In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features automotive and marine 3D printing advances, reseller network expansions, several software updates and an additive manufactured nineteenth century animation device.

Read on for the most recent updates from ROBOZE, PUNCH Torino, Wematter, Braskem, Materialise, Autodesk, B9Creations and more.

Software updates from B9Creations, Autodesk and Materialise

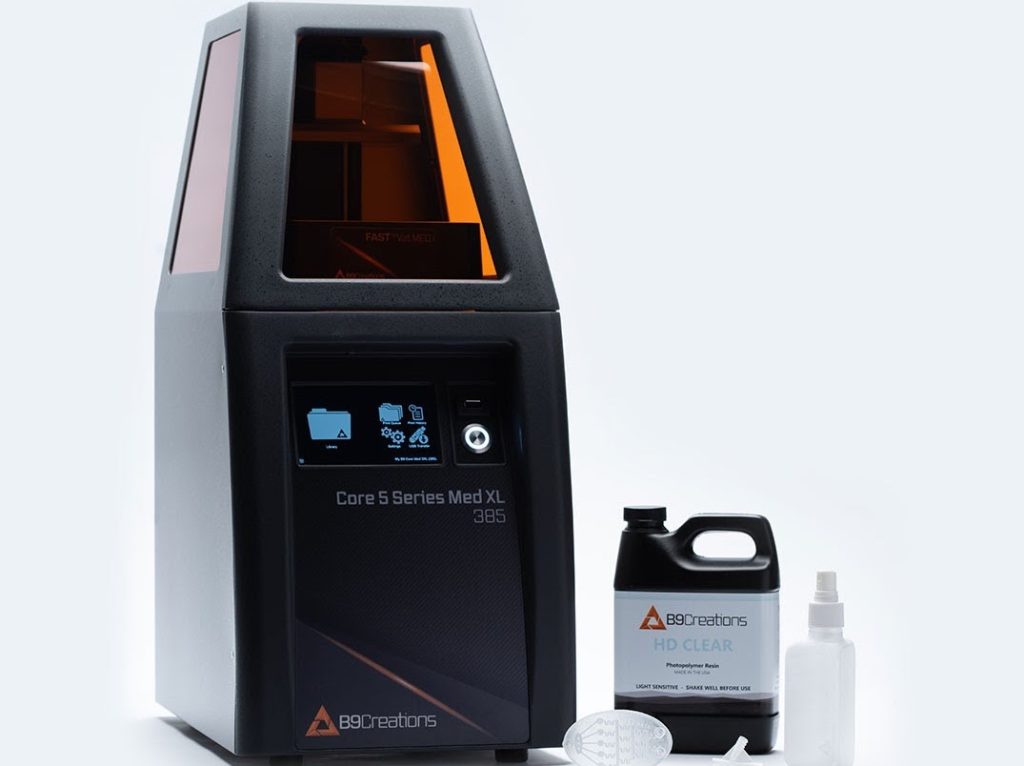

Kicking-off this week’s news digest with B9Creations, the South Dakota-based 3D printer manufacturer has launched an upgraded version of its B9Captivate software. Designed to allow users to create custom settings for their B9 Core Series 3D printers, the material development toolkit now features dark site capabilities, which better protect the privacy of manufacturers’ sensitive production data.

Autodesk has also improved its popular Fusion 360 program, releasing two new Fused Filament Fabrication (FFF) print settings in its September 6, 2022 update. According to Bradley D. Woods, CEO of the Virtual Foundry, the latest version of the software, which brings Bronze and Copper Filamet compatibility, will help “bring bound metal/FFF metal printing further into the mainstream.”

Materialise, meanwhile, has looked externally to improve its software offering, and announced the acquisition of Identify3D.

Having bought the firm, complete with its software products that encrypt, distribute and trace the flow of digital parts, Materialise now plans to add a further security layer to CO-AM. In doing so, the company aims to make it “the most robust and secure software platform for manufacturers that are looking to scale” their use of 3D printing in distributed manufacturing.

“At the center of a digital supply chain is the movement of valuable data from design through manufacturing,” said Joe Inkenbrandt, CEO of Identify3D. “Our mission has always been to address the security and integrity of that data. Integrating our software into the Materialise CO-AM platform allows us to fully unlock its potential and give customers security and control of their data in a way never seen before in the industry.”

Additive manufacturing finds artistic applications

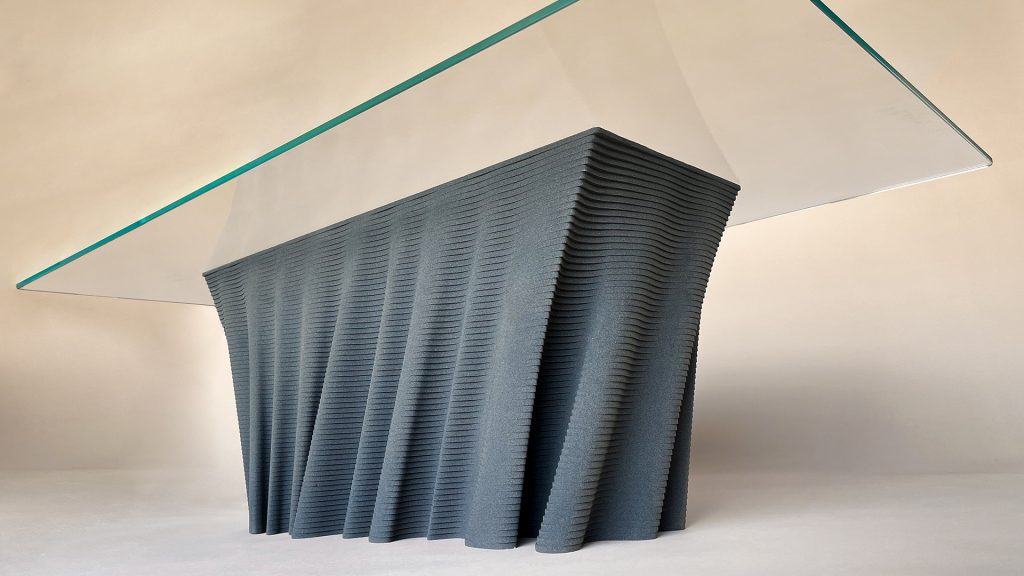

Moving on to the art world now, design studio Duffy London has partnered with German manufacturer Sandhelden to 3D print a ‘Dune’ coffee table. Designed to imitate the wave-like patterns of sweeping sand dunes, the glass-top furniture piece has been made possible by 3D printing with natural feedstock. According to creator Christopher Duffy, realizing the artistic vision behind the table’s free-flowing twists and distortions previously proved difficult to achieve via other technologies.

“Working with Sandhelden, we’ve been able to understand the beauty and versatility of 3D printing with sand,” Duffy told designboom. “Our designs can be twisted on their heads, scaled up, and formed as larger furniture pieces and sculptural forms. It looks alluring, captivates, and feels weighty and tactile to the touch. We are already starting to explore future concepts and special editions, so this is only the beginning.”

Elsewhere, English artist R James Healy has used 3D printing to recreate three ‘zoetrope’ pre-cinema animation devices. Composed of a slotted cylinder containing a series of drawings, often showing people or animals in motion, the victorian-era products were first invented in the 1830s. By introducing 3D printed sculptures in place of images, Healy says he’s been able to achieve continuous motion.

“The series merges factual and imagined memories of the city [Vancouver, Canada],” explains Healy. “Experienced in the round, the artworks are both stage and performer. Short graphic cycles repeat to form a moving pattern. Playing continuously, the looped motion can be hypnotic, inviting viewers to meditative observation.”

PUNCH Torino and ROBOZE to advance 3D printing

In application news, PUNCH Torino and ROBOZE have agreed to partner to accelerate the industrialization of 3D printing in the automotive and marine sectors. Drawing on the automation provided by ROBOZE’s 3D printers and PUNCH Torino’s expertise in automotive technology, the firms anticipate realizing economic, territorial and environmental benefits, both for themselves and future clients.

“We chose Roboze as our partner because we strongly believe in its patented ultra-precise 3D printing technology for super polymers and composites,” says Gianmarco Boretto, Director Hardware Engineering of PUNCH Torino. “This technology allows us to create increasingly complex, resistant and functionally-integrated systems through the application of specific product development techniques.”

Wematter and Braskem expand reseller networks

Finishing this week with Wematter, the Swedish 3D printer manufacturer has entered into a reseller agreement with German distributor OKM3D. As part of the deal, the latter will work to establish a sales and service network for the Gravity 3D printer in Germany, where Wematter anticipates there being a strong appetite for the system in the automotive and medical markets.

“We are really delighted to work with Wematter and to be able to offer their SLS solution to our German customers,” said Julien Gonzalez, European Distribution Manager of OKM3D. “It’s a great technology and Wematter offers an innovative approach to the ecosystem. There is a wide range of technical materials and the hardware part is very easy to install for such an industrial solution.”

Brazilian petrochemical firm Braskem has struck a similar deal with US resin distributor M. Holland. As a Braskem distributor, M.Holland will now be able to provide access to both polyethylene (PE) and glass fiber reinforced polypropylene (PP) filaments. In doing so, the firm will begin supplying materials made to deliver high printability, as well as reduced warpage and improved interlayer adhesion.

“When 3D printing with PE materials, many of our clients have reported an array of technical difficulties including warping, inconsistent finishes and deficient technical properties. Braskem’s PE material provides an incredible level of thermal stability that makes the material consistent and significantly easier to print,” said Carlos Aponte, Market Manager of 3D Printing at M. Holland. “This PE formulation is groundbreaking, and it’s now readily available for our clients.”

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo above one of Healy’s 3D printed zoetropes and an overhead lamp. Photo via R. James Healy.