Rheumatoid arthritis is a disabling auto-immune disease. It is a painful condition, can cause severe disability and ultimately impair a person’s ability to carry out everyday tasks. Symptoms include joint swelling and stiffness that often leave the sufferer feeling generally unwell. Now, a new type of 3D printed splint has been designed that will be able to provide far greater support for suffers of this debilitating disease by empowering clinicians with no experience in computer-aided design to provide custom-made wrist splints.

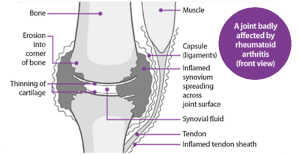

Rheumatoid arthritis causes inflammation in the synovium. The result is comparable to the inflammation of an infected cut or wound — redness, swelling, the production of extra fluid and pain. The redness is caused by an increase in blood flow, which may make the inflamed joint may feel warmer than usual. The inflammation is caused by a build-up of fluid and cells in the synovium. The joint hurts for two reasons: Nerve endings are irritated by the chemicals the inflammation produces, or the capsule is stretched by the joint’s swelling.

Estimates suggest that the prevalence of rheumatoid arthritis varies between 0.3% and 1% [1] and is more common in women and in developed countries. In most countries it is not possible [2] to estimate the prevalence of rheumatic diseases from national health information systems. Exceptions include Finland and Sweden, which have registers of those entitled to reimbursable medication that can be linked to registers of death and malignancy. Another notable exception is the United Kingdom, where primary care physicians record the reason for every consultation. In the UK alone there are some 690,000 [3] adults living with the condition. Within 10 years of onset, at least 50% of patients in developed countries are unable to hold down a full-time job. The disease is economically costly with total UK costs at £3.8 – £4.75 billion per year. Britain also has around 12,000 children under the age of 16 with the juvenile form of the disease.

It is in the UK that a university lecturer has developed a computer software concept that will enable clinicians with no experience of CAD to design and make custom-made 3D printed wrist splints for rheumatoid arthritis sufferers. Dr. Abby Paterson, from the Design School of Loughborough University has designed the software for the customised production of 3D printed splints, which hold the potential to be much more comfortable, also more attractive, and potentially with lower costs than existing solutions.

Dr. Paterson explains: “I wanted to give clinicians the ability to make splints they have not been able to make before. They can improve the aesthetics, the fit, and integrate extra bits of functionality they couldn’t do before as a result of our additive manufacturing facilities here at Loughborough University. Thanks to our Objet Connex machine, we can integrate multiple materials in a single splint such as rubber-like integral hinges or cushioning features but, more importantly, the specialised software prototype we’ve developed will enable clinicians to design these splints for their patients.”

The splints are the outcome of research incepted by Dr. Paterson during her PhD at Loughbourough University between 2009 and 2012 when she was supervised by Dr. Ian Campbell and Dr. Richard Bibb who posited the concept for bespoke wrist splints in the late 1990’s. Dr Bibb, Reader in Medical Applications of Design at the Loughborough University Design School, said: “We are in the development phase. The research has proved that this is desirable and the clinicians want it. We know there’s lots of potential.”

The innovative splints are made by scanning a patient’s arm in the appropriate position for an extrapolation of the precise dimensions that will provide the most comfortable fit for the individual. The digital file can then be 3D printed, producing as many splints as are needed, effectively resulting in fully wearable end use iterations of the splint design. Given the multi-colour, multi-material capacity of the Stratasys Objet Connex 3D printers that are being used by the team, the splints feature multiple materials to maximise comfort and fit. The splints utilise the aptitude of additive manufacturing techniques to produce precise complex geometries to form a lattice design that aids ventilation for the patient’s arm, and can be used with any type of fastening that the patient requires for ease of use.

Doctors Bibb and Paterson are currently now performing a thorough cost analysis of service provision for the custom splints, with estimates that the 3D printed splints should be more cost-efficient than equivalents produced by traditional means of manufacturing. The doctors project that with financial backing they could perfect the software to begin empowering clinicians to customise these splints within just eighteen months.

[1] Chronic rheumatic conditions – World Health Organisation [2] The global burden of rheumatoid arthritis in the year 2000 – Deborah Symmons Colin Mathers, Bruce Pfleger [3] What Is RA? – Ailsa Bosworth, Chief Executive, National RA SocietyImage Credits: Top – Arthritis Research UK; Bottom – Loughborough University