 3D print giant flat structures, like roadways or foundations. The obvious limitation here is that the 3&D bot can’t print very high because it has no way to extend positively into the z-axis.

There is a fleet of integrated construction-grade 3D printers on the way. And this is just one way someone will be inspired by this idea. The imagination and effort needed to realize every future idea is embedded in every inspired idea turned reality in the past and present.