The Wohlers Report 2018 was published last week. As in previous years, I caught up with Principal Author Terry Wohlers to learn more.

The Wohlers Report is always eagerly awaited and regarded by many as the definitive guide to our industry. The vast amount of data provided has launched a thousand power-point presentations, and makes Terry Wohlers one of the most in-demand, and well respected analysts in the 3D printing industry.

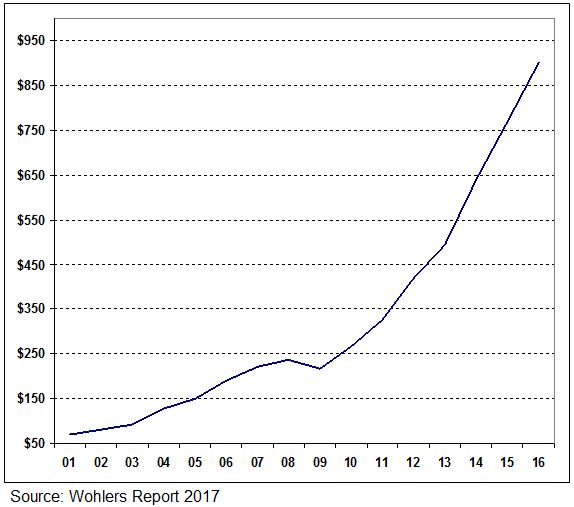

The 2018 report shows that overall the 3D printing industry grew by 21% in the 2017/18 reporting period. This figure is an increase on the 17.4% in worldwide revenues from 2016, and is edging closer to the 25.9% growth reported in 2015.

For 23 years Wohlers Associates has published this important report covering the additive manufacturing landscape and the state of the industrial 3D printing industry.

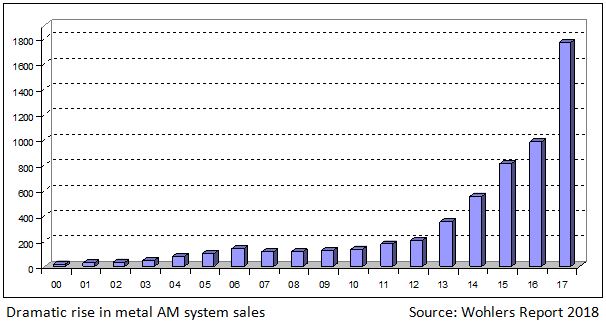

2018’s report contains a number of remarkable figures. These include the fact a phenomenal number of metal 3D printers were sold in 2017. According to the 2018 Wohlers Report, a total of 1,768 metal additive manufacturing systems were purchased in 2017. This is an increase of approximately 80% on 2016, when 983 industrial metal 3D printing systems were sold.

3D printing industry grew by $1.25 billion in 2017

The Wohlers Report also provides useful data on the number of companies selling industrial additive manufacturing systems, a total of 135 in 2017 compared to 97 in 2016.

The term ‘industrial AM system’ is defined in the report as, “machines that sell for more than $5,000.”

To learn more about what drove a $1.25 billion expansion in the 3D printing industry, and to get behind the headline figures, I asked Terry Wohlers, Principal Consultant and President of Wohlers Associates Inc. a few questions.

3D Printing Industry: The 80% increase in metal AM systems on 2016 figures is a remarkable number. Can you tell us anymore about what is driving this number? Is this a one-off or will 2018 see a similar increase?

Terry Wohlers: Desktop Metal sales, reported for the first time, contributed 20.2% of the total. Some users of metal AM systems (i.e., metal powder bed fusion) are beginning to hit a stride that requires more capacity, so they are buying multiple machines. This is much different than in the past when one or two machines were sufficient for testing and qualification of the materials and processes.

It’s impossible to know what the future holds, but every indication suggests that 2018 will be another strong year.

3D Printing Industry: Likewise, the increase in companies producing industrial AM systems is impressive. Are there any specific factors behind this?

Terry Wohlers: Many patents have expired, so this has been a factor. Some countries in Asia, such as China and India, were slow to adopt AM in a serious way, but they are now investing in it.

Many new system manufacturers are especially emerging in China.

3D Printing Industry: You’ve mentioned in the past, including at Formnext 2017, the need to lower material costs. Do you see this as the key barrier to widespread adoption of AM, or are there other specific barriers the industry needs to address?

Terry Wohlers: Material pricing continues to be a major obstacle to growth for production applications. The problem will take care of itself over time, largely through competition. Design for additive manufacturing and costs associated with post-processing are also barriers to growth.

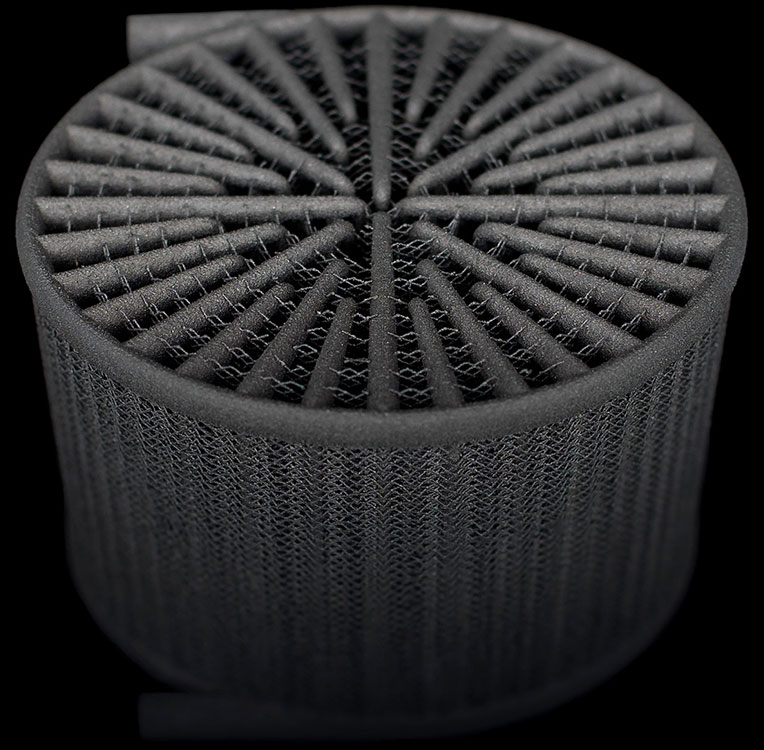

3D Printing Industry: Design for Additive Manufacturing [DfAM]is a frequent theme in your presentations, and has a dedicated section in the report. What are your thoughts about how AM users are engaging with this topic and importantly putting it into practice?

Terry Wohlers: It has been slow, mainly because companies must make a commitment to using AM for production, and doing the analysis is not trivial. This is especially true when considering the cost implications of so many design scenarios.

3D Printing Industry: What surprised you most during the March/March period the new report covers?

Terry Wohlers: We were surprised by the rapid growth in metal AM systems sales. Also, we were surprised by the continued growth in the number of new manufacturers of industrial AM systems.

It’s not an exaggeration to say we’re seeing explosive growth with both.

The Wohlers Report 2018 has seventy-six co-authors and contributors from 32 countries, 344 pages with 36 charts and graphs, 110 tables, and 192 photographs and illustrations spanning 160 additional pages of supplemental data. You can order a copy of the 2018 Wohlers Report online.

You can read further 3D printing insights from the 2017 Wohlers Report in our previous years interview.

Voting is currently underway in the 2018 3D Printing Industry Awards, let us know who is leading the additive manufacturing sector now.

For all the latest 3D printing news and insights – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking for job in this ‘explosive’ industry? The 3D Printing Industry Jobs is live. Post a job or discover your next career move now.