This edition of our 3D printing news digest Sliced follows the latest innovations from BigRep; 3D printed motorcycles and the escape from Alcatraz. Featured stories include Protolabs, FIT, Energica, Samsung Electronics Italia, BMW Group, BigRep, Swinburne University of Technology, and more.

Escape from Alcatraz 3D printed decoy heads

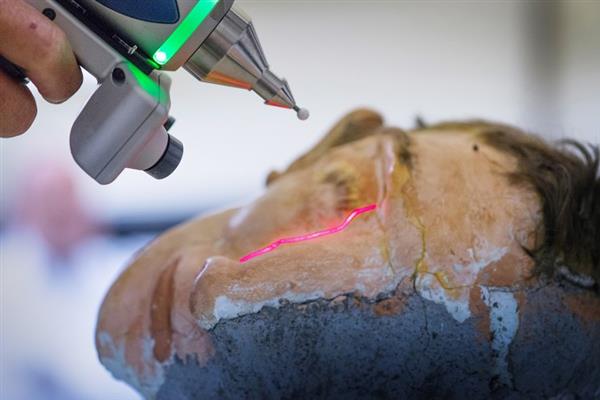

The FBI San Francisco Division has presented the Golden Gate National Recreation Area (GGNRA) with 3D printed replicas of the decoy heads used by prisoners in the infamous 1962 escape from Alcatraz Island.

The GGNRA, part of the U.S. National Park Service (NPS), collaborated with the FBI to preserve and recreate the original heads of Frank Morris, Allen Clayton West, and John and Clarence Anglin to educate the public on the history of the former federal penitentiary. The FBI team scanned the original heads made from toilet paper, cardboard, cement chips, and human hair, which were used to distract prison guards. The 3D models constructed from the scanned data was then used to print the replicas. These models were then painted to resemble the originals.

“None of the escapees have ever been located, but the United States Marshals Service continues to investigate any and all credible leads,” said Don O’Keefe of the United States Marshals Service.

“Some may believe that we’re chasing shadows, but our efforts are meant not just to perform due diligence, but to be a warning to other fugitives that U.S. Marshals don’t give up because of the passing of time.”

3D printing to make buildings less boring

Professor Jay Sanjayan, Director of Swinburne University of Technology’s Centre for Sustainable Infrastructure has shared his thoughts on the impact of 3D printing in construction. “While agriculture and manufacturing have increased productivity 10-15 times since the 1950s, construction remains stuck at the same level as 80 years ago,” says Professor Sanjayan in an article for Pace Today.

“That’s because construction remains largely manual, while manufacturing and other industries have made significant progress in the use of digital, sensing and automation technologies.”

“We and other research groups see 3D printed concrete as a possible solution to these problems. The technique will likely also give architects the freedom to inject more creativity into their designs for new structures.”

From the appearance of some 3D printed buildings too, we can’t help but agree with his point of view.

BMW announces 1 million 3D printed parts

In automotive the BMW Group reported that it has produced approximately one million 3D printed parts over the last decade. BMW Group Additive Manufacturing Center is also expected to reach more than 200,000 components—a 42% increase over last year’s total.

Prodrive, a UK based motorsport and advanced technology company, is supplying additively manufactured carbon fiber composite components to Overfinch, the creator of bespoke Land Rover vehicles, to optimize its supply chain. Kevin Sloane, Chairman of Overfinch said:

“Our partnership with Prodrive has enabled us to significantly increase production and move into new markets. Prodrive collaborates with us on an ongoing basis including design work, product revisions, and production.”

“It can deliver fixed volumes each week to match our build order and provide components that are significantly easier to install than those we were using in the past.”

And finally Energica, the manufacturer of the Energica Ego – Italy’s first street-legal electric motorcycle with 3D printed parts – and Samsung Electronics Italia have unveiled the Bolid-E at EICMA motorcycle show in Milan earlier this month.

As part of the Samsung Electronics Italia and Energica’s Smart Ride Project, the Bolid-E motorcycle includes 3D printed components such as front and back headlights and tail light supports, from CRP Technology’s line of Windform composite materials.

New 3D printer orders

INTECH, an India-based developer of 3D printing software, has confirmed its first order of the Additive Industries MetalFAB1 system.

“Accelerating adoption of additive manufacturing is the primary objective at Intech. Moving from prototyping to series production with focus on cost per part with repeatable quality is the way forward,” said Sridhar Balaram, CEO of INTECH.

3D Systems has announced that FIT Additive Manufacturing Group, has installed three ProX 800 3D printers and one ProX 950 SLA 3D printer at its facilities in Lupburg, Germany. “We consider 3D Systems SLA solutions to be the gold standard in 3D printing for precision, reliability, and material properties – critical factors to meet our customers’ high manufacturing standards,” said Carl Fruth, CEO, FIT.

“We are using the Accura ClearVue to produce transparent skull models that help surgeons prepare for cranial neurosurgery. Other applications include 3D printed automotive parts to test aerodynamics in wind tunnels; durable product prototypes for evaluating fit, form, and function; and precision master patterns for vacuum casting.”

Metal, polymer and biomaterials

Dimension Inx, a Chicago-based materials company, has signed a distribution agreement with Advanced Solutions Life Sciences (ASLS), a 3D bioprinting company based in Louisville, Kentucky. Through this partnership, ASLS will offer Dimension Inx’s bioprinting materials to clients worldwide; this includes 3D printable inks such as Hyperelastic Bone, 3D Graphene and 3D Graphite.

In other news, researchers from the Wong Lab, Brown University are studying the early spread and behavior of cancer cells using 3D printed hydrogels from synthetic polymers. The main aim of this research is to innovate medical practices in the field of oncology.

As part of the Small Innovative Launcher for Europe (SMILE) project, researchers from the German Aerospace Center Deutsches Zentrum fur Luft- und Raumfahrt (DLR) have developed a reusable rocket satellite engine using metal 3D printing.

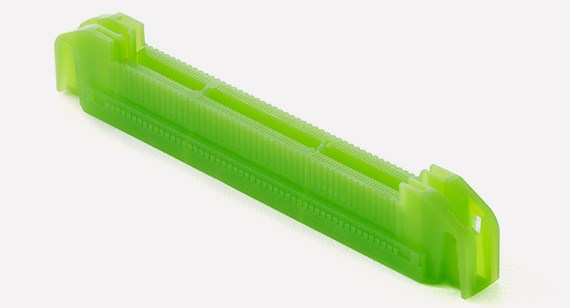

And Protolabs, an award-winning on-demand manufacturing provider, has introduced its proprietary thermoset resin, MicroFine Green, which builds parts in 0.025mm layers.

For the latest additive manufacturing news, subscribe to the 3D Printing Industry newsletter. Also, find us on Facebook and like us on Twitter.

Looking for a career change? Search and post new opportunities across additive manufacturing by visiting 3D Printing Jobs.

Featured image shows the Sliced logo over the Samsung Electronics Italia and Energica Bolid-E motorcycle. Original photo via Energica.