3D printing is making leaps and bounds in its advancement, and through its journey forwards, this technology is taking many other technologies and applications forward along the way. As part of a series of articles, in this particular instalment, we look at the importance of 3D printed mockups of human organs in the development of new medical techniques.

As mentioned in a previous article in the series, accurate models are becoming more and more important for training, surgery rehearsal and designing new tools that improve current methods for medical treatments. This isn’t just as real, touchable models either. Virtual Reality (VR) is one avenue in the field of training and development, though the best way of putting ideas into practice is through a hands-on approach. This is made possible through various methods, though 3D printing has been rising to the challenge in recent years.

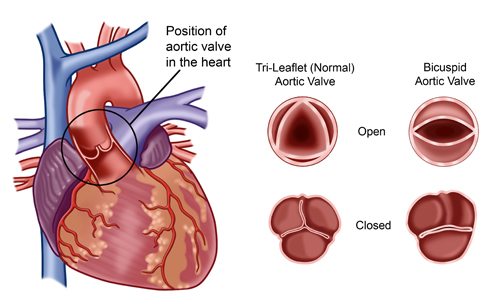

One example of this is through the development of technology for Cognitive Catheters Operating in Dynamic Environments (CASCADE). They have been recently developing the method for Transcatheter Aortic Valve Implantation (TAVI), which is a complex and difficult procedure. Normal catheters would be fed through the arteries to reach the valve and install the replacement implant.

The downsides to this are various risks. There are limited ways of viewing the catheter as it made its way through the arteries, making it hard to realise if there was a problem due to limited angles the catheter could be viewed at. Another risk that if the catheter was pushed too hard against the wall of an artery, the catheter could rupture it or even knock off build up material that is stuck to the walls.

From here, the team behind CASCADE set out to develop a smart catheter that is easy to track. Whilst carrying out testing for this, they used a combination of virtual and 3D printed models. The 3D printed models allowed the team to used their joy-stick controlled prototype to identify any problems with it and resolve them. Many models they used however, were printed in a rigid material. This isn’t as accurate as the real thing since the material doesn’t really mimic the tissue of the aorta or arteries, but it does give a good idea of how the smart catheter would navigate around thin tubing with as little risk of damage as possible.

This ‘self-aware’ catheter has also been fitted with sensors to not only create its own ‘cruise control’ system, but also scan the artery via ultrasound as it passes through, creating an accurate model of the patient’s arteries and aorta. From this data, the catheter then works out the midpoint of the artery, and follows the midpoint as a guide. It is hoped this will avoid colliding with the walls of the arteries, avoiding the possibility of ruptured arteries and dislodging calcified deposits and other build ups.

There is even the possibility of using the data to help create an accurate model of a patients aorta, which could help with rehearsal the TAVI procedure if the model is printed or used as a VR model. The progress of development for this particular application can only grow and improve.