3D printing using composite materials is the subject of a conference taking place this week at Skolkovo aka the Russian Silicon Valley. The $4 billion Skolkovo Technopark is located 10 miles west of Moscow and is intended to be hub for innovative startups.

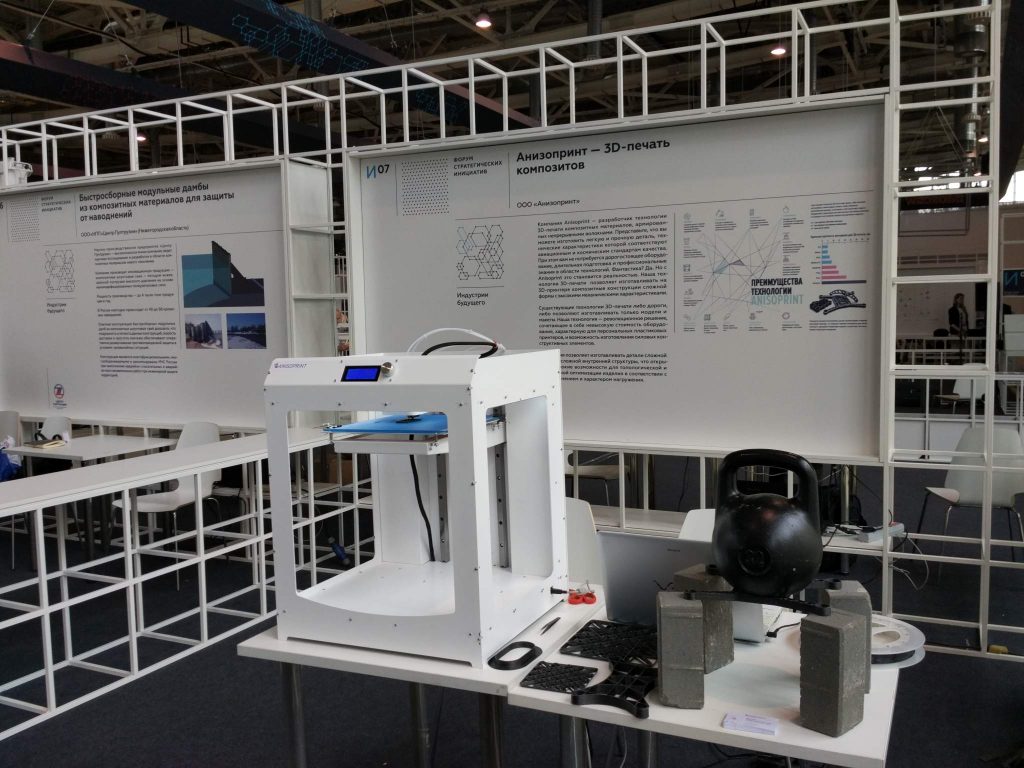

One such enterprise is Anisoprint, a 3D printer manufacturer founded in 2015 who plan to connect, “the world of 3D printing with the world of high performance fiber reinforced plastics.”

Anisoprint CTO, Andrey Azarov says, “Our technology is another step towards the new industrial revolution, which will move us away from the standardized mass production and reveal new horizons of human creativity.”

In 2015, Anisoprint won a startup competition and has since been developing a 3D printer that can work with composite materials to produce structural parts with the strength and other properties required for end use applications in robotics, aviation and other mechanical engineering scenarios.

3D Printing with composite materials

Regular readers of 3D Printing Industry will already be familiar with one company leading the market in the additive manufactured composite materials area. With 3D printers such as the award winning Mark Two, the Cambridge, Massachusetts based Markforged has already demonstrated how to work with composite plastics. Markforged has a number of industrial clients, such as Dixon Valve & Coupling, using 3D printing to make strong parts that used for tooling in their manufacturing process.

With Anisoprints use of composites, comparison between the two enterprises is inevitable.

In Russia this week Anisoprint will present the latest iteration of their continuous fiber reinforced polymer (CFRP) composite material 3D printer. The event is called, Additive Manufacturing of Continuous Fibers Reinforced Polymer Composite Materials for High Performance Structural Applications and features speakers from a consortium established to promote a framework for using 3D printed CFRP composite parts as a “more efficient alternative to traditionally manufactured composite components in specific industries such as the aerospace, automotive and wind energy markets.”

The consortium of 9 members, including Anisoprint, was formed after Paris composite event JEC World 2016. The group is coordinated by Austria’s Johannes Kepler University Linz, and includes enterprises from Austria, Lithuania and Russia.

3D Prints 15-20 times stronger than PLA

According to Anisoprint, currently there are “no affordable, versatile, and easy-to-use additive technologies available on the market, which allow manufacturing high performance parts, suitable for use in a wide range of products.”

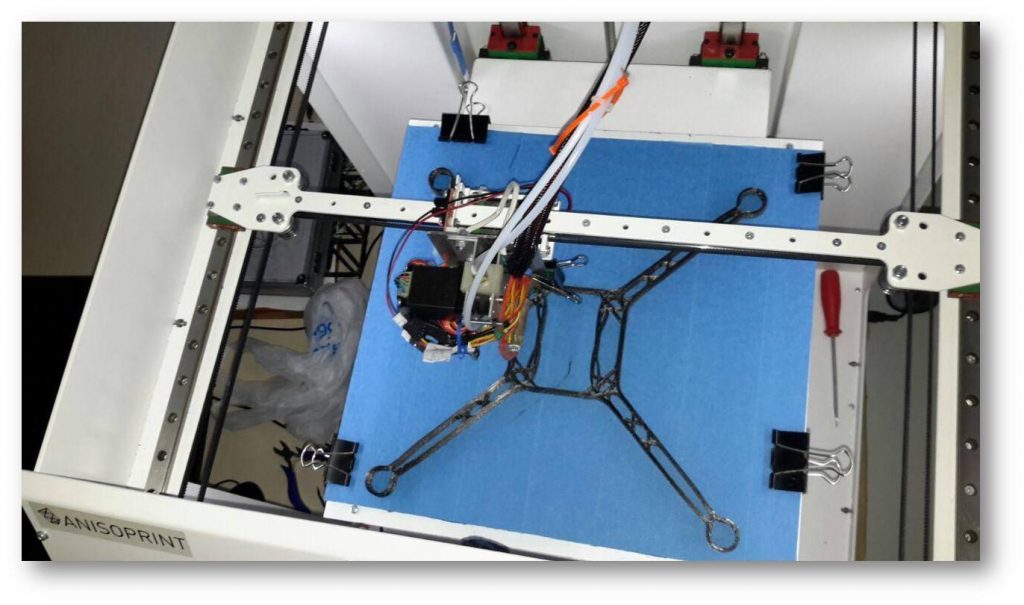

The Anisoprint 3D printing system aims to address this and the company promise that through introduction of continuous continuous fibers their 3D prints are “15-20 times stronger and stiffer” than those made by FDM systems in PLA. According to Anisoprint this means that the 3D prints are, “even stronger than aerospace aluminum.”

Anisoprint says, “Our technology is a revolutionary solution combining low equipment price typical for personal plastic printers with capability of producing high performance structural elements.” The 3D printer manufacturer also highlights that 3D prints 15 times stronger than neat plastic, 7 times stronger than plastic compounds and 4 times lighter than titanium are possible.

For all the latest 3D printing industry news from across the world subscribe to the most widely read 3D printing newsletter and follow our active social media accounts.

Featured image shows Anisoprint CEO Fedor Antonov demonstrating Anisoprint’s 3D printer to Prime Minister Dmitry Medvedev at Skolkovo Dmitry Medvedev. Photo via Sk.ru