This is an article in our new series looking at how 3D printing is used around the world and reporting on ways to get involved with 3D printing.

3D Printing at FabLab CEPT University, Ahmedabad, India by Tanveer Khorajiya

FabLab CEPT aims to enable everyone to build their ideas.

The space provides access to skilled mentors and peers, tools and learning experiences that allow one to innovate. The FabLab concept is the educational outreach component of MIT’s Center for Bits & Atoms (CBA), an extension of its research into digital fabrication.

FabLabs now connect a global community of learners, makers and innovators. This knowledge sharing network spans 30 countries and 24 time zones and standardises the tools and processes to build a global laboratory for research & invention. Our FabLab premises is part of CEPT University, Ahmedabad in India.

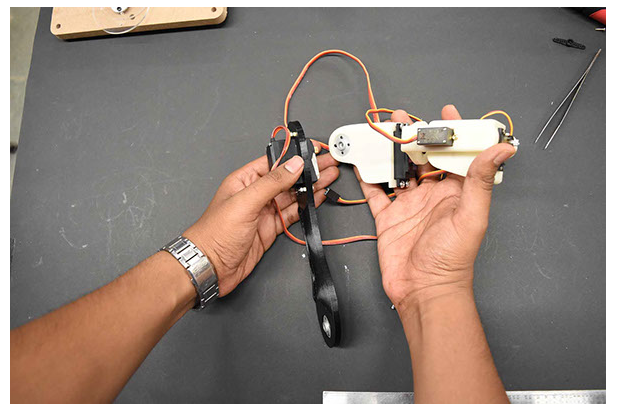

The people who come to our FabLab are from a wide range of backgrounds and academic disciplines. They are united here as Makers. They all have their own creative ideas and our facility helps them to nurture those ideas and build better products.

How we work at FabLab CEPT

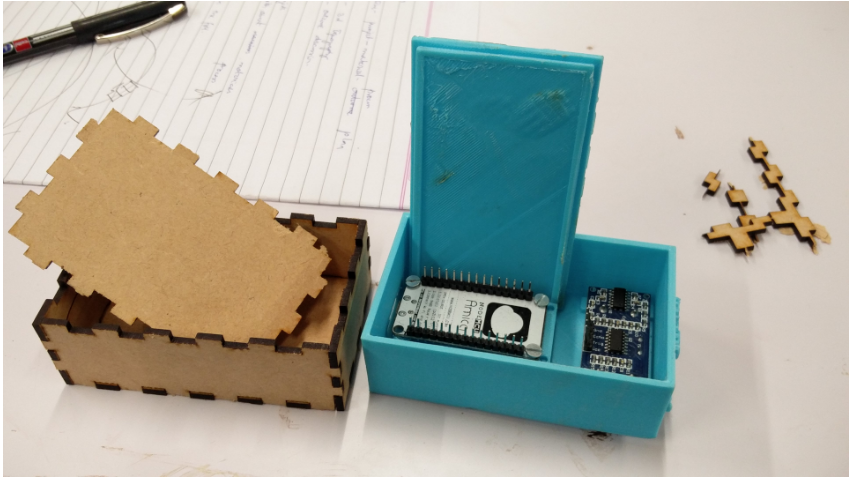

Visualization is the first and most important thing. For this we use various computational design and digital fabrication tools to give shape to the imagination.

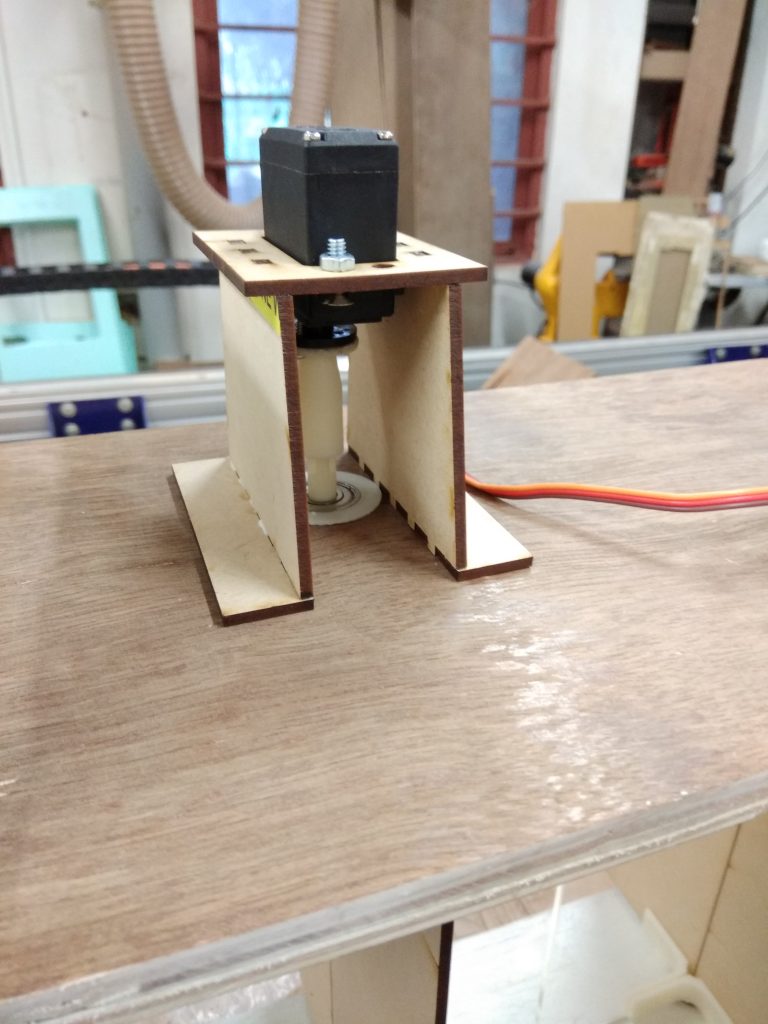

People here are encouraged to experiment and learn, so multiple iteration in development is important. In this process 3D printing helps the community a lot.

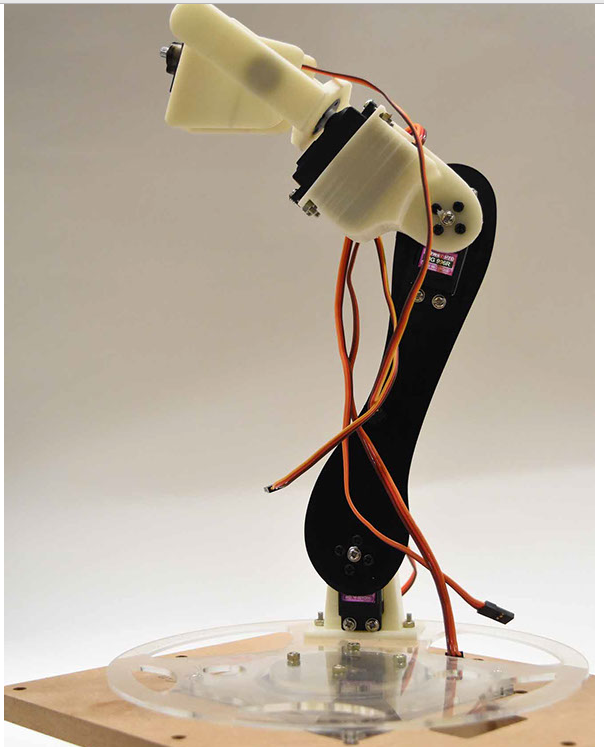

3D printing offers very low design to prototype time, and also permits a high degree of geometrical complexity – this is something appreciated the most by people here.

At FabLab CEPT Makers don’t need to think about machine and its capabilities while designing and sketching. They work on their idea and how it will meet the final objective.

Working with 3D printing in practice

From my experience with 3D printing in past practices and working on various projects ranging from automobile assembly to medical devices, Additive manufacturing is influenced by three important areas. The right 3D printing technique, material, and Gcode settings.

First, 3D printing is more about the selection of the appropriate 3D printing technique. It is important to consider that sometimes you don’t need to go for 3D printing at all. While at other times 3D printing may be critical to choose perfect technique of manufacturing with consideration of end product utility, geometrical requirement and sustainability.

This I believe is something that will change the usability and efficacy of 3D printing at a very high level in product development. I have observed that quality can be an issue with 3D printing, and this leads to dissatisfaction. The cause is frequently not choosing the right technique, material or design slicing settings.

In my workshops questions and queries such as how to optimize these things for a particular product frequently come up.

The second area is about the quality of the 3D print.

Whether the technique chosen is FDM, SLA/DLP, or SLS/DMLS, a lot depends upon design. One can make same simple design in sketchup, Rhino or in CATIA but the mesh these platforms generates while converting it into STL varies widely. This factor makes a huge difference in the quality of the STL file.

This can be controlled in somewhat higher end software like Rhino or Autodesk product development suites such as Fusion 360. So, I always recommend to go with better design and surface generation rather than just creating 3D geometrical shapes.

But to achieve intended result or product and enhanced quality of a 3D print, attention must be paid to the slicing parameters. Greater control can be achieved using specialised slicing software such as Simplify3D, Meshmixer or Netfabb.

These 3rd party software tools can enhance design in such a way that it sends each specific instructions (in form of G code) to the machine. The can improve quality and end results. I recommend generating Gcode via these specialised slicing engines. These tools also facilitate customization options – ranging from variable infill density to manual support structure generation.

At Ahmedabad and in the wider state of Gujarat, the use of 3D printing is increasing. This is a trend seen in business and also within educational research and the Maker communities. We are currently working with a government organization Indo German Tool Room (IGTR) for metal printing. We are under process to sign an official memorandum of usage with this institutions. This will allow us to share knowledge and resources.

We also organize various events throughout the year, these include Summer workshops, Fab Fridays and our yearly Makerfest. At these events we educate different age groups of students and startup communities. The events also allow outside makers and enthusiasts to present their creative work after it is reviewed and approved by us.

Our next Makerfest will be in January 2018. We are also organizing similar events at the National level. Fab Fridays take place each month throughout the year.

Digital fabrication is the goal which we working towards at FabLab CEPT. 3D printing and 3D scanning plays a key role in the ability to manufacture things digitally, plus confers significant advantages.

We always encourage people to use these tools and techniques because this helps them to modify, customize and make things creatively. This creative attitude of work comes from our heritage at CEPT University.

This is an article in our series looking at how Makers and members of the 3D printing community around the world are using 3D printing. If you’d like to participate then get in contact.

For all the latest 3D printing news, sign up to our newsletter and follow us on twitter.

Also, if you want to win a 3D printer then check out this competition.