3D designer Bartłomiej Gaczorek has produced a mask that filters out polluted air on a Sinterit Lisa SLS 3D printer.

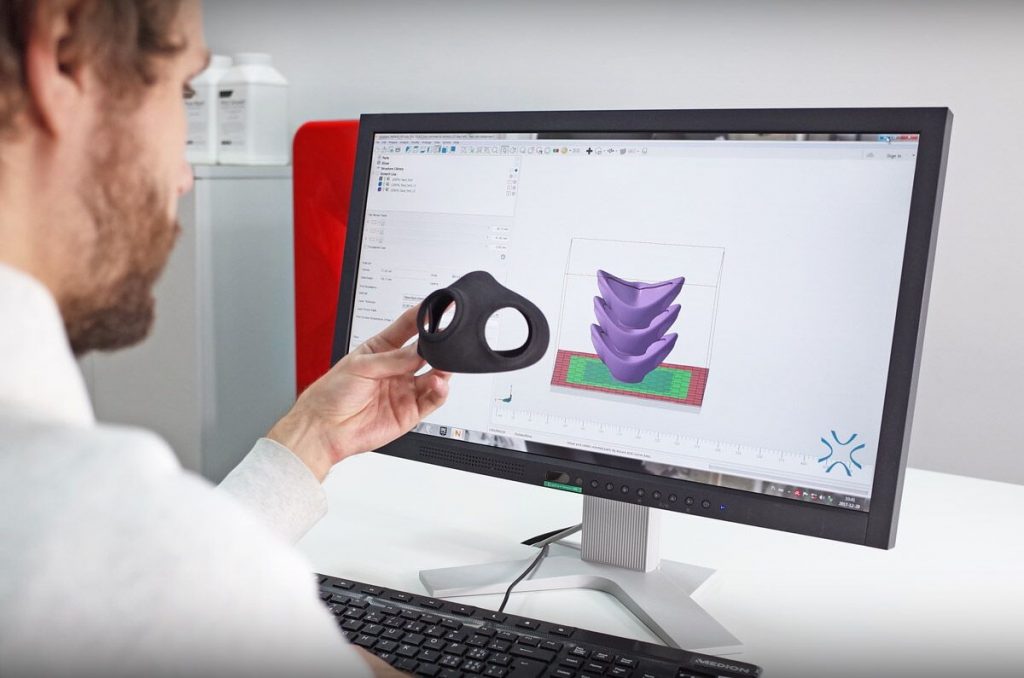

Gaczorek, who has previously 3D printed an exoskeleton for children suffering from SMA (Spinal Muscular Atrophy), designed the “brifo” mask, also aimed at younger users, on Autodesk Netfabb, before SLS 3D printing it with multiple materials.

The bare necessities of a mask

Protective cover for the mouth and nose is sometimes necessary for children, be it from air pollution or the fumes in play-paint. Surgical masks, while effective, can be uncomfortable and unattractive to children.

Custom 3D printed options exist for adults, such as protective face masks and health monitoring smart masks. However, children’s masks require special characteristics, including a lightweight design, protection for filters, and an eye-catching appearance.

Designing the mask

Gaczorek used Autodesk Netfabb to design a mask that fulfilled these criteria. To make it lightweight, the design incorporated internal lattices and air cavities, without compromising its strength.

These were calculated using Netfabb itself, avoiding mistakes that might weaken the mask’s overall structure. The software also detected design problems, repaired meshes, and automatically generated supports.

“A solid piece can be hollowed and filled with crystal-like lattice structures and vents for removing unsintered powder can be added in few simple steps,” said Gaczorek. “This reduces the final weight and material consumption by 50% compared to a solid part.”

Finally, Gaczorek gave the front of the mask an imaginative, child-friendly appearance.

3D printing the protective mask

The Autodesk Netfabb workflow allowed Gaczorek to export the design files directly to the 3D printer without any need to convert formats. The automatic packing feature maximized the use of the print bed.

The Sinterit Lisa manufactured permanent end-use elements that could be treated and painted after 3D printing. Multiple materials were also 3D printed on the same printer, TPU for the flexible and adjustable parts around the mouth, and PA12 Nylon for the more rigid parts on the front and protecting the filters.

The resulting “brifo” mask had a smooth front and complex internal lattices. It met the requirements of durability, functionality and low weight, a combination achievable only through 3D printing.

“SLS is a technology of 3D printing with almost no restrictions in the shaping of parts, perfect for organic and complex geometries and even interlocking elements,” said Gaczorek.

Make your nominations for the 3D Printing Industry Awards 2018 now.

For more information on 3D printing and product design, subscribe to our free 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Featured image shows a child wearing a brifo mask. Photo via Sinterit.