“Breathe in deeply for a count of four, hold your breath and count to seven. Now exhale slowly for a count to eight, and repeat,” instructs David Hartmann, CEO and founder of Sendinaden, as he leads me through a series of breathing exercises.

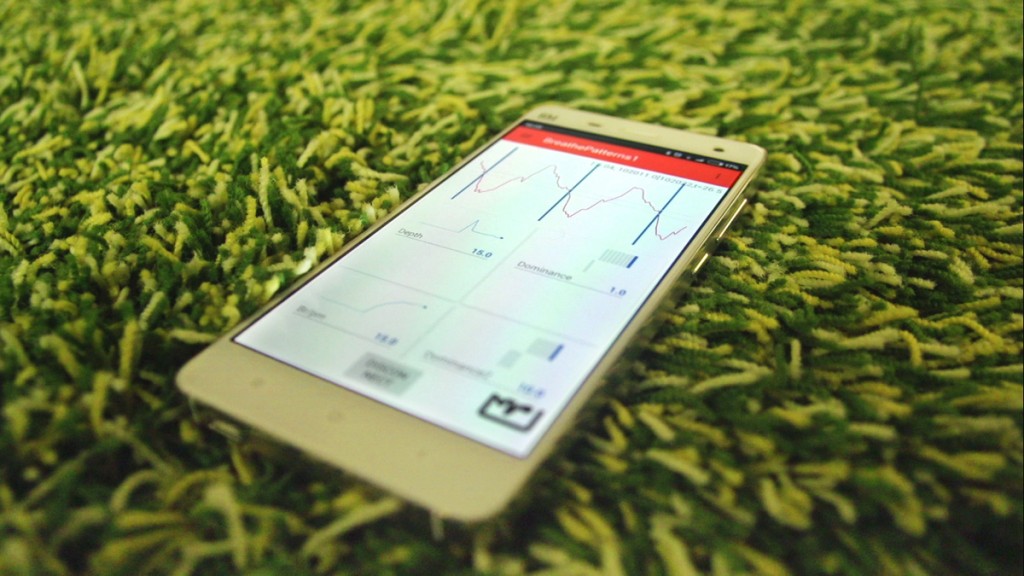

I’m wearing the Pattern Breathe mask, his company’s first product, slated for introduction the first quarter of 2016. Glancing at the screen of his smart phone, I can clearly see the patterns of my breathing—from the speed and depth of each inhalation, to the way I’m using my mouth and nose, as well as other vital statistics. David acknowledges to me that the interface is still a bit rough—a work in progress rather than a finished product. “The algorithms are working really well,” he enthuses, as he removes my mask. “Now, we’re perfecting the user experience.”

I’m in Berlin at the Bayer HealthCare technology accelerator, to get a better understanding of the future of 3D printed consumer electronics, through a hands-on demonstration of an eminent and promising product, the Pattern Breathe mask. Consumer Electronics represents a $1 trillion (US) industry, one that is currently served entirely by injection molding, a traditional manufacturing technique in which hot liquid plastics are injected into a mold and then cooled to form the device housing. Capable of producing thousands of identical objects per hour, injection molding has served the electronics industry well.

However, injection molding is facing growing competition from a young and nimble newcomer: 3D printing, promising technology that delivers a promise of mass customisation, where each product is unique to each user.

“Stress and breathing are highly interconnected,” explains David. “When we breathe too fast or too shallow, we add to the existing stress in our bodies and this can cause serious health problems.” As he speaks, he takes apart the mask, showing the different components, ranging from the 3D printed casing, front panel and strap, to the encapsulated electronics hidden inside. “It’s a two-way relationship. When we breathe well, we reduce the stress on our body from outside influences. We make better decisions at work and we sleep better. Good breathing is the cornerstone of a healthy and happy life.”

Sendinaden is betting that 3D printing will present a serious challenge to injection molding, and cites evidence that the traditional manufacturers understand this inevitability. An example of this is Arburg, the German injection molding technology specialist which has recently announced that it will expand into the 3D printing space.

“Wearable technology represents a completely different paradigm that is best served by 3D printing,” remarks David. “We see a consumer experience where you walk into a retail outlet, get a Pattern Breathe Mask curated and customised for you, go shopping, and come back 45 minutes later to pick up your finished 3D printed mask.”

David is not the only one who sees the potential in 3D printed, user-customised wearables. Sendinaden partner Polymaker, a Chinese-based innovative producer of high-quality filament for extrusion-based desktop 3D printers, prides itself as a leader in recognising unique applications in 3D printing and providing resources and solutions to support the 3D printing community. “Working with Covestro, the leader in the production of engineering plastic Polycarbonate, we’ve brought exciting, new materials to the market that make it possible for functional, engineering-ready objects to be printed via 3D printing,” says Polymaker CEO, Dr. Xiaofan Luo. “Partnerships with companies like Sendinaden ensure that these kind of ready-to-use 3D printed objects will reach the market quickly and change the way people view consumer electronics.”

The Polymaker polycarbonate filaments used to print Sendinaden’s Pattern Breathe Masks, are unique and ideal to the application in use, and are arguably what makes printing these masks with such quality possible. The strap which holds the mask to a user’s face is printed with PolyFlex™, a material that has excellent flexibility, yet is easy to print, holds the mask firmly in place while providing good comfort to wearers. The casing and front panel are both printed in PolyMax™PLA, a unique PLA material that is extremely tough and durable while still safe on skin, perfect for a product worn on the face.

Mass Portal is the printer company that is supporting Sendinaden with printers. The quality of the printer complements the quality of Polymaker’s materials.

Sendinaden’s main goal is to improve the public’s breathing ability. “By encouraging a person to wear the mask during their commute, or an athlete during training, we can help them change their breathing habits to decrease stress or build better sports performance,” says David. “We’re passionate about bringing better breathing and, in turn, a better quality of life to all kinds of people, but particularly to city dwellers in Asia, who face a long commute. They’ve got long periods of down time, and that time is being spent in a high pollution environment where they’re going to wear a mask anyway. It makes sense for them to take advantage of that time to change their breathing habits.”

Sendinaden believes that people worldwide are curious about their breathing patterns and wish to assess their behaviour with a tool that provides them accurate and detailed feedback. Their crowdfunding campaign goes live at the end of November and they’re looking to build a strong community in this space.

Will the arrival of 3D printing as a direct challenger to injection molding change how we see and appreciate consumer electronics? It’s going to be an interesting race to the finish line, and, hopefully, we’ll be breathing more easily as a result.

To answer the question, Sendinaden is launching its Kickstarter campaign on November 23. Interested parties can sign up for the company’s newsletter on their website by visiting sendinaden.com. For more information on Polymaker and their line of filaments, please visit: polymaker.com. Mass Portal’s website can be found at massportal.com.