In case studies all around the world, 3D printing is growing as an effective method of making patient-specific medical implants. Typically, these implants are made based on data gathered from CT/MRI scans and x-rays.

However, CT/MRI/x-ray image data is not ideal for direct-import into CAD modeling software.

A new report from researchers in Jiangsu Sheng, China, demonstrates a 3D printing bone treatment that uses handheld 3D scanner data to make models.

An effective treatment for humerus issues

In the study, researchers examine three common bone/cartilage defects:

- “large segmental defects of long bones” i.e. In which a large portion of a bone has to be cut/or is absent in e.g. the shinbones or the forearm.

- “free-form fracture of femoral condyle”, A shattering of the ball joint at the end of the femur.

- And a “chondral lesion,” which is damage to cartilage found in the ankle.

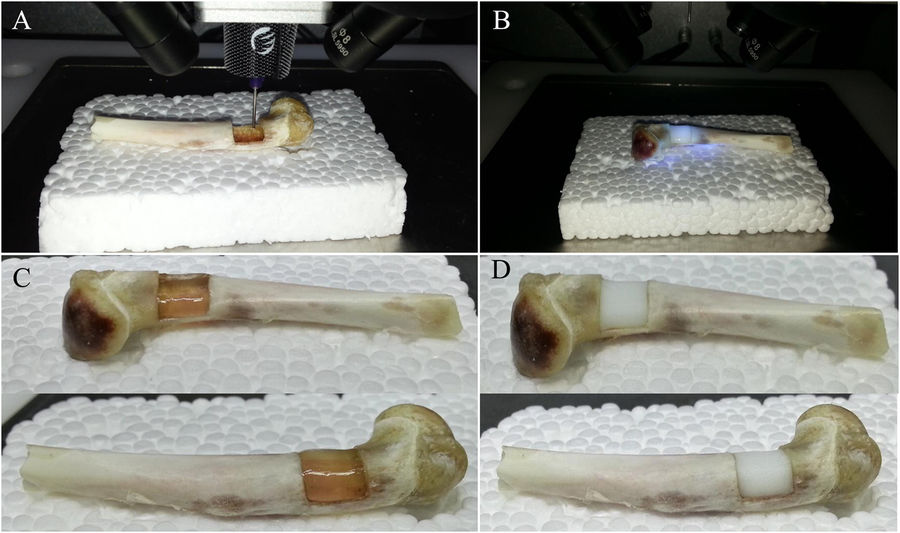

The Einscan Pro 3D scanner from Shining 3D, visited by 3D Printing Industry April 2017, is used in the experiment to create digital models of each of the sample defects. For accuracy, each bone is also placed on an accompanying turntable, allowing the Einscan to remain stationary as it collects data.

Scan-print-scan

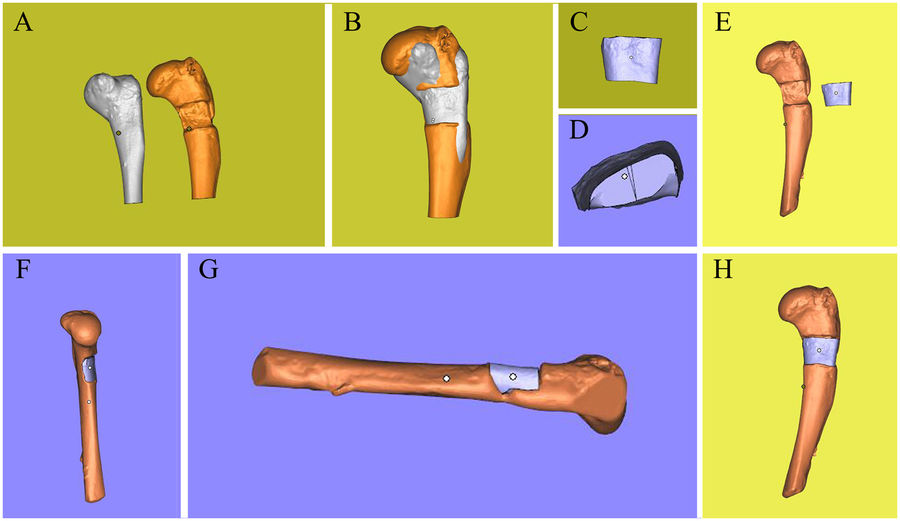

With the Einscan, a point-cloud is created which can be directly imported into CAD software, and stitched together to make a digital 3D model. This model is then used to create subsequent fillers to fit the voids in each bone.

Hydrogel is used to write the segments directly into the corresponding part of the bone.

To prove efficacy of the designs, the bones complete with 3D printed hydrogel content, are scanned a second time and compared to healthy models imported into Geomagic Studio 12.

The perfect fit

Comparisons found that “the defects of bone and cartilage were restored perfectly in situ using 3D bioprinting.” Though this method would be significantly more complicated to perform with fractured bones still inside the body, the study demonstrates promise for “the development of correlative technology,” i.e. 3D printing plus scanning.

Additionally, the authors conclude “this method provided a novel approach to treat open injuries in the skeletal system and might be more effective in some special cases.”

The study was completed by a multidisciplinary team of researchers from Southeast University, Nanjing Medical University, Nanjing University and Nanjing Normal University. Full details are available open-access in the journal Scientific Reports.

Never miss the latest medical 3D printing research and more – sign up to the free 3D Printing Industry newsletter, and check out more of our best stories on on Facebook and Twitter.

Register your research expertise on our 3D printing jobs site here.

Featured image: Bone models achieved using 3D scan data by the Einscan Pro, via Lan Li, Fei Yu et al. Scientific Reports.