In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features the latest supply chain updates, Additive Manufacturing (AM) partnerships, 3D printing materials, industry investments, and even the inaugural AM Olympics.

Read on for the most recent updates from voxeljet, Nanofabrica, CDG, 3D Chimera, OPEN MIND, the ESA, and more.

3D software updates from Jellypipe, MakerOS, and OPEN MIND

Starting with this week’s software launches, Switzerland-based 3D printing company Jellypipe has expanded its range of online services. The software firm has extended its platform so that it will now offer its European 3D printing B2B professional online ecosystem in both the UK and Ireland as well. Jellypipe’s platform aims to provide users with any consultation needed to ensure that they optimize their use of AM.

Jellypipe users upload 3D files to their chosen solutions provider and the rest of the process is automatic. The provider can liaise with the customer before putting the job out to manufacturers for quotes, and clients can decide which package of speed and cost suits their needs.

“Users of Jellypipe can easily access a huge resource of knowledge, advice, and consultation to ensure that the correct materials, 3D printing technology, and finishing is selected,” said Georges Benz, President, and Co-Founder of Jellypipe. “It really couldn’t be more powerful or more simple to engage.”

Web-based 3D printing company MakerOS has released the latest version of its collaboration software. The program makes it easier for digital fabrication teams to work with each other by providing an updated automated quoting system, CAD file viewer, client portal, and project board system. New updates to the revamped communication hub, project boards, and client portal have also been added to provide greater integration.

Using the messaging feature within the hub, companies can now take advantage of a bespoke emailing system that is specifically designed to cover particular projects. MakerOS has also integrated an upgraded online 3D viewing and inspection tool. The update is designed to create an all-in-one project management to client experience, without needing to leave the software.

John Kray, Founder, and CEO of Portland-based Hydra Research said: “MakerOS has really streamlined our project management for our 3D services. The biggest benefit we have seen is the ability to have all communication, CAD/reference files, and invoices accessible in one easy to use online portal. This is miles better than having all this information scattered through multiple email threads with our clients.”

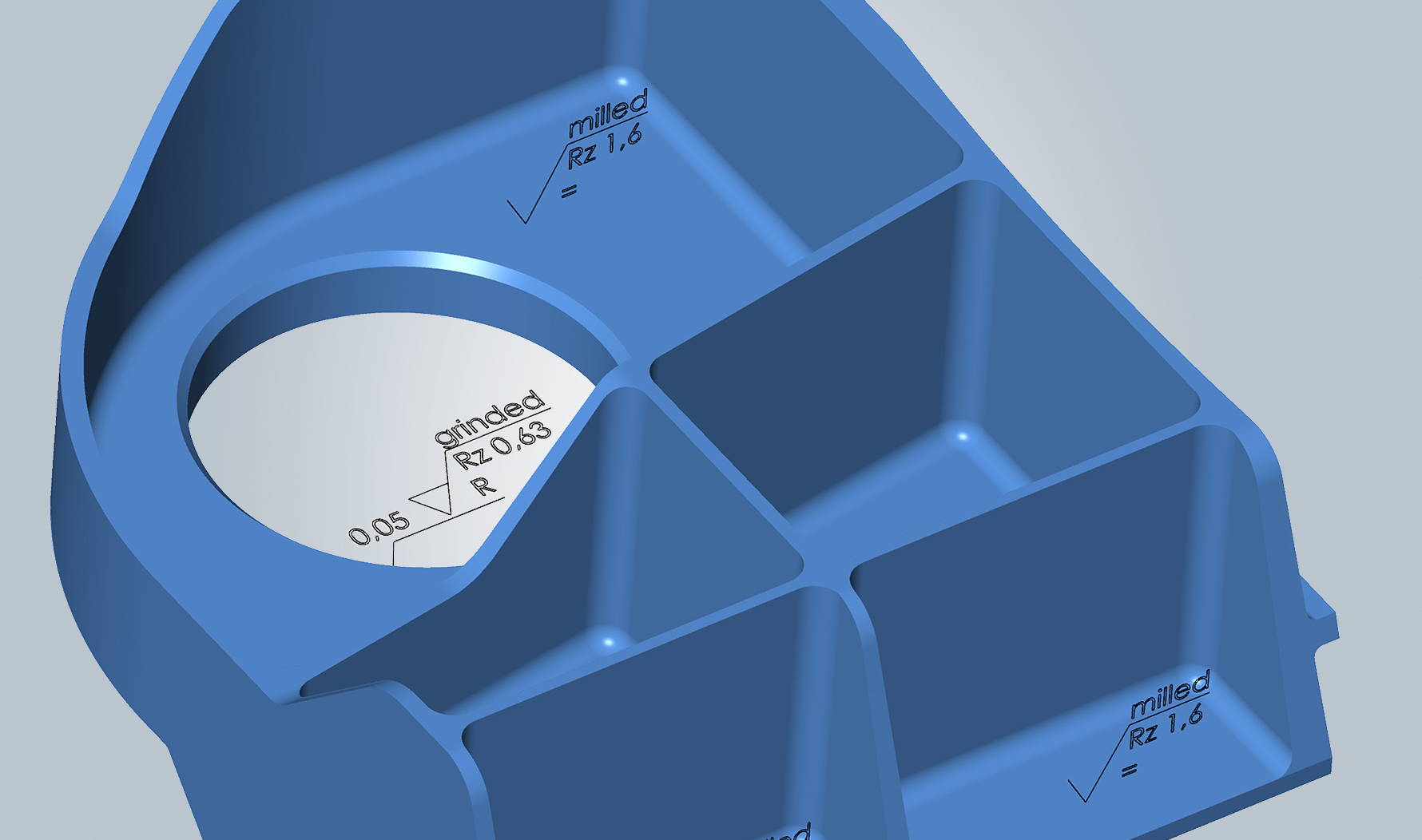

The developers of CAM software solutions OPEN MIND and Tech Soft 3D have announced that the HOOPS Exchange program will be integrated into their systems. By introducing the software into their platforms, the firms ensure that all CAD data can be efficiently transferred between their hyperCAD®-S and hyperMILL applications.

Lionel Vieilly, Product Manager at Tech Soft 3D said that providing access to data with low memory usage is paramount when building sophisticated 3D applications. What’s more, the CAM software provides advanced technology geometry analysis and tool path calculations, that are designed for the efficient programming and machining of components

“Tech Soft 3D is a trusted, reliable development partner who helps us implement specific requirements and accommodate customer requests,” said Dr Josef Koch, CTO at OPEN MIND Technologies. “This kind of responsiveness is critical in our industry, as well as interoperability with multiple CAD formats.”

New partnerships for Unispectral, CDG, voxeljet, and SLM Solutions

Samsung-backed company technology developer Unispectral has deployed Nanofabrica’s microscale 3D printing solutions to produce a range of low-cost tunable Near Infrared (NIR) filters. Unispectral’s cost-effective products add a biometric layer to camera verification systems, leading to improved facial authentication and camera-based material detection.

Due to the level of precision required to produce the devices, Unispectral previously used injection molding to fabricate them in great quantities. Switching to Nanofabrica’s micro 3D printing technology has allowed for the adapter to be redesigned for different brands of mobile phone, without the need for expensive tooling. Any design tweaks can be made in the CAD model downloaded to the 3D printer, reportedly making mass-customization possible.

“In the mobile phone market, we have very rapid changes each year, so we need to adapt quickly, iterate, adjust the design, and with the help of Nanofabrica’s technology, we are able to adapt rapidly to various camera model designs,” said Peleg Levin, CTO of Unispectral.

UK-based 3D printer provider Concurrent Design Group (CDG), has invested in a 3D Systems Figure-4 Modular DLP 3D printer. The new machine can be connected to between 1 and 24 other units, to increase production volumes in line with demand. Each printer can run a separate material, such as performance plastics, rubber and biocompatible, and silicone can also be used via an eggshell mold.

The system enables CDG to use Digital Molding (DM), which reportedly makes high-quality batch production possible, without the need for complicated tooling. A total of 1,300 parts were 3D printed in four hours during CDG’s first print job, which is equivalent to five parts per minute. When deployed in series manufacturing applications, the Figure-4 is reportedly able to print more than 10,000 parts per month in production materials.

German metal 3D printer manufacturer voxeljet has secured another sale of its industrial 3D printer, the VX4000 in one of the largest foundries in India. Indian steel casting company, Peekay Steels’ acquisition was in-line with the Indian government’s new ‘Make in India’ initiative. The program aims to take on international and domestic businesses, and it’s hoped that the VX4000 will go some way to achieving this.

“In the last couple of years, the government of India has pushed its ‘Make in India’ initiative, thereby encouraging businesses to invest into the future,” said , Managing Director voxeljet India. “For our customers in India, it was clear that adopting new technologies would help them benchmark against international standards and fuel growth.”

Brazil-based orthopaedic implant manufacturer Sartori has acquired an SLM 280 system from metal 3D printer manufacturer SLM Solutions. Using its new machine, Sartori aims to expand the use of 3D printing within the healthcare sector in Brazil, and to take advantage of the expected growth there.

Selective Laser Melting (SLM) 3D printing also allows for the integration of functional elements such as porous structures to surgical implants which are used for anchoring artificial limbs on the human skeleton.

As a result, Sartori’s new system will enable it to better cater for the needs of its clients and surgeons with a more varied range of surgical implants. The company is also working closely with national and international regulatory authorities such as Agência Nacional de Vigilância Sanitária (ANVISA) in order to qualify machines for medical production.

“Additive Manufacturing gives us the possibility to provide implants and instruments with functional integration that enable improved surgical outcomes, improving patients’ lives,” said Luiz Guilherme Sartori, CEO of Sartori. “We decided to work with SLM machines because they provide process safety due to the closed-loop powder handling and have a sintered wall in the process chamber that improves gas flow and part quality.”

New 3D printing applications with 3DChimera, U.S Air Force and OPENMIND

Industrial 3D printer provider 3DChimera has become the only Florida-based company to compete in the U.S Air Force’s inaugural Advanced Manufacturing Olympics. The four-day virtual event scheduled for October 2020, will see participants including universities, contractors, start-ups and companies compete in five categories, for a cash prize of $40,000. 3DChimera will take part in two categories; the Technical Data Package (TDP) Relay and the Approval Sprints.

The TDP Relay challenges teams to accurately recreate a 3D printed part from an existing TDP. Approval Sprints meanwhile, challenge the teams to apply innovative methods to accelerate Government approval timelines by identifying creative qualification strategies for new materials, machines, and components. Winners of the competition will be announced during the event which will be held from October 20nd-23rd 2020. Registration is open on the U.S Air Force website and is free to the event to attend.

“We are all engineers by training and have spent nearly a decade acquiring deep technical expertise in advanced manufacturing, from the design, software, 3D printers, to materials,” said Alex Hussain, CEO of 3DChimera. “The fact that the U.S. Air Force is investing in this competition confirms that advanced manufacturing is best used to solve complex and intricate problems.”

The Australian Army’s 3D printed gunner’s ratchet

The Australian Army has carried out a second set of field exercises using SPEE3D’s WARPSPEE3D additive manufacturing systems. During the trial, the soldiers 3D printed a gunner’s ratchet, which they currently use in the service of M242 Australian Light Armoured Vehicle Machine Gun. While sourcing the tool using existing supply chains would cost significant time and money to obtain, the trial demonstrated that the ratchet can be easily replaced on-demand. The 1CSSB design was fabricated by the squad in under an hour, and the material used reportedly cost less than $100.

“Custom made parts, designed and printed in the field, means we can provide the mechanism for our people to get equipment back into action quickly and return it to its primary role on the battlefield,” said Lieutenant Colonel Wright. “It was great to see the team working together to think of new ways to use the 3D printer, it demonstrated the many hidden talents Australian soldiers possess.”

Penn State, DryLite raise additional funding

Penn State researchers have raised $546,806 in funding from the National Science Foundation. The investment will be used to fund a project which aims to create an improved and more cost-effective method of 3D printing complex metal components. During the three-year program, Qian Wang, professor and the principal investigator of the program, aims to develop new models for Laser Powder Bed Fusion (LPBF) 3D printing process. Although LPBF enables the creation of metal parts such as those used to repair ships, the process is expensive, time-consuming and can often result in a flawed final component.

To avoid this, a numerical model called finite elements can be used to computationally enhance the design, but this takes time, resources and is difficult to adjust to real-time. Wang will attempt to capture the essential physics of the process with a significantly reduced computational complexity, as compared to finite element models.

“This grant will enable a manufacturing process for high-value components with complex geometries that have many different applications,” said Wang.“The overall objective will be to improve the part quality and consistency, which will help increase the economic competitiveness of metal additive manufacturing.”

Germany- based dental products specialist TEAMZIEREIS has invested in a dry electropolishing system called DryLite. The system allows the automatic polishing of components produced using hybrid manufacturing such as removable partials, dental crowns and products for orthodontic treatments.

During the polishing operation, the workpieces which have been mounted to set fixtures, pass through the electrolyte in a rotary movement. This causes an ion exchange between the workpiece and electrolyte which eliminates roughness from peaking on the entire surface including internal passages. Ralph Ziereis, who founded TEAMZIEREIS’ 20 years ago, shared how he found the dry electropolishing system: “A customer told us about the innovative DLyte polishing method. Subsequently we informed ourselves about this technology and its possibilities at the AM Solutions booth during the 2019 formnext show,” he said.

ESA releases STL files for 3D printed mars rover

The European Space Agency (ESA) has made the STL files for 3D printing a miniature Mars rover publicly available online. The tiny bot which runs on a Raspberry pi, is based on the ESA’s Rosalind Franklin rover which was scheduled to go to Mars this year. Despite the delays caused to the mission by COVID-19, hobbyists can now launch their own ExoMy missions from the comfort of their own home.

The ExoMy features a triple bogie suspension design that breaks with the layout seen in NASA JPL’s rover designs. With the instructions posted on GitHub users can build the device’s remote-compatible software stack and recreate its Robot Operating System (ROS). The ExMy is reportedly possible to build for between $295 and $590.

What companies do you think are leading the 3D printing industry? Let us know by nominating them for the 2020 3D printing Industry Awards.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway! Enter your design for your chance to win a CraftBot Flow 3D printer.

Check us out on Twitter and Facebook for more updates! Don’t forget to subscribe to the 3D Printing Industry newsletter and keep up-to-date with the latest 3D printing news.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the additive manufacturing industry.

Featured image shows the Sliced logo on a 3D printed cartoon. Photo via MakerOS.