At the end of last year, Davide Sher predicted that 2016 would see metal 3D printing move from a technology capable of producing small batches to a fully-automated method for serial manufacturing. Davide cited a number of machines in development that herald the age of serial metal 3D printing, but he may have left one system out: the Hyproline platform.

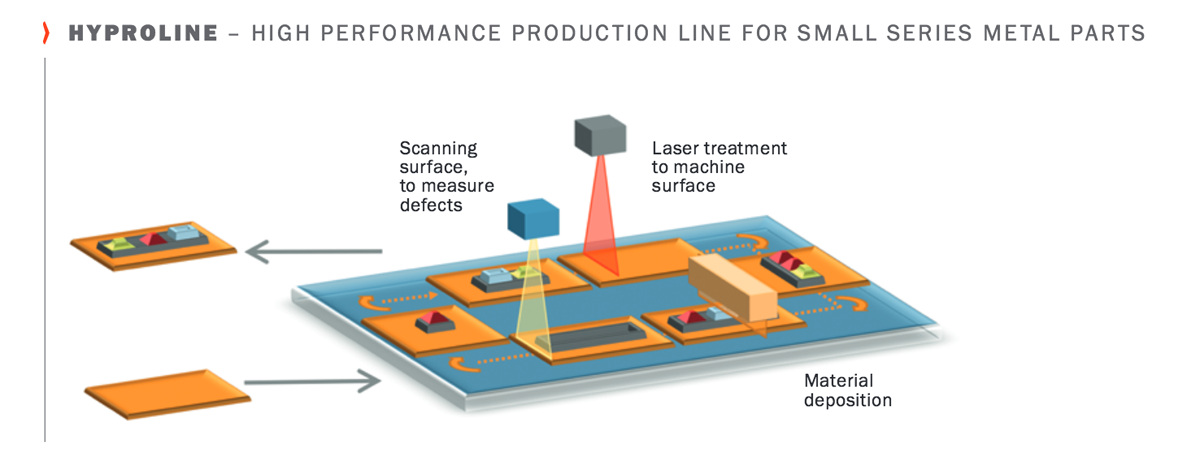

The Hyproline is the result of an EU additive manufacturing initiative began in 2012 to create a high-performance production line for small series metal parts. After several years, the group of industry partners involved, including researcher organization TNO and Swedish metal printer manufacturer Höganäs, have finalized the Hyproline system. The machine uses a similar platform as TNO’s PrintValley, which involves a conveyor belt mechanism to pass multiple build plates beneath a print head. The result is an automated assembly line that can produce a variety of custom parts at high speed.

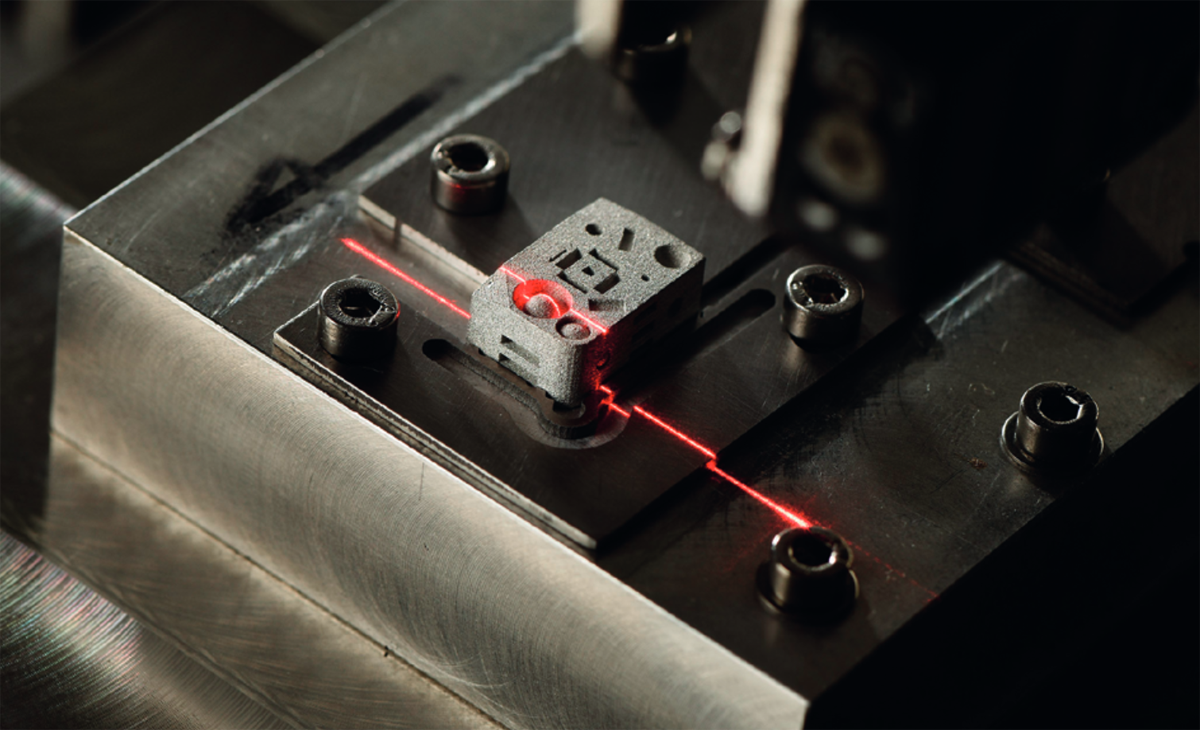

In this case, the Hyproline machine uses 100 build platforms, a 3D scanner, metal deposition, and laser machining to produce 100 separate parts at speeds of 1-2 m/s. Once printed, the parts are machined and polished and removed from the printbed automatically. Parts can be produced with 20 μm resolution from steel, copper, and titanium and, due to the ability to laser machine the metal, the surface roughness can be as fine as 0.5μm. A Micro-Epsilon Scancontrol laser line scanner also allows the machine to perform in-process quality control, which relies on CADfix software from International TechneGroup Limited (ITI) in the UK to inspect and analyze products, matching prints against their CAD files.

Frits Feenstra, senior project manager at TNO, says of the project, “The concept was initially focused on SMEs in the electronics and aerospace industries, but has potential application in other industries that produce low volume, high precision metal parts. We are excited about further developing this manufacturing platform to enable fully-integrated mass production of customized 3D printed products.”

Mark Gammon, ITI, comments about the use of CADfix in the platform, “CADfix is ideally suited for this type of additive manufacturing because of its flexible, closely linked representations of geometry, ranging from continuous CAD geometry to discrete facetted geometry, such as facets, slices or point clouds. Access to multiple forms of geometry enables CADfix to be applied very effectively to all aspects of the AM geometry process chain. This endeavor was truly ground-breaking because of the high-speed of laser polishing of the metal parts, combined with 3D scanning to produce multiple, unique parts in the same run, on the same production line.”

Altogether, the Hyproline system may be one of the most advanced metal 3D printers yet developed, tackling two of the biggest problems in metal 3D printing: quality control and batch production. Both are being pursued by numerous companies at the moment, but this machine seems to combine both in a way that could be unprecedented. Davide very well may have been right.