Could the Holy Grail of 3D particle printing be just within reach? Based on the hype in this industry, probably not, but my fingers are crossed and my naive optimism is on red alert as Northeastern University unveils its new nano particle 3D printer.

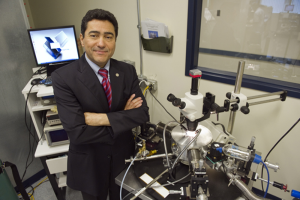

According to the Boston Globe, the university’s patented Nanoscale Offset Printing System (NanoOps) is capable of 3D printing layers as thin as 20 nanometers, 4,000 x thinner than a human hair. Unlike traditional 3D printers, it doesn’t extrude a material or use UV light to harden resin. Rather the researchers at Northeastern’s Center for High-rate Nanomanufacturing (CHN) have developed a technique called directed assembly, in which a mold is created, coated in a thin layer of nanowires, and introduced to electricity, attracting a layer of nanoparticles. Director of CHN, Professor Ahmed Busnaina, compares the process to printing money, telling news @ Northeastern:

What we have developed at our center is a system that’s like newspaper printing or printing money, where you have a big plate, you put ink on it, and bang: One hit, you’re done. Only here, the ink is made of very small and very sensitive nanoparticles attracted to the template using electrophoresis, so we have to pick exact dimensions and materials.

We put a template with a pattern represented by nanowires into a solution that is similar to ink, but very dilute. Then we apply a couple of volts so that nanoparticles in the ink are drawn to the nanowires. Then we take out the template and transfer the assembled nanoparticles to a surface of either a hard or flexible substrate. That would be the first layer of a device, which takes about a minute or two. A sensor may have just a few layers, where advanced electronics may have 10 layers or more.

Depending on the voltage used, the machine can control the number of particles attracted to the nanowires and, as a result, how thick the printed object will be. Busnaina goes on to say that, not only can directed assembly construct small scale sensors, but large objects as well. And, by constructing powerful microchips layer by layer at the micro-scale, instead of whittling down a chunk of silicon, electronics could be made smaller and more affordable:

Directed assembly allows 3-D printing to be faster, cheaper, and multiscale. It can do nano, micro, and macro simultaneously over a large area. No 3-D printer can do that; this is beyond the current 3-D printing technology. This will reduce the cost of expensive electronics such as an iPhone for less than $10 and sensor systems for a fraction of a dollar. These could be sensors for health, the environment, infrastructure, water resources, anything. They will make advanced products affordable to people in all income classes, not just high-income populations or countries.

The NanoOPS device isn’t limited to metals, but can be used on any nanoparticle, including drug particles to bypass injectable medicines in favor of thin swatches that can be absorbed in the skin. Regardless of the application, he believes that the device cuts the cost of manufacturing dramatically:

Our technology is very low cost, about 1 percent of conventional electronics manufacturing, where the equipment and methods are expensive. With our approach, once you make one of our templates (which are not cheap to make), you can use it thousands of times and the method is very simple. Also, the energy cost is very sustainable—you only need two or three volts! You don’t need high temperatures, you don’t need vacuum, so there’s very low energy consumption and infrastructure costs. This turns everything on its head.

Dr. Busnaina’s magic machine was funded partially through the National Science Foundation and the Massachusetts Technology Collaborative, with $24.5 million and $7 million from each respectively. It was also developed in conjunction with industrial printer manufacturer Milara Inc., which will team with Northeastern to sell the NanoOPS to medical device, electronics, and other manufacturers with a price tag between $1 and $1.5 million.

The professor tells The Boston Globe that skin sensors for monitoring the body could be created in the short-term and that the results of the technology could even trickle down to consumers in to years.