In this edition of Sliced, the 3D Printing Industry news digest, we cover the latest business developments, partnerships, and acquisitions in the additive manufacturing sector.

Today’s edition features an update on the US-China space race, military 3D printing deployments, construction legal changes, medical R&D advances and a deal that could see luxury watches 3D printed from recycled metals.

Read on for the most recent updates from Roboze, Xact Metal, nScrypt, Essentium, IperionX, igus, MatterHackers, Uniformity Labs, Evonik, Sigma Additive Solutions, Braskem, Prodways, Mighty Buildings, Headmade Materials, Meltio, Replique, Addifab, Quickparts, Nexa3D, Kimya, AddUp, Oqton, Velo3D, CRP Technology and more.

Ultimaker-MakerBot and Markforged-Digital Metal deals sealed

Kicking off this week’s update with the latest on 3D printing’s biggest business deals, 3D printer manufacturers Ultimaker and MakerBot have completed their merger. Under its new ‘UltiMaker’ brand, the combined company plans to invest in accelerating growth and driving product innovation via R&D, and strengthening its presence across the Americas, EMEA, and Asia-Pacific through market expansions.

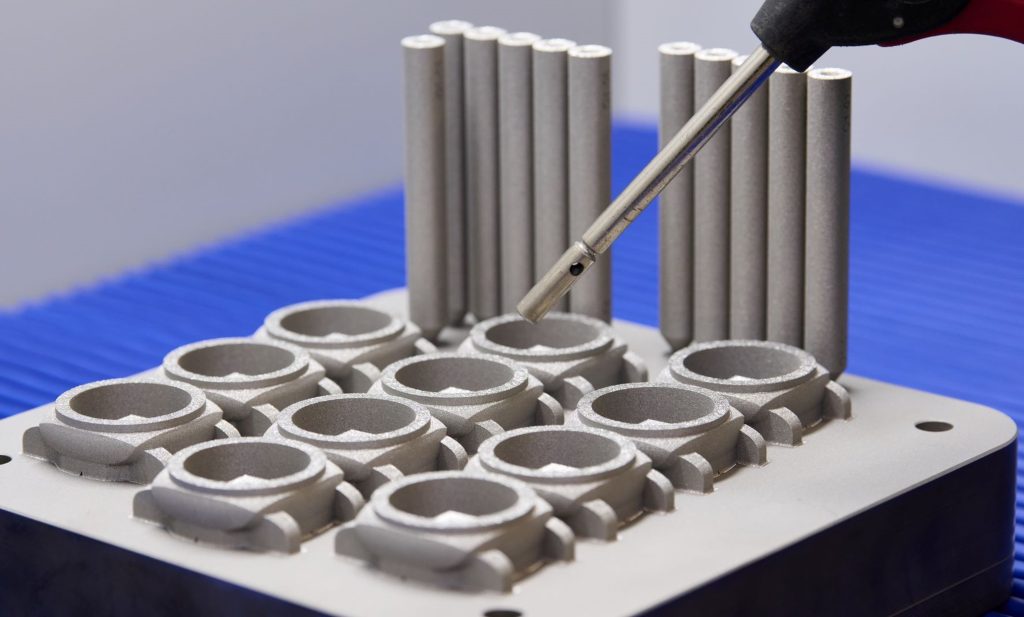

Metal and carbon fiber 3D printer manufacturer Markforged has also completed the acquisition of binder jetting specialist Digital Metal. Through the deal, Markforged has paid Höganäs AB approximately $32 million in cash, 4.1 million shares of common stock and $1.5 million in cash to settle certain intercompany balances.

“Together, we will continue advancing our vision for distributed manufacturing by bringing the high volume production of precise metal parts directly to the point of need,” said Shai Terem, CEO of Markforged. “By integrating Markforged’s software capabilities and global go-to-market engine with Digital Metal’s precise and reliable binder jetting solution, we expect to unlock significant opportunities to further accelerate Digital Metal adoption into our existing and future customers.”

“We are excited to successfully complete the acquisition of Digital Metal, and officially welcome its team to Markforged.”

Elsewhere, German production service provider Blueprint Advanced Manufacturing, has officially opened its doors. The new firm intends to use its state-of-the-art technologies and expertise in surface finishing, custom parts and quality standards to deliver manufacturing services that truly cater for customer-specific requirements.

“We are the interface between the ideas of our technology-driven customers and the solutions for economically viable manufacturing,” says Jens Harmeling Co-Founder of Blueprint Advanced Manufacturing. “We support and enable our partners’ sustainability goals through better use of raw materials, low carbon footprint, and new product morphologies,” adds fellow Co-founder Jordan Kopping.

Roboze, Xact Metal, nScrypt and more add new distributors

On the distribution front, Laser Powder Bed Fusion (LPBF) 3D printer manufacturer Xact Metal has become one of many in the sector to broaden its reseller network. Through a newly-signed deal with Prototech, the firm aims to bring its machines to the South Korean market, and help “reduce the financial barriers” to metal 3D printing there.

Florida-based microdispensing specialist nScrypt has also been busy, signing agreements to engage non-exclusive sales representatives in Australia, Dubai, India and Italy. According to the company’s CEO, Ken Church, these deals with Embedded Logic Solutions, SAT Trading LLC, Ambition Technologies and the NT3D-Group, could now “provide cross-pollination opportunities” for it moving forwards.

Industrial 3D printer manufacturer Roboze has agreed a distribution deal with Boston-based reseller Ugogo3D. Frank Marangell, CEO of the latter, which specializes in marketing 3D printing products to US manufacturers seeking to innovate and in-source, has described Roboze’s as “standout FFF technologies,” making them “ideal for its portfolio.”

Over in Germany, Neotech AMT has signed an agreement with Nextex Ventures (NTV) to market its range of 5-axis systems for 3D printed electronics in North America. NTV Sales, Marketing and Operations Coach, Dean Turnbaugh said: “NTV is excited to partner with Neotech AMT to market 5-axis printing and post processing systems to flexible hybrid electronics and other customers in the US and Canada.”

“This is a high performance and very flexible system that is complementary to the other printing, curing, substrate and ink technologies in the NTV portfolio of partners,” he added.

Essentium, MatterHackers earn military contracts

In the defense sector, High Speed Extrusion (HSE) 3D printer manufacturer Essentium has announced its participation in the US Navy’s Repair Technology Exercise (REPTX). During the two-week initiative at Port Hueneme, California, the firm demonstrated the potential of its technologies as a way of expanding the Navy’s expeditionary maintenance capabilities.

Alongside their fellow REPTX participants, the Essentium team were tasked with tackling a series of real-world based scenarios that involved solving maintenance problems aboard the US Navy’s Self Defense Test Ship. For its part in these, the company deployed a 280i HSE 3D Printer augmented with field deployable features, and it sees the exercise as a step towards “future 3D printing endeavors.”

3D printer provider MatterHackers has also entered into a Cooperative Research and Development Agreement (CRADA) with the Naval Information Warfare Center (NIWC). The deal will see MatterHackers help develop use cases for the Navy and Marine Corps to identify, test, and collect data on effective, low-cost, expeditionary 3D printing technologies.

In practice, this will see the firm providing expertise through both on-site and virtual training, technical support, and equipment, including a wide variety of 3D printers and engineering-grade materials, which are set for deployment in the field.

“The results of the CRADA will potentially aid in accelerating operationalization of commercial off-the-shelf 3D printing for government and military use, a task that has been well underway by the Marine Corps’ Advanced Manufacturing Operations Cell (AMOC),” says Major Matthew Audette, Advanced Manufacturing Systems Team Lead in the US Marine Corps. “AMOC’s goal is to further employ additive manufacturing throughout the Marine Corps, including certifying, storing and sharing files for approved 3D printed parts.”

New raft of material launches and R&D projects unveiled

Moving on to material news now, US 3D printer manufacturer 3D Systems has launched two new production-grade materials: Figure 4 Tough Clear and DuraForm PAx Black. Engineered for long-lasting mechanical performance and stability in any environment, the polymers are said to be ideal for consumer goods, transportation & motorsports, aerospace & defense, and service bureau applications.

Multinational polymer manufacturer igus has introduced a new sintering powder. Compliant with FDA and EU 10/2011 regulations, and formulated to feature a distinctive blue color, i6-BLUE is a highly-abrasion-resistant, self-lubricating material designed to be used in the 3D printing of food-safe worm gears, toothed gears and snap-on connections.

3D printing material developer Uniformity Labs has also released a 17-4PH stainless steel powder for the Desktop Metal Shop Pro Binder Jetting (BJT) platform. Developed by an in-house team of scientists, the material is said to deliver uniform sintering shrinkage across the bed, thus allowing users to binder jet parts up to tens of centimeters in length.

Researchers at the Finland University of Applied Sciences and University of Southern Denmark, meanwhile, have published research into the potential of thermally-conductive 3D printing filaments. In their study, the engineers found they were able to optimize the topology of such materials, so that they can be used to produce passive heat sinks which utilize natural convection to improve performance.

More on the team’s research can be found in their paper titled: “Material extrusion additive manufacturing and experimental testing of topology-optimised passive heat sinks using a thermally-conductive plastic filament.”

In material partnerships, 3D printer OEM Stratasys has unveiled Evonik as its third polymer development partner for the Origin One system. Evonik’s first material for the machine is P3 Deflect 120, a Stratasys-validated feedstock with a heat deflection temperature of up to 120°C, lending it potential manufacturing mold-making applications.

In more Essentium news, the HSE 3D printer manufacturer has begun working with Brazilian petrochemical firm Braskem to offer an ‘integrated AM machine and materials solution.’ In doing so, the firms anticipate being able to further unlock the potential of Braskem ‘FL605R-CF,’ a material sourced from recycled carbon fiber and bottle caps.

Over in France, Digital Light Processing (DLP) 3D printer manufacturer Prodways has struck a material partnership with Henkel. The deal allows users of the firm’s industrial systems to utilize Loctite’s high-performance 3D printing resins.

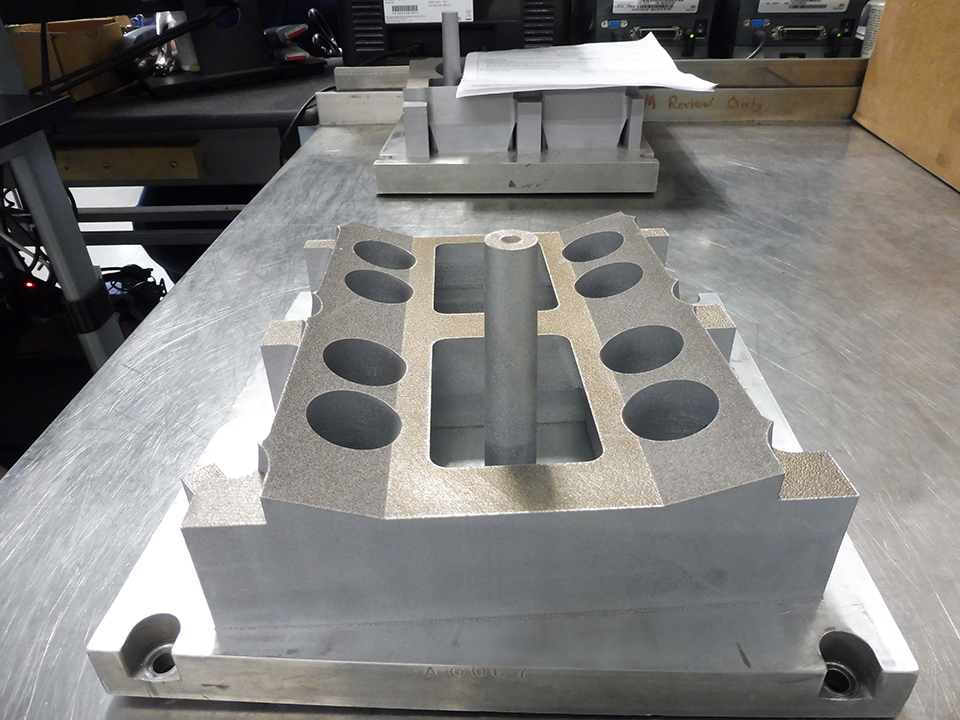

ColdMetalFusion 3D printing developer Headmade Materials has also joined the ‘ColdMetalFusion Alliance,’ a group of industry leaders from the worlds of 3D printing, sintering and industrial manufacturing. Through this alliance, which is due to add further members later in 2022, participants aim to provide services, equipment and know-how to metal manufacturing customers.

“Thanks to ColdMetalFusion we were able to find applications where we can help customers change the rules of the game in their market,” said Christian Fischer, Co-CEO of Headmade Materials. “To enable this at large scale, we are looking forward to forge robust and reliable standards together with the Alliance.”

Mighty Buildings and Von Perry advance construction 3D printing

In construction 3D printing, Dallas-based start-up Von Perry is seeking to crowdfund the building of a $2 million home from geopolymer concrete. Set to be constructed using Total Kustom technology, which allows for the layer-by-layer ‘contour crafting’ of custom housing, the firm anticipates the build will take only four months to complete.

“It will be a streamlined process because they won’t have any kind of confusion,” Von Perry Co-founder Sebin Joseph told Dallas Innovates. “[Workers] will get all of the instructions, showing the design where exactly the fixture should be. So they go do that, and they’re done. That way the process will work smoothly. The customer just comes in, makes the order, and they will get that house built without any hassles.”

Mighty Buildings, on the other hand, has issued a statement saying that it “applauds” the state of California for its passage of bill AB 2446. Formally signed off on September 16, the new law requires the California Air Resources Board to develop a framework for measuring and reducing carbon intensity in the construction of buildings.

With Mighty Buildings having worked closely with California Governor Gavin Newsom to bring the legislation forward, and committing to deliver its own carbon-neutral homes by 2028, its CEO Slava Solonitsyn has hailed its passage as key to “fostering innovation, while at the same time addressing some of the most pressing issues we face today.”

Quickparts, Nexa3D, BOFA, Addifab seal AM partnerships

Danish manufacturing service provider Addifab has agreed to partner with fume and particle extraction specialist BOFA International. Through their collaboration, the former will now use the latter’s technology to support its Freeform Injection Molding (FIM) process, which enables the creation of complex injection molded parts through 3D printed tooling.

Elsewhere, Quickparts, the production service bureau sold by 3D Systems for $82 million in September 2021, has announced two new partnerships. In the first, the company has worked with Gogo Business Aviation to 3D print prototype antennas for an industry trade show. Gogo approached five different providers, but only Quickparts could print the single-piece parts with the speed and finish required.

Since then, the firm has become a Foundational Partner with 3D printer manufacturer Nexa3D. Through the collaboration, Quickparts says it “hopes to bring customers faster production times with the help of Nexa3D’s QLS 820 [3D printer].”

“We are thrilled to be the first on-demand manufacturing service provider to experience the benefits of higher throughput, thermoplastic, additive manufacturing,” said Ziad Abou, CEO of Quickparts. “We pride ourselves on offering quick-turn manufacturing services to our customers and look forward to introducing an even faster and more economical production of higher volume thermoplastic components with Nexa3D’s QLS 820.”

3D printer installations and ancillary launches announced

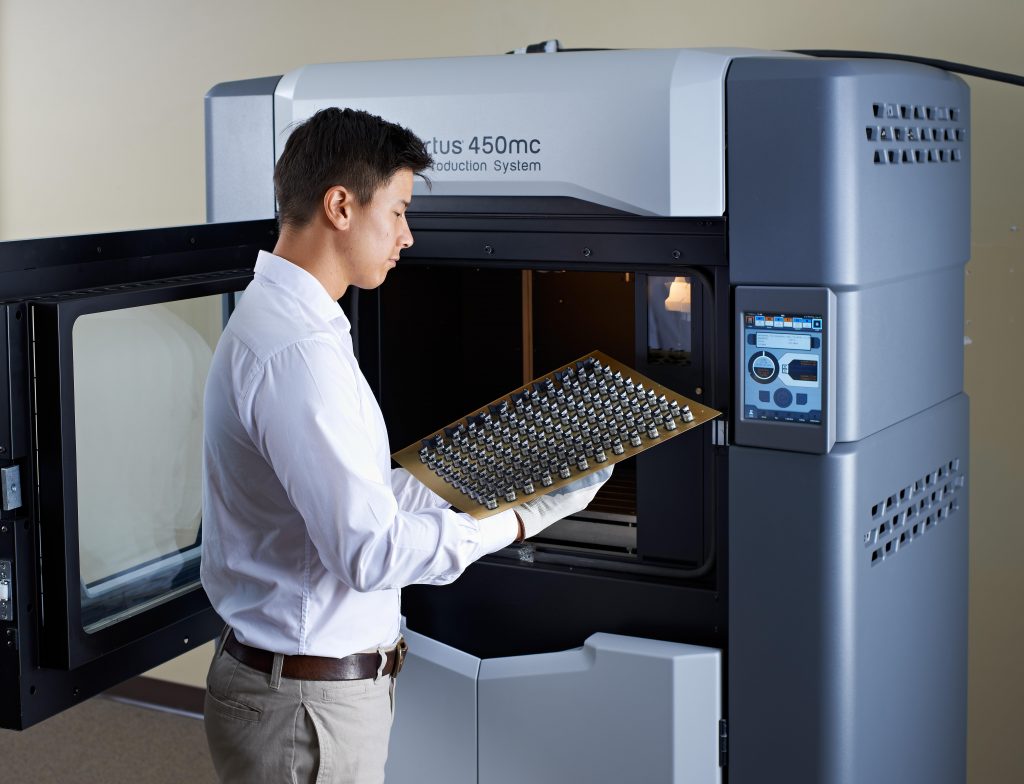

In 3D printer acquisition news, French manufacturing material developer Kimya has invested in two Stratasys Fortus 450mc 3D printers. The deal, which follows the announcement that Kimya is to begin providing two industrial materials to Stratasys users, will allow the former to widen its service offering and create parts for more demanding use cases.

Machine tool maintenance service provider CELADA has announced the adoption of Roboze 3D printing products at its facilities. Guido Celada, President of CELADA says Roboze’s technologies effectively “complete its offering,” by “increasing the application fields of its customers, with industrial, precise, repeatable and high-performance output.”

Texan contract manufacturer Kevton Industries subsidiary Kevton Technologies has bought no fewer than seven Velo3D Sapphire 3D printers. The service production provider’s order, one of Velo3D’s largest ever, will start being fulfilled in Q1 2023.

Over in France, metal 3D printing start-up Addimadour has acquired a Meltio Directed Energy Deposition (DED) head. As well as becoming the first in the country to install the printhead on a 6-axis robotic arm, the acquisition sees the firm build out its platform’s list of equipment, and enables it to create larger parts with greater working precision.

In ancillary launch news, Lynxter has introduced a new direct drive filament toolhead. By locating its extruder motor above its heater block, the firm says its technology decreases friction, reduces material clutter and increases throughput. The FIL21 toolhead also packs compatibility with flexible filaments like TPU, TPE and TPC, in addition to metals and ceramics such as alumina and zirconia.

Lastly in hardware, BASF-incubated 3D printing venture Replique has unveiled plans to launch a new quality tracking module at the Formnext 2022 trade show. Known as ‘RSure,’ the platform is designed to enable OEMs to track each 3D printed part to ensure they meet set quality specifications, and undergo digital inspection.

Stratasys 3D printing transforms Ident’M dental lab

French dental laboratory Ident’M has begun 3D printing models using a Stratasys J5 DentaJet. While the firm had previously switched from creating plaster models to additive manufacturing them instead, it says up to 50% were deemed to be poor quality. Since adopting the J5 DentaJet, however, it has noticed an improvement in the precision, productivity and reliability of its workflow.

“We’re running the J5 20 hours a day, right through the night, which is currently seeing us create around 1,000 different models a month,” says Ident’M Co-director, Frédéric Imbert. “This is a massive benefit, as it means we can send files to be printed and arrive the next day with a full tray of models.”

“We have an obligation to deliver superior precision to our clients, and this 3D printer’s precision is simply unachievable with any other technology today.”

AddUp, Oqton and Sigma issue software updates

French metal 3D printer manufacturer AddUp has announced a partnership with Swedish 3D visualization and data fusion software company Interspectral. Between them, the firms aim to help reduce manufacturers’ quality inspection costs and improve 3D printing efficiency, by developing an advanced melt pool monitoring platform, with real-time power, emissivity drift and laser spot-tracking capabilities.

3D printing software developer Oqton has also expanded the offerings it provides through the Altair Partner Alliance, with the addition of 3DXpert and 3DXpert DfAM (Design for Additive Manufacturing). Adding the end-to-end build preparation and simulation programs, is set to provide users of Altair’s platform with a revised application toolset that streamlines the design and manufacture of complex parts.

At Sigma Additive Solutions, the quality assurance software developer has announced the formation of an in-situ ‘AcGovDustrial’ network. The initiative is designed to offer R&D labs and educational institutions easy and inexpensive access to its platform, while building a network of stakeholders to provide funding, spur the commercialization of new technologies, and advance metal 3D printing.

Stratasys has launched an FDM certification program for its users. Designed to be the first in a new online series, the initiative is designed to ensure customers receive a “comprehensive education” that “supports their adoption of 3D printing.” Those that complete the online courses will receive official Stratasys Academy certificates, which both certify their skills and confirm their level of FDM mastery.

Clinical 3D printing firms in R&D progression, fresh funding drive

In the medical sector, a researcher based at Sydney Adventist Hospital has begun using 3D printing to treat young patients with ear deformities. As part of this ‘NEW EARS’ project, Payal Mukherjee is combining 3D printing, cell biology and material engineering to create silicone prosthetics which are uniquely crafted for individual patients, as well as more experimental transplants from cartilage.

Scientists at the University of Minnesota Twin Cities have 3D printed a light-sensing medical device that, when placed directly on the skin, is able to directly correlate light exposure with disease flare-ups. In future, it’s thought the gadget could offer the sufferers of lupus and other light-sensitive diseases a more tailorable symptom-tracking tool.

In 3D bioprinting, meanwhile, South Korean food start-up TissenBioFarm has raised around $1.6 million via a pre-series A funding round. Using the additional funding, contributed by lead investor Envisioning Partners as well as FuturePlay, Stonebridge Ventures and Mirae Holdings, the firm plans to expand its research facility, reduce its production costs, and prepare to bring its first products to market.

“In the global cultured meat field, it is very challenging to create meat as thick as a steak through cell culture methodology,” said Wonil Han, CEO of TissenBioFarm. “Furthermore, replicating the meat texture and marbling in cultured meat, and mass-producing them requires cutting-edge technologies. With our technologies, we will provide high-quality cultured meat that is competitive in taste, nutrition, sensory, and price in the near future.”

Automotive & aerospace advances in engine, drone and rocket 3D printing

3D printing material developer Uniformity Labs has partnered with race car engine developer Polimotor and metal additive manufacturing firm Incodema3D, to develop a 3D printed Cam Tray. The aluminum engine component was produced as part of a case study, set up to evaluate the benefits of producing it from the former’s powders.

As it turned out, 3D printing the part from Uniformity Labs’ ultra-low porosity AlSi10Mg powder with custom settings on an EOS M290 system, allowed for a slight increase in part density over a component produced using standard EOS settings and an industry-leading material, while also achieving a 181% throughput rise.

3D printing materials and services provider CRP Technology has worked with unmanned helicopter manufacturer FLYING-CAM to 3D print tail rotor gearbox housings for its Discovery UAV. Producing the parts from CRP’s Windform XT 2.0 carbon fiber-filled composite, enabled the firm to improve their tensile strength by 8%, tensile modulus by 22% and elongation at break by 46%.

Over in China, the China Aerospace Science and Technology Corporation has successfully tested the Long March 9, a rocket it claims to be twice as powerful as its US counterpart. Built with the aid of 3D printing, the heavy launch vehicle is designed to facilitate lunar exploration, robotic space exploration and space infrastructure missions.

IperionX to address the premium jewelry market

Finishing off this week with IperionX, the sustainable, low-cost titanium developer has signed a commercial agreement with luxury watchmaker Panerai. Through the deal, the companies have worked together to identify watch designs that can be produced using IperionX’s recycled metal powders, with the first products produced together, limited edition watch cases, set to come to market in 2023.

“Panerai and Richemont have been leaders in the application of titanium metal alloys in luxury watches, and they are again leading the market to build a low carbon, circular supply chain,” said Taso Arima, CEO of IperionX. “Our partnership represents a major milestone in the luxury goods sector. For IperionX, this demonstrates the potential in other consumer facing sectors which are demanding fully recycled and sustainable, low carbon materials.”

“One of the most exciting sectors are the high growth markets in smart watch, wearable device and smartphone markets.”

Nominations for the 2022 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Let us know by casting your vote now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sliced logo on a batch of 3D printed watch blanks being cleaned. Photo via IperionX.