3D printing has been used to help make a laser-powered phone charger in a study at the University of Washington (UW). The high-tech, sci-fi device has been made by the team as a possible wireless power source for rechargeable electronics, and is fully designed with safety in mind.

Could the technology untangle the humble plug?

Using a laser to wirelessly charge a smartphone safely across a room

Engineers at the University of Washington have developed a method to safely charge a smartphone wirelessly — using a laser. Read more: http://www.washington.edu/news/2018/02/20/using-a-laser-to-wirelessly-charge-a-smartphone-safely-across-a-room/

Posted by University of Washington News on Tuesday, February 20, 2018

Mobile charging without getting fried

To generate enough power to charge a mobile phone, the charging laser needs to emit a steady 2 W rate of energy. Though a relatively low wattage when compared to a household light bulb, this rate, and the fact that it is a naked beam of light, still poses a danger to any human that could come into contact with the beam. For this reason, as explained by Shyam Gollakota a UW associate professor that worked on the project, “Safety was our focus in designing this system.”

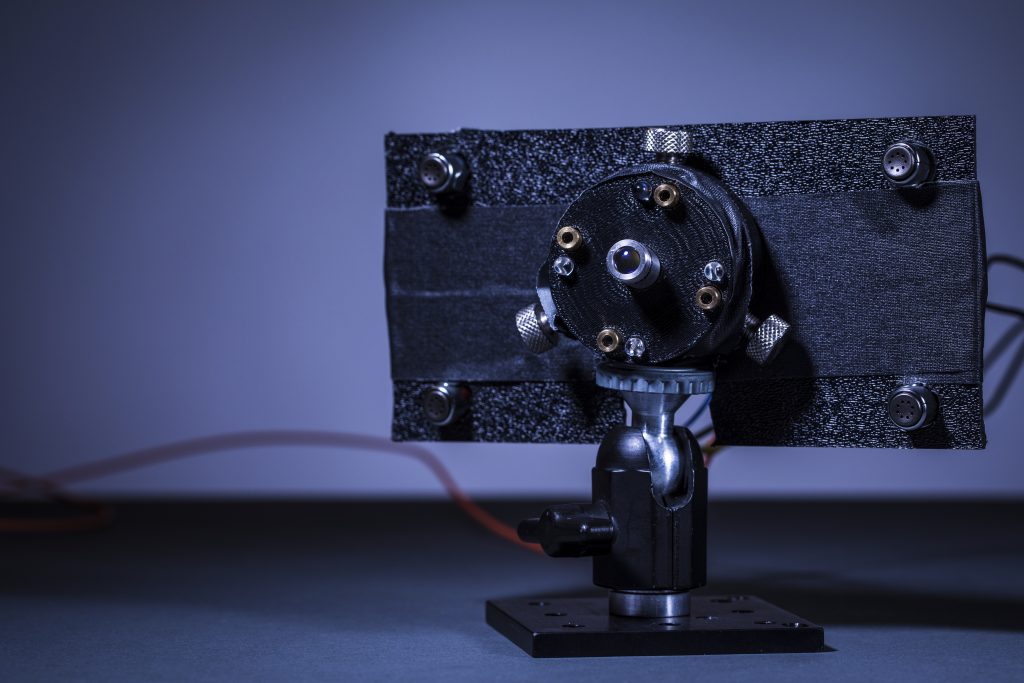

UW’s device consists of a central, charging laser beam, creating charge when it comes into contact with a power cell attached to the back of the mobile phone.

The central beam is surrounded by four low-powered guard beams. When interrupted, the guard beams act as a circuit breaker, immediately switching off of the central beam and preventing any harm to the obstructing object/person.

“The guard beams are able to act faster than our quickest motions because those beams are reflected back to the emitter at the speed of light,” says Gollakota,

“As a result, when the guard beam is interrupted by the movement of a person, the emitter detects this within a fraction of a second and deploys a shutter to block the charging beam before the person can come in contact with it.”

3D printed security features

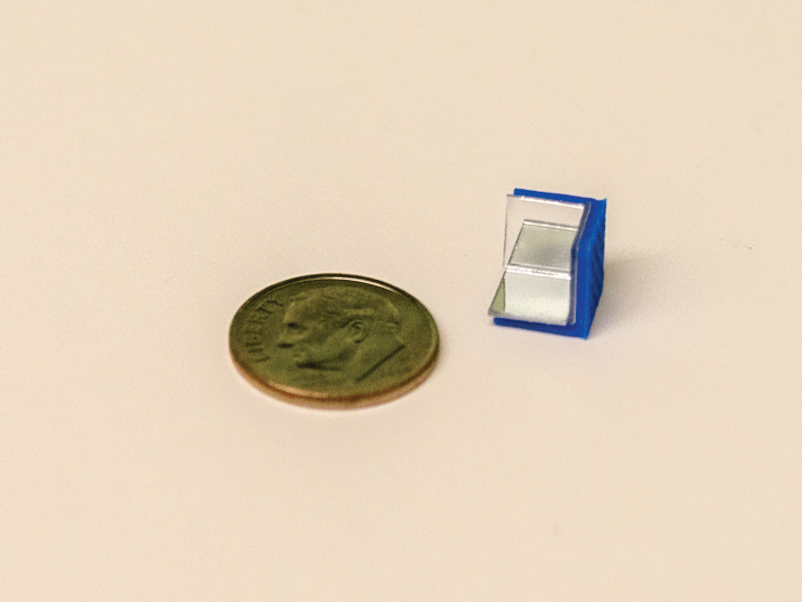

In this early prototype of the device, 3D printing is essential to the beam charger’s in-built security system. Retroreflectors responsible for relaying guard beams between the phone and the laser system were custom 3D printed out of ABS.

The researchers also created a heatsink pad for the back of a phone to displace and excess heat generated by the laser power. To shield users from the high temperature of the heatsink, the team also custom 3D printed an ABS protection case, covered with an insulating layer of kapton tape.

The future – no wires attached

UW experiments have proved that it is possible to charge a phone using a laser across a distance of up to 4.3 meters (approx. 14 feet). By widening the beam’s radius from the typical 15 square-inch to 100 square centimeters, they can also achieve a charging distance of 12 meters (almost 40 feet), allowing plenty of space for wireless charging across a room.

Elyas Bayati, UW doctoral student and co-lead author of the supporting paper on the wireless laser charger, comments,

“The beam delivers charge as quickly as plugging in your smartphone to a USB port, but instead of plugging your phone in, you simply place it on a table.”

Another team at UW have been exploring wireless transmissions applications in their Printed Wifi project. Such research also presents potential advances in the lucrative field of sensors that, 3D printed, have been used to as fire warnings, and the development of wearable tech.

Feeling inspired to design? Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your entries now with the chance of winning a 3D printer.

To stay up to date with research progress subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows the wireless phone charging system powered by lasers. Photo by Mark Stone/University of Washington