Recently I was contacted by Andrea Pacciani, an architect specializing in classical Italian design, who developed a passion for “Rose engine lathe” which, as he explained (and as you can see if you Google Image it), are incredible looking machines used in the XVII century to make equally incredible looking containers for the jewels of Kings and Queens.

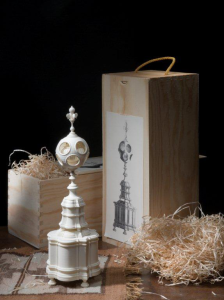

So Pacciani turned to 3D printing to make them. He used the Grolliere de Serviere collection, one of the few that is documented, and re-created the intricate designs form the past in Google Sketchup, which is pretty amazing in and of itself. He then turned to Materialise to have them laser sintered. The result as you can see from the images, is quite breathtaking, and his works have received coverage in art magazines and websites, however, he says, the perceived value is not what one would expect.

“I have featured my designs at online marketplaces such as Etsy and on the Rinkak 3D printing network but, apart form a lot of interest and questions regarding the origin of my designs, I have not obtained significant results from a commercial point of view,” Pacciani explained when I met him for a coffee on a drizzly December morning in Milan. Pacciani believes the reason is likely due to the low perceived value of nylon, compared to the Ivory that the original pieces were made of.

“I would love for someone to begin experimenting, or perhaps collaborate with me to experiment, on the use of materials such as marble powder or other beautiful stones and wooden powders,” Pacciani says. I was not able to suggest many companies that are actively testing new mineral and sand based materials, although the successes obtained by Emerging Objects with salt and other powders in 3D Systems’ Projet x60 class of machines would seem to suggest it can be done.

Materials science and research is at the heart of the 3D printing industry although it is still focusing very much on metals and polymers. Alternative powdered materials used in binder jetting technologies such as the ZCorp/3D Systems Projet x60 and Voxeljet’s – or even in ExOne’s and Digital Metal’s processes – are still extremely limited, with only Emerging Objects carrying out some serious research on possibilities other than gypsum, ceramics and silica sand.

“My research seeks to employ 3D printing technologies to let us repossess the beauty that comes from our history and cultural heritage,” Pacciani said, adding that too often in 3D printing we focus on the process and the ‘nobility’ of the materials is overlooked. “I expect that future binding and melting technologies will be able to use hard stones or organic plastic such as bakelite, ebonite, celluloid or galalite. I think that Italian institutions in particular have the moral duty to carry forth these subjects and I make all my research available to anyone interested in picking up this challenge.” It has been 400 years, isn’t it time to bring these futuristic looking pieces into that future that they belong to?