Scientists at the Catholic University of Korea and Asan Medical Center have 3D printed a novel device that could be used to stabilize Acute Liver Failure (ALF) patients as they wait for a life-saving organ donation.

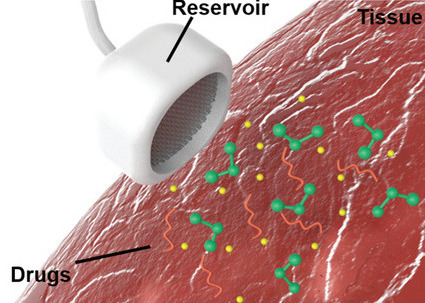

Composed of a 3D printed container and semipermeable membrane, the team’s implant allows for the rapid delivery of the drugs needed to save those in danger of succumbing to ALF. Once implanted, the device also acts as a ‘bioartificial support system,’ functioning as the patient’s liver while reducing any dysfunction caused to their other internal organs, keeping them alive until a transplant becomes available.

ALF: a transplant emergency

In many cases, ALF patients suffer such severe liver damage that their organ’s constituent hepatocyte cells begin to malfunction, in a rapidly deteriorating situation that can prove fatal. With regards to treatment, orthotopic liver transplantation is the only proven cure for final-stage liver disease, and in practice, donor scarcity often limits its use.

Additionally, liver transplants can be costly, and due to organ incompatibility and issues surrounding patient body rejection, the procedure also brings with it a significant risk of mortality. As a result, scientists have increasingly sought to identify new ways of delivering life-saving Active Pharmaceutical Ingredients (or APIs) to damaged liver tissues, via complex implantable drug-delivery devices.

Earlier this year, for instance, a group of researchers developed a novel method of using encapsulated stem cells to treat chronic liver injuries, but according to the Korean team, their approach has low repeatability, and the device itself proved difficult to shape into the geometry necessary for treating damaged liver tissues.

A lifesaving delivery device

To get around the structural limitations seen in previous designs, the researchers used a Cubicon Style 3D printer to produce a set of implantable TPU API-loaded reservoirs. Thanks to 3D printing’s inherent flexibility, the team was able to iteratively develop drug delivery devices in multiple forms, with each featuring a ‘port’ that enables the medication to be continuously delivered to damaged tissues.

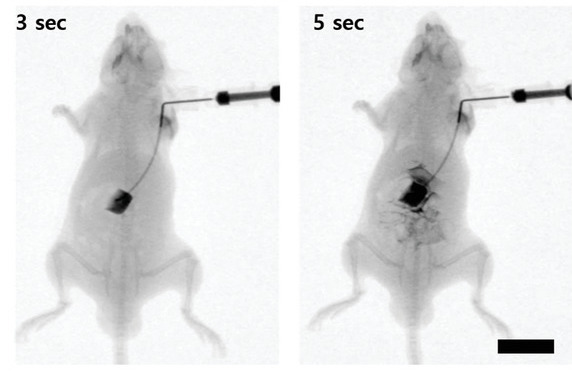

Interestingly, by configuring the pore size of their reservoir, the scientists found they could customize their devices to selectively deliver drugs of various weights, and specifically design their prototypes’ ports for the connection of syringes, thus during initial implantation tests on lab mice, the team was able to refill their devices multiple times and at will.

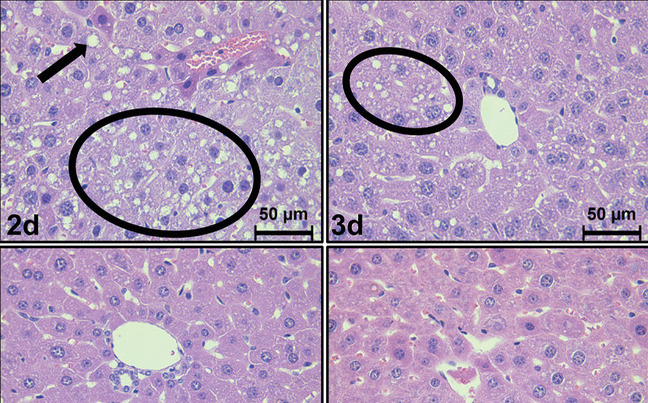

Even more impressively, over a four-week period, none of the scientists’ test subjects showed any sign of changes to either their behavior or body weight. Having established that their device was capable of consistent drug delivery, the researchers later tested its efficacy by ‘treating’ thirty-four 70%-scale resected mouse liver models.

Of these tiny livers, only one died within three days of surgery, while the scientists observed no “abnormal clinical signs,” and some models responded to API infusion by growing back 85% of their mass. Consequently, citing their testing success, the team concluded their device to represent a novel ‘bridge therapy,’ with the potential to not just keep patients’ livers alive, but actually instigate organ regrowth.

However, while the Korean team is confident in their system’s therapeutic capabilities, they have conceded that in practice, its non-biodegradable nature means it would need to be removed via a painful secondary surgery and could even trigger bodily rejection, thus they say future iterations should be built from more human-friendly materials instead.

“[Our] biodegradable implants have long-term potential as a foreign material that remains in the abdominal cavity of mice, [but] this can require additional secondary surgery for implant removal,” concluded the team in their paper. “Thus, for clinical approaches, a biodegradable device or permanent version, should be selected for acute therapy or long-term effects, respectively.”

A bioprinted liver alternative?

While 3D bioprinting full human organs remains a long way from reality, the Korean team’s device shows how the technology can be deployed to heal existing tissues instead. Likewise, in a similar study, T&R Biofab revealed earlier this month that it had managed to 3D bioprint and implant liver ‘lobule’ tissues, with potential regenerative medicine applications.

When recently questioned on the viability of bioprinting as an animal testing substitute, the Brain Research Institute’s Juan Carlos Marvizon was also broadly supportive of this view. According to Marvizon, the technology’s potential lies in regenerative medicine rather than drug testing, where interactions between human tissues are often very difficult to replicate.

Elsewhere, in terms of drug delivery innovation, 3D printing’s research community has really come up trumps over the last year, with scientists at the University of Kent and the University of Strathclyde creating a novel transdermal drug delivery system, while at ETH Zurich, another team has 3D printed microbots capable of ‘carrying’ drugs along blood vessels.

The researchers’ findings are detailed in their paper titled “Design and Usability Evaluations of a 3D-Printed Implantable Drug Delivery Device for Acute Liver Failure in Preclinical Settings.”

The study was co-authored by Shin-Young Kim, Ginam Han, Da-Bin Hwang, Dong-Hoon Won, Yoo-Sub Shin, Changuk Kim, Jeon Min Kang, Jung-Hoon Park, Hyun-Do Jung, Wooram Park, and Jun-Won Yun.

The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, de-briefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the layout of the Korean researchers’ 3D printed drug-delivery device. Image via the Advanced Healthcare Materials journal.