Today in Sliced, 3D Printing Industry’s news digest, we ask: how sharp can you make a 3D printed knife? Is it possible to 3D print PEEK in space? What’s new in metal additive manufacturing? And, where can you get a 3D printed watch?

Read on for all the latest developments from the University of Sheffield, Hasso-Plattner Institute, Rocket Lab, Agile Space Propulsion, Betatype, Senvol, the European Space Agency, Makers Empire and more.

3D printed knives, rockets and bottle recycling

Taking a leaf out of one of our favorite YouTube channels (kiwami japan) a Sheffield knife maker has used additive manufacturing to craft a chef’s knife. Partnered with the University of Sheffield‘s Advanced Manufacturing Research Centre (AMRC) Stuart Mitchell made the knife from titanium and compared the blade to his traditionally made utensils. Commenting on its performance, Mitchell said, “I was impressed by the profile of the blade – it replicated very well what I would do by hand, particularly the taper from the spine to the edge,”

“It did need a degree of grinding to apply an actual cutting edge but the tolerances of the edge were good to start with, very fine. I didn’t realize it would print that fine.”

Researchers at the Hasso-Plattner Institute in Germany, have published a new paper that leverages desktop 3D printing to produce large structures. Titled TrussFormer, the paper expands on previous research from the institute that uses 3D printed connectors to build structures from waste plastic bottles. Now, the TrussFormer project adds 3D printed hinges, allowing moving, kinetic structures.

Demonstration of design for TrussFormer structures. Image via Hasso-Plattner Institute

U.S. commercial aerospace company Rocket Lab, makers of the 3D printed Rutherford engine, has opened a new high-volume rocket production facility in Auckland, New Zealand. According to the company, with more than 4.5 acres of production space it will now be able to manufacture one Electron rocket per week.

Elsewhere in aerospace a new company, Agile Space Propulsion based in Colorado, has said it will be using 3D printing to make thrusters for its affordable spacecraft propulsion systems.

And the 3D printed bridge from MX3D made an appearance this week, not on Amsterdam’s canals (as promised) but in Eindhoven for Dutch Design Week.

Additive manufacturing design and software developer Betatype has worked with luxury watch brand Uniform Wares. The PreciDrive M-Line watch collection features straps produced via laser powder bed fusion assured for performance by Betatype.

Senvol partners with Defense Logistics Agency

Following its $100 thousand grant from the U.S. National Institute of Standards and Technology (NIST) for materials characterization, additive manufacturing database Senvol has been awarded money to conduct a project for the U.S. Defense Logistics Agency (DLA). Together Senvol and the DLA will work on a project title “Additive Manufacturing Sensor Fusion Technologies for Process Monitoring and Control.” The news also follows Senvol’s recent induction into the National Armaments Consortium.

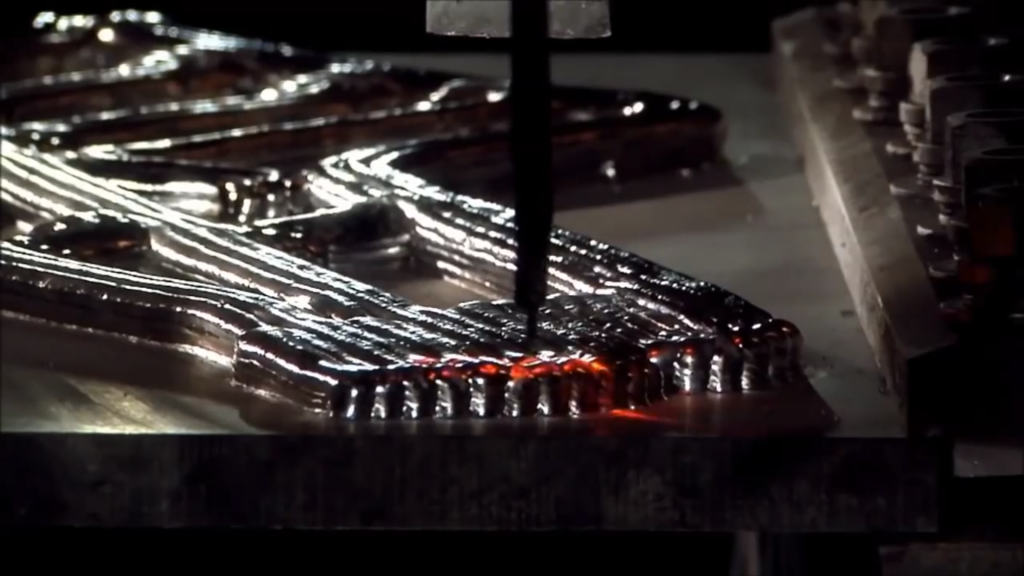

The European Space Agency‘s (ESA) Project MELT (Manufacturing of Experimental Layer Technology) 3D printer has received an update after exiting stealth mode earlier this year. The system, designed to work with high performance thermoplastics in low-gravity conditions, can be seen operating in a new project video from MELT consortium developer BEEVERYCREATIVE (clip below).

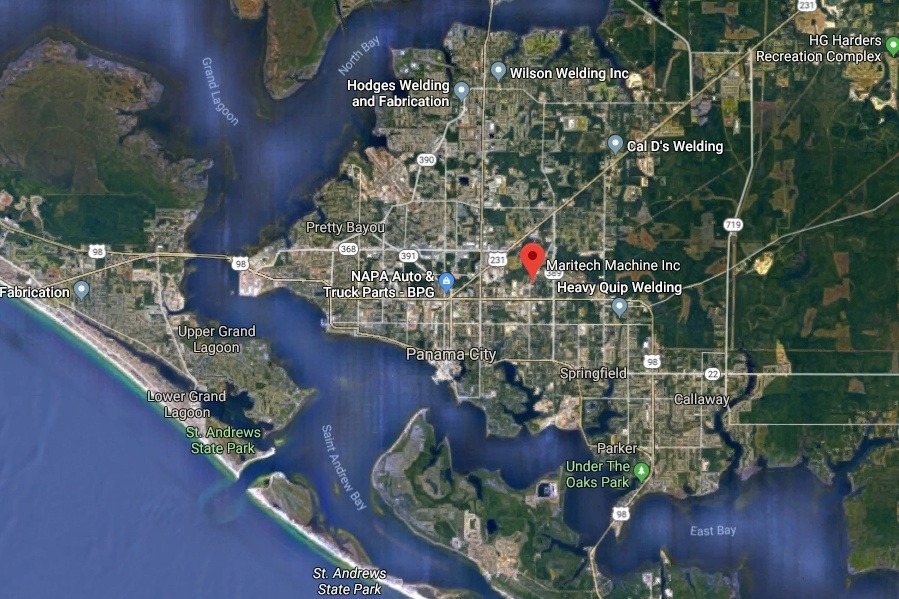

Xometry launches GoFundMe aid in wake of Hurricane Michael

Expanding its existing partnership with Dutch metal 3D printer manufacturer Additive Industries, the Alfa Romeo Sauber F1 Team has acquired its third MetalFAB1 system from the company.

U.S. software company Accucode has become a North America reseller for PCB 3D printer provider Nano Dimension. Tim Sheehan, Vice President Sales Nano Dimension, comments, “Since the launch of DragonFly Pro sales a year ago, we’ve learned much about where our relative strengths and value proposition fit within the North American marketplace, as well as the expertise our resellers need. We look forward to making more announcements of this kind in the near future.”

Maryland-based on-demand manufacturing platform Xometry has launched a GoFundMe campaign to raise $5,000 for its Manufacturing Network Partner, Maritech Machine Inc. Maritech Machine’s shop was severely impacted as Hurricane Michael swept across Panama City in Florida last week. Contribute to the fund and help them get back on track here.

Makers Empire has launched a new partnership to roll out 3D printers, design software and lesson plans to over 200 UAE primary schools throughout 2019.

Document printer reseller KYOCERA has become the official distributor of Leapfrog 3D printers in New Zealand and Australia.

And UAE consumer electronics company Jumbo Group has launched Jumbo 3D Manufacturing to create a 3D printing community of service bureaus, and partners, that already includes EnvisionTEC and HP.

LAR launched sub-$70,000 metal 3D printer

Russian 3D printer manufacturer LAR Technologies has launched a metal additive manufacturing system for €69,900 ($80,218). The “affordable” price tag has been set for a limited time only, and comes with the caveat of paying extra for “add ons” such as a powder recycling system (€12,500, $14,345) and a two-way coating system (€4,900, $5,623).

A “prominent Southeast Asian aerospace parts manufacturer” has reportedly ordered a hybrid EBAM and EB Welding System from industrial 3D metal printing provider Sciaky Inc.

No-melt metal 3D printing technology from Virginia’s MELD Manufacturing has won first place in Society of Automotive Engineers International‘s (SAE) 2018 Create the Future Design Contest.

For all the latest medical, business, applications, materials and hardware news subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook. Create a free profile on 3D Printing Jobs, or advertise to find expertise in your area.

Featured image shows Sliced logo over a structure made using the TrussFormer platform. Original photo via Hasso-Plattner Institute