While I was at the AeroDef conference last week, I spoke with Dr. Ron Ott, Deputy Director of Energy & Transportation Science at Oak Ridge National Laboratory (ORNL), who told me that Oak Ridge had partnered with a company called Cincinnati Incorporated to retrofit their large gantry laser-cutters with 3D printer extruders. Dr. Ott explained that the new heads would yield a giant FDM-style 3D printer to produce car parts for Local Motors 3D-printed car project. What Dr. Ott failed to mention was that the Cincinnati Inc. machines were going to be ultra fast, too.

After signing an agreement with Cincinnati Inc., the US Department of Energy’s ORNL will help the Ohio-based company to commercialize a large-scale additive manufacturing process that may be 200-500 times faster than current 3D printing methods, while producing parts that are up to 10 times larger (bigger than one cubic meter) in size. ORNL’s group leader in manufacturing systems research, Dr. Lonnie Love, told Forbes how they intend to speed up the print process:

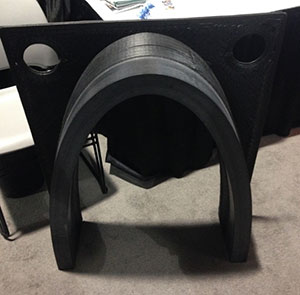

The current ORNL-Cincinnati project draws on expertise gained from a collaboration in large-area additive manufacturing between Lockheed Martin and ORNL, which began in December 2012. The system leverages the injection molding industry. First, the feedstock is pellets so you’re going directly from pellets to parts (rather than a filament). Second, the extruder has a large nozzle (approximately 0.3” in diameter rather than 0.020”).

The larger nozzle enables a few important things. First, you obviously put down a lot more material faster (two to three orders of magnitude). Second, it enables the extrusion of fiber reinforced material. The fiber reinforcement changes the behavior of the material and enables growing it out of the oven. So the larger nozzle speeds it up but introduces much larger layer stratification (poorer surface finish). However, since it’s out of the oven, we can put a spindle on the same machine and “machine it as we go” to get extremely good surface finish while also providing very high deposition rates.”

The project begins with the retrofitting of Cincinnati’s laser cutting system and will be followed by the integration of a high-speed cutting tool, a pellet feed mechanism, and control software. Terry Wohlers, AM expert behind the Wohlers Report, tells Forbes, “The Manufacturing Demonstration Facility at ORNL has been able to pull it off due to its creative, out-of-the-box thinking, coupled with a willingness to invest in a new concept. I know these guys well and I can say without reservation that they are very bright and ambitious.”

Cincinnati Inc. is an experienced manufacturer, producing machine tools since 1898 and shipping more than 31,000 units over that time. The company has also been working with ORNL for a long time, with Cincinnati CEO Andrew Jamison, saying, “Cincinnati Incorporated has enjoyed a long working relationship with Oak Ridge National Laboratory. Over the years we have supplied over 40 metalworking machine tools to Oak Ridge and its various subcontractors. As one of the oldest U.S. machine tool manufacturers, with continuous operation since 1898, we view this exciting opportunity as starting a new chapter in our history of serving U.S. manufacturing. Out of this developmental partnership with ORNL, CINCINNATI intends to lead the world in big area additive manufacturing machinery for both prototyping and production.”

By partnering with the Department of Energy’s ORNL, the company is evidence of the growing public-private partnerships taking place as the result of US taxpayer dollars. The Energy Department’s Assistant Secretary for Energy Efficiency and Renewable Energy, David Danielson, explains, in announcing the partnership, how the project may ultimately benefit those in the US, “The Energy Department and its national labs are forging partnerships with the private sector to strengthen advanced manufacturing, foster innovation, and create clean energy jobs for the growing middle class. Developing innovative manufacturing technologies in America will help ensure that the manufacturing jobs of tomorrow are created here in the United States, putting people to work and building a clean energy economy.”

Dr. Ott discussed with me how the project relates to the DoE’s greater endeavour to reduce greenhouse gasses and fight back the effects of climate change. By reducing the weight of vehicles in the short term, they’d use less fossil fuels and, so, put less pollution into the air. At the same time, other projects at ORNL and the DoE would work to produce better energy storage systems for electric vehicles in the long term. I hope that the doctor’s right and that the technology brought about by the new partnership is actually passed onto those that paid for it.

Source: Forbes