In this edition of Sliced, the 3D Printing Industry news digest, we cover the most recent partnerships, innovations, and business updates across our industry.

Today’s edition features new additive manufacturing partnerships, a 3D printer leasing service, new printers and materials, and recent awards for 3D printing biodegradable sneakers.

Read on for the latest updates from DMC, PostProcess Technologies, Advanced Laser Material, NCS Technologies, Sigma Labs, and more.

3D printing partnerships from DMC, Renishaw, Post Process Technologies and BV Products, BASF, Roboze

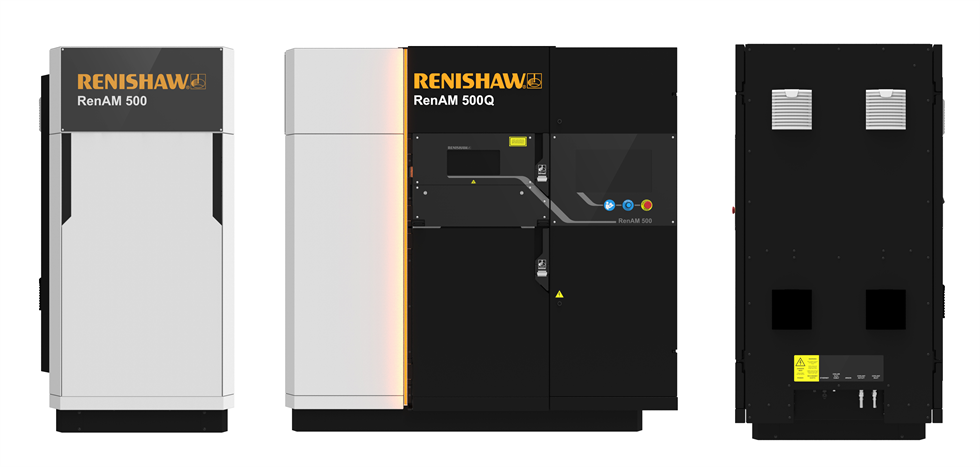

The UK-based Digital Manufacturing Center (DMC) and global engineering technologies company Renishaw have announced a joint development collaboration. Their partnership was marked by DMC’s first purchase of two RenAM 500Q machines from Renishaw. This purchase will allow DMC to offer end-to-end products with reduced weight, costs, and increased quality.

“The decision to forge a close collaboration with Renishaw and purchase two RenAM500Q machines was a natural step,” said Kieron Salter, CEO of DMC. “Its machines offer unrivaled productivity, quality control, and ability to create a light component but with high strength – one of the key benefits of metal AM innovations.”

PostProcess Technologies, an automated post-printing developer, has signed an agreement with Australian-based manufacturer BV Products. As both companies specialize in the finishing industry, this partnership will allow PostProcess Technologies to expand its market in another continent while simultaneously allowing BV Products to expand in aerospace, automotive, medical, and military sectors.

“We could not be more confident in our choice of BV Products to usher in the transformative power of PostProcess’ intelligent solutions to the Australian market,” said Bruno Bourguet, Managing Director at PostProcess Technologies International.

Global chemical producer BASF, and Advanced Laser Material (ALM), a subsidiary of EOS, have signed a distribution agreement for ALM to deliver three Polyamide 6 (PA6) materials, including Ultrasint PA6 FR, Ultrasint PA6 MF, and Ultrasint PA6 LM. Also, one polypropylene (PP) material, Ultrasint PP nat 01, will be delivered to BASF. The combination of ALM’s EOS INTERGRA P450 machine and BASF’s versatile CAE competence simulation software will allow the companies to explore new applications with the material.

“Forward AM’s Ultrasint Polypropylene is fully weldable, and its translucency and media-tightness make it perfect for tanks and reservoir prototypes,” said Jeremy Vos, Automotive and Powderbed Manager at BASF. “The ability to leverage high-performance AM materials to do short-run production will open up new opportunities for customers in the automotive industry.”

Italian and US-based 3D printer manufacturer Roboze has partnered with NCS Technologies, a U.S.-based computer designer and manufacturer. Recently, NCS has specialized in 3D printing solutions using metal, composite materials, and super polymers. Roboze’s contribution with the ARGO SERIES 350/500 3D printers will allow NCS to address new markets, including aerospace, industrial and medical.

“We are proud to collaborate with NCS to serve the American defense, aerospace, and medical industries,” said Alessio Lorusso, CEO, and Founder of Roboze. “ARGO SERIES represents a step forward to bring manufacturing back to America, producing extreme end-use parts with the highest performing composites and super polymers, even for metal replacement applications.”

New six-month leasing service by BigRep

BigRep, a German-based large-format 3D printer manufacturer, is offering a 3D printer leasing service for its BigRep STUDIO G2 industrial printer for North American customers. This service was made possible through a partnership with NCP Leasing. The STUDIO G2 standard lease covers six months at a monthly rate of $3,000 plus a nominal fee covering installation and training. Moreover, customers will have access to Big Rep’s industrial applications and a range of high-performance filaments. Once the lease has expired, the customers can either renew their lease, purchase the system, or return the printer.

“For the first time, our service makes a large-format industrial 3D printer available to new customers or small to mid-sized businesses”, said Frank Marangell CBO and President of BigRep America. “Facing a challenging economic environment and volatile markets, customers today want quick and flexible solutions without big investments and long-term obligations.”

New printer from Sigma Labs

Santa-Fe based additive manufacturing software developer Sigma Labs has launched its PrintRite3D Lite In-Process Quality Assurance System printer. Following the launch, Coherent, a powder bed fusion (PBF) system manufacturer, signed a contract with Sigma Labs for the new release because of the machines’ ability to validate thermal models coupled with thermal measurements.

“We are pleased to announce the launch of our new PrintRite 3D Lite product as we begin implementation on the Coherent CREATOR 3D printer.” Said Mark Ruport, President and CEO of Sigma Labs. “PrintRite3D Lite is a great solution for 3D metal printing companies and end-user manufacturers.”

New Materials from Ricoh 3D

Ricoh 3D, the 3D printing subsidiary of Japanese electronics, expanded its 3D printing material portfolio by adding the material PA2200 Nylon 12 for its Selective Laser Sintering (SLS) process. PA2200 Nylon 12 is a common prototyping material that is extremely versatile. This new addition can allow customers to build parts that need large scale models with a higher visual finish. The material is also biocompatible and holds an ISO 13485 certification, which can be used for medical applications.

“PA2200 offers a good balance of mechanical properties and visual qualities. It produces bright white crisp parts that are ideal for projects where high aesthetics are important. The material can also be dyed in-house in a range of primary colors”, said Richard Minifie, Senior Additive Manufacturing Engineer at Ricoh 3D.

Technology: Updates from 3DEO

Los Angeles-based metal 3D printed part provider 3DEO has hit an inflection point in production.

“I am thrilled to share a significant milestone; we hit an inflection point in production last month: 3DEO shipped more than 35,000 parts in one week”, said Matt Sand, President of 3DEO. “3DEO is a digital industrial platform, built around our proprietary metal 3D printers, created specifically to compete with traditional manufacturing on both quality and price.”

Additive manufacturing awards

A non-profit organization, Partnership for Public Service, has announced Dr. Beth Ripley as the Samuel J. Heyman Service winner to America Medal in the Science and Environment category. Ripley is the national director of the VHA 3D Printing Network at the Department of Veteran’s Affairs. She was awarded for creating an interconnected 3D printing network permitting surgeons to examine exact 3D models of their patients’ organs and tissues before carrying out operations.

Ripley explains that with 3D printing, “patients have been able to understand their disease even before they go into surgery. There’s a whole other world where we are 3D printing orthotics, hand braces, and prosthetics for patients to get back to doing the things they love doing.”

In New Zealand, design engineer Rik Olthuis won the national James Dyson Award, run by the James Dyson Foundation Trust, for creating a pair of 3D printed biodegradable trainers. This is an international design award that celebrates the next generation of design engineers. On account of the annual waste created by throwing away clothes and shoes, Olthuis created a shoe without adhesives so that it composts faster.

“It’s a running shoe, but the line is blurred between athletic and casual,” said Olthuis. “The use of adhesives prevents the separation and treatment of materials at the end of the product’s life cycle. I was inspired to design a sneaker using only biodegradable materials with no adhesives.”

Business news from MakerBot

Brooklyn-based additive manufacturer MakerBot released results from its 3D Printing Trends report revealing that 74% of companies plan to invest in 3D printing in 2021. The report is based on the response of 1,200 professionals from the aerospace, industrial, automotive, medical and military, and defense industries. The responses revealed out of the 74% of companies planning to invest, 50% of them wanted to invest up to $100,000.

Nadav Goshen, CEO of MakerBot, said that “while COVID-19 impacted the business operations of nearly 70% of the respondents, 56% said that it did not impact their investment plans in 3D printing. When respondents were asked what their investment plans were for the next year, 74% stated that they still had plans to invest in 3D printing.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows coloured printed parts in Ricoh 3D’s new material, PA2200 Nylon 12. Photo via Ricoh 3D.