At Drupa 2016, the Industry Standards and Technology Organization Printer Working Group will present a new standard for communicating 3D print jobs.

Is the 3D printing industry getting its house in order and adopting standard practice across the board? We think it is and the new standard file format and collaboration platform that is on the way from MyMiniFactory could help drag the disparate strings of 3D design together. That will help us all go forward.

Compatibility issues simply get in the way. If we can find a simple format that everyone can work with, then the industry as a whole will feel the benefit.

Growth will come when we work together

The Working Group Co-chair Paul Tykodi will take to the stage on the 3D Fab + Print stand at Drupa. There he will explain how simply standardising the printing mechanism and other parts of the 3D printing and design cycle will help us grow.

Adding a 3D print environment to the Internet Printing Protocol is all it will take to reduce costs across the board, eliminate problems and make it simpler for people to simply enjoy 3D printing.

Anything that adds friction will cost us designers in the long run and the printing protocol needs to get better in any case.

We can draw a parallel with standard inkjet printers, which started out with proprietary hardware in the 1940s. It wasn’t until 2000 when we started to get mature OS-level drivers. Even then, we still had problems.

Driverless printers changed everything

Now most printers are plug and play and, thanks to IPP Everywhere, we can now print wirelessly without drivers. There is almost nothing stopping 3D printing learning from those growing pains and jumping straight to driverless printing, which will save a mass of custom code and headaches for the end user.

3D printing could expand by up to 27% year-on-year according to several global market intelligence agencies. That number could even prove conservative, as the number of 3D printers shipped in the first three quarters of 2015 was 35% up on 2014.

The early adopters are one thing. But to maintain this growth and achieve the dream of having a 3D printer in every household, the whole industry is going to have to work to make the process as painless as possible.

We have to make printing easy

The general public simply does not want to struggle with drivers. They don’t enjoy technical challenges and 3D printing will have to become as simple as producing a black and white document right now.

Then we need to work on file formats, which are a mess right now. Designers are collaborating by holding up sketches and rough 3D prints up to webcams. That is just not the way to run a high tech industry.

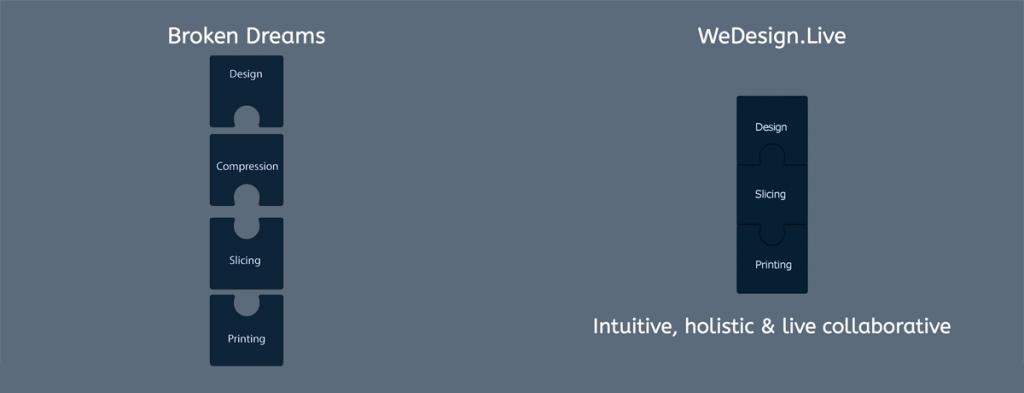

Designers want to work together and open source hardware is the future. A collaborative platform like wedesign.live is the answer, as well as a standard file that anybody can work on. Initially called MP5, the wedesign.live project wants a simple file that designers can share, work on and share again.

The Google Docs of design?

The Cloud-based platform has evolved beyond that now and we’re approaching a Google Docs-style design program where a team from around the world can have input in real time. An integrated slicer means anybody can print, too.

This platform is more or less the end goal, it’s done for us and now we just need to wait for it to arrive and then help develop open source hardware and design.

Collaboration is a mess right now, but a harmonious, standardised future is just around the corner. We’re sure it’s going to make a massive difference and anything that gets us closer to that Utopian vision just has to be a good thing.