Over the past year we have seen dozens of amazing new projects leveraging 3D printing to make people’s lives better, especially the lives of those who suffer from very specific disabilities, which require customized treatments, and supports. Cerebral Palsy, a group of permanent movement disorders that appear in early childhood, is one of these conditions. It affected little Diamo and was the reason why his parents, Samiya and Naveed Parvez, set out to develop and launch the Andiamo Project to produce low-cost custom supports. Now, with the support of 3D Hubs

After a very successful Indiegogo campaign, where the Adiamo Project was able to raise £63,718 for manufacturing custom orthotics, they have now launched a new campaign on Kickstarter with a new animated introductory video to present their project to the the world.

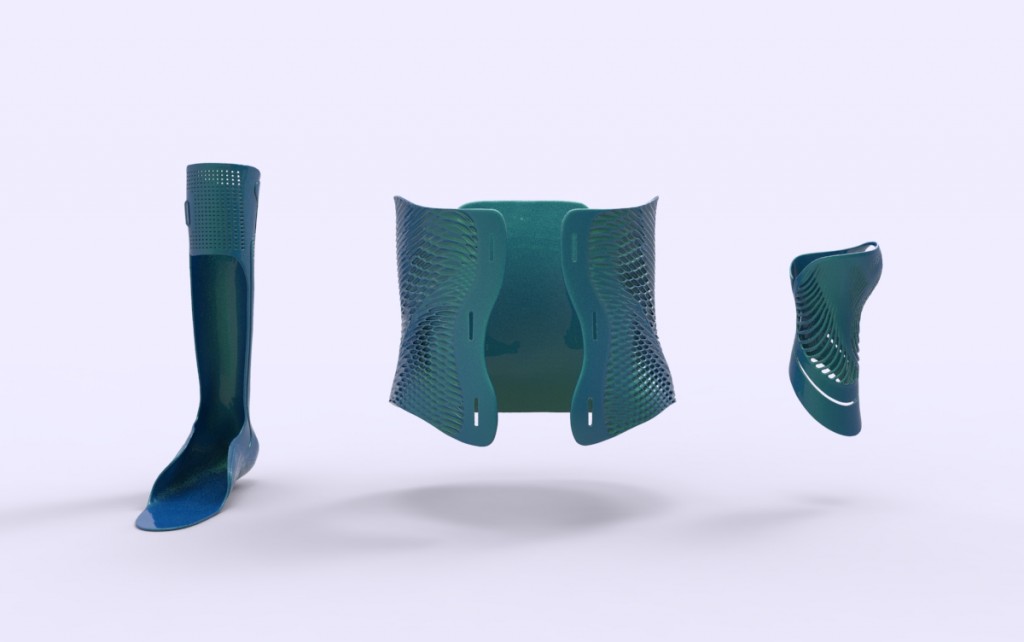

Andiamo, a word which means “let’s go” in Italian, uses 3D scanning and 3D printing technologies to drastically reduce wait times for manufacturing custom body supports from 28 weeks to 48 hours . 3D printing also enables them to make the supports better looking, basing them on the “design pillars” of Magic, Beauty, and Invisibility. Equally as important, the high precision of digital manufacturing technologies makes it possible to develop a perfect fit, which is particularly relevant when the support needs to be worn for up to 18 hours at a time.

This latest crowdfunding campaign does not reward supporters with the actual orthoses themselves, instead offering a limited edition 3D printed sculpture (the Quinn Horse) or crutch-shaped jewel (the Ulman Charm) inspired by Andiamo. The 3D Hubs network got involved making it possible to get the rewards 3D printed by any Hub “near you”.

Past processes for such devices included covering a child in a plate to make a mold, requiring the child to hold still for hours on end until it dried. It would take months to receive the final product, at which time, the child may already have already outgrown it. The need for a custom-made support affects over 100 million families worldwide.

Producing the orthoses from a digital design, also enables the Andiamo team to produce different supports for different needs and situations at only a slightly higher cost. Printing more than one object at a time in the same bed makes it possible to not only democratize the process but also to offer these services to anyone all over the world.